It has therefore never been more urgent to address the challenge of plastic pollution Early in March, representatives from 175 nations endorsed an unprecedented and ambitious resolution at the UN Environment Assembly to end plastic pollution and forge an international legally binding agreement by the end of 2024. This makes it the most important international multilateral environmental deal since the Paris climate accord. This legally binding instrument should reflect diverse alternatives to address the full lifecycle of plastics, and the need for enhanced international collaboration to facilitate access to technology.

New regulations to foster the circular economy are just one example that reflects an underlying trend: rising demand for rPET, brand owners’ extended producer responsibility (EPR), and citizens’ environmental concerns can only pave the way for a boom in plastics recycling.

Today the most advanced technologies in terms of recycling prove that it is economically profitable to produce goods from recycled material. If PET bottle recycling is now well established, current technologies can further improve the recycling of PET trays and plastic films. For over 20 years, Pellenc ST has recovered from the fields and the ever-changing needs of its customers.

WASTE AND RECYCLING PLANT OPERATORS FACE 3 MAIN CHALLENGES:

Sorting Quality, Sorting Capacity, and Equipment Scalability

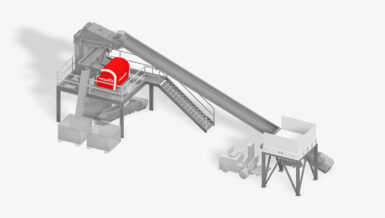

First, recyclers require more accurate sorting. Packaging materials are becoming more and more complex and optical sorters now must meet more demanding standards including food-grade quality. The FLOW Detection system was specially designed by Pellenc ST to address higher quality sorting. It combines a new spectrometer covering an extended NIR/VIS spectrum, as well as focused lighting. This combination enables the recovery of waste with higher levels of purity. In particular, this detection improves the handling of labels, and sleeves and accurately separates monolayer PET trays from PET bottles. Moreover, the profile detection option further improves the purity of target fractions by removing inerts and carbon black contaminants.

High yields are the second concern expressed by the market players. They need to massify streams and optimize the performance of their industrial tool to ensure business profitability. The Top Speed option introduced a few years ago by Pellenc ST has already demonstrated the possibility to handle input-stream variations. For instance, it addresses one of the key requirements of LDPE recyclers – higher capacities. With the Top Speed option, operators further increase sorting capacity by 50% while maintaining sorting performance, offering higher flexibility to tackle input stream quality variations.

The last requirement is to provide modular and scalable sorting solutions. Operators require sustainable equipment, able to adapt to technological advances. With the new Mistral+ CONNECT, Pellenc ST offers Future Proof sorting solutions to its customers. Thanks to the Central Nervous System (CNS) software platform, Plant operators have the possibility to integrate future technologies such as the IIoT, Watermarking, or Artificial Intelligence and upgrade their sorter to the latest technologies. The Holygrail 2.0 watermarking project on which Pellenc ST is working in partnership with the city of Copenhagen and Digimarc is a good case in point. Once the industrial test phase has been validated, Pellenc ST will be able to offer this additional detection unit to its machines in the form of a simple upgrade without having to renew the entire equipment.

Finally, the Mistral+ CONNECT includes a series of sensors connecting the peripherals of the Full Package to the Smart & Share monitoring tool. With connected and smart optical sorters, Pellenc ST offers new features, product data analysis, and higher-value service contracts in line with Industry 4.0 standards. These new sensors collect additional information to log and analyze equipment incidents, prevent conveyor failures, and jams, and analyze stream composition and distribution on the conveyor belt. To ensure smooth operation and efficient continuous improvement plans, all Mistral+ Connect sorters are delivered with a one-year free-of-charge service for plant operators to benefit from the experienced Pellenc ST service engineers. There is no better way to implement continuous improvement plans, maximize yields and ensure the highest plant availability rates. We offer high support and performant equipment to ensure profitable Waste & recycling business operations.

Pellenc ST sorting solutions are the new benchmark for operators aiming to modernize their industrial equipment to meet the new standards used by 4.0 sorting centers.