While food packaging plays a vital role in feeding people around the world, it also contributes to waste if not properly collected or recycled. The World Bank estimates global waste will rise by 70% by 2050, underscoring that recycling alone is no longer enough. The shift from a traditional linear economy — where products go from raw materials to waste — to a circular economy, where materials are reused, is now more urgent than ever.

Tetra Pak’s investment in circularity

In line with this goal, Tetra Pak invested one million euros in Recon Polymers in Roosendaal in 2023. Recon Polymers processes PolyAl from used beverage cartons into reusable raw materials for the plastics industry. PolyAl is the plastic and aluminum left behind after paper fibers are extracted from used cartons at paper mills. This investment has boosted recycling capacity to over 8,000 tons per year, enabling the recycling of about 30% of PolyAl from beverage cartons in France, Belgium, and the Netherlands.

From PolyAl to sustainable products

AVK Plastics, based in Balk, plays a key role in this collaboration. The company designs and produces high-quality plastic products from recycled materials using injection molding, including cover boxes and reusable transport pallets, sold through its subsidiary, Q-Pall. AVK Plastics also offers co-development and contract manufacturing services to clients who wish to incorporate recycled plastic into their products, with production facilities in the Netherlands, Denmark, and Germany. Driven by ambitious growth and sustainability goals, the company actively seeks partnerships within the supply chain to commercially tap into under-recycled plastic waste for both existing and new applications.

Through close collaboration, Recon Polymers optimized its recycling process, while AVK Plastics adjusted its infrastructure to handle the supply of recycled materials. As a result, recycled PolyAl can now be used in AVK Plastics’ material recipes for transport pallets. AVK Plastics has already processed 3,000 tons of PolyAl, making it one of the largest users of this material in Europe. With the support of Tetra Pak and Recon Polymers, AVK Plastics sees even more potential to expand the use of recycled PolyAl for both existing and new applications.

Boosting recycling capacity

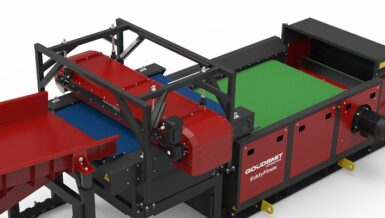

With its increased recycling capacity, Recon Polymers now supplies more recycled PolyAl, allowing AVK Plastics to use even more of this material in production. Led by CEO Dirk van Loon, Recon Polymers has significantly reduced energy consumption in the recycling process. Thanks to Tetra Pak’s investment, the company can now acquire the machinery needed to further optimize this process.

Strategic partnerships for a sustainable future

Frank Vandewal, Sustainability Director for France, Benelux, Germany, Austria, and Switzerland at Tetra Pak highlighted:

“Our partnership with AVK Plastics demonstrates how strategic and smart collaborations can enhance circularity in the packaging industry. Together, we’re increasing recycling capacity and reducing reliance on virgin materials. This not only raises the value of recycled materials but also encourages other companies to adopt circular practices. Consumers are becoming more aware of their environmental impact and are seeking sustainable solutions. With AVK Plastics, we’re able to offer innovative recycling solutions that meet consumer demands and contribute to a healthier planet.”

Arno Kanters, Managing Director at AVK Plastics, added:

“We have an ambitious growth strategy and sustainability agenda. Our goal is to become fully circular, turning recycled plastic into high-quality products with the lowest possible environmental impact. Our partnership with Recon Polymers to enhance their energy-efficient recycling process for PolyAl and provide recycled materials that fit our product recipes is a great example of constructive, open collaboration across the value chain. It shows what’s possible when partners are willing to work closely together on a shared agenda. This is what we call a true partnership.”