Once a niche technology used mainly in autonomous vehicles, LiDAR is increasingly being adopted across various industries, including waste management, where it enables automated volume monitoring, precise inventory control, and data-driven process optimization.

Automated Fill-Level Monitoring in Waste Storage Areas and Bunkers

Waste collection and storage operations often rely on manual inspections or rough estimations to determine fill levels. These outdated methods can lead to under- or overutilization of storage capacity, inefficient logistics, and even safety hazards such as spills, unstable piles, or equipment risks —challenges that digital waste management solutions can help overcome.

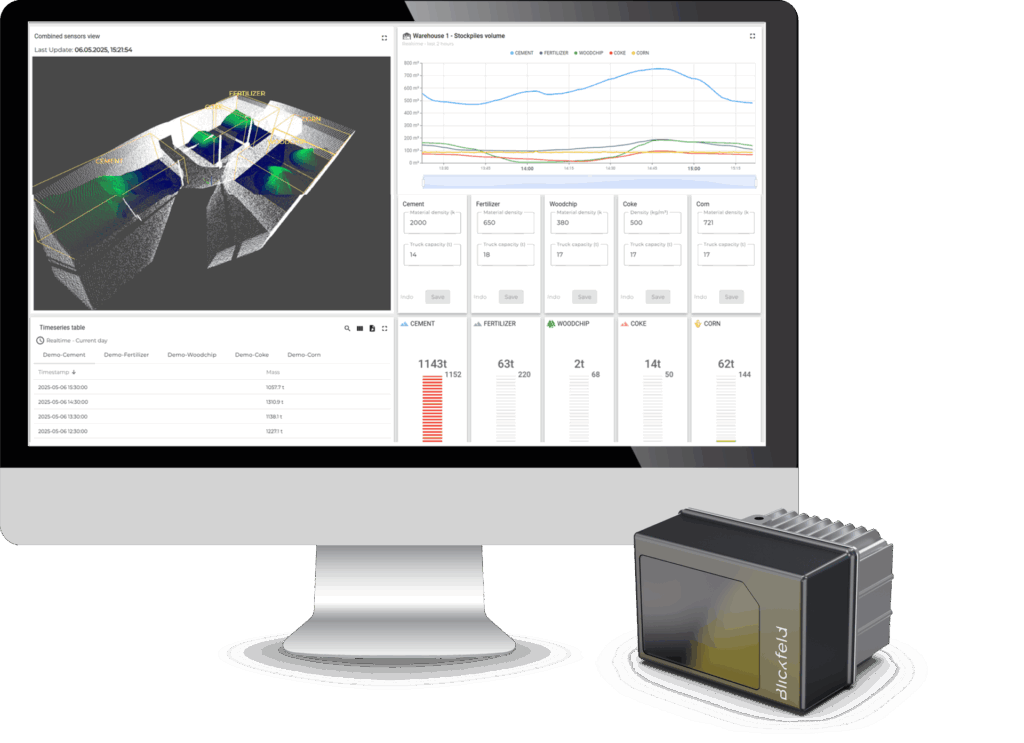

LiDAR sensors provide a modern alternative. Mounted in storage halls, silos, or over waste bunkers, LiDAR systems continuously scan the surface of stored material, producing high-resolution 3D point clouds in real time. From this data, software algorithms calculate exact fill levels and volumetric changes, delivering on-demand insights for operators.

Unlike other optical systems such as cameras, LiDAR is unaffected by low light, dust, glare, or adverse weather, making it exceptionally robust in harsh industrial environments like waste bunkers or incineration plants.

Real-Time Inventory Management: A Use Case from Cireco

Cireco, a leading Scottish waste recovery company, illustrates the practical value of LiDAR-based volume monitoring. Previously, the company relied on vehicle scale data and visual estimates to assess material volumes—methods that often led to planning inaccuracies and underutilized capacity in its sorting operations.

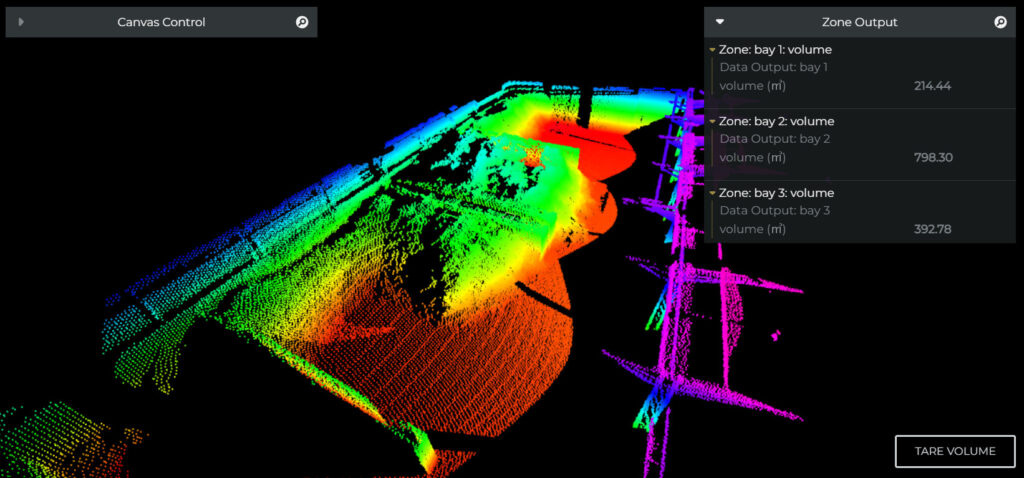

To improve transparency and control, Cireco implemented a LiDAR solution from Blickfeld. Three ceiling-mounted sensors now cover the entire storage area, continuously generating live 3D data. This data is processed by specialized software to calculate the exact volume of waste in each bay—accurate down to the ton and updated in real time.

The results have been clear: Cireco can now reliably forecast available material, better utilize storage space, and optimize plant scheduling. According to CEO Robin Baird, the system has improved throughput planning, internal logistics, and billing precision—addressing several operational pain points with one integrated solution.

Data-Driven Compliance with CO₂ Taxation Across Europe

Precise volume measurement is also playing a growing role in helping waste-to-energy (WtE) operators meet carbon taxation and emissions reporting requirements. Across Europe, regulatory frameworks are tightening: in several countries, incineration volumes must now be documented with high accuracy as a basis for calculating CO₂ taxes or for inclusion in national emissions trading schemes.

Traditional estimation methods—such as truckload counts or manual inspections—often fall short in precision and traceability. This creates financial and legal risks, including overpayment, underreporting penalties, or non-compliance with audit standards.

LiDAR-based monitoring delivers the level of data quality required for these new frameworks. By providing continuous, high-resolution volume data, the technology supports automated CO₂ reporting, improves transparency, and ensures reliable documentation for authorities. At the same time, operators can plan incineration processes more effectively, optimize bunker turnover, and reduce the risk of exceeding emissions limits—all based on a consistent, real-time view of their input material.

Improving Safety and Situational Awareness: The MVV Gersthofen Example

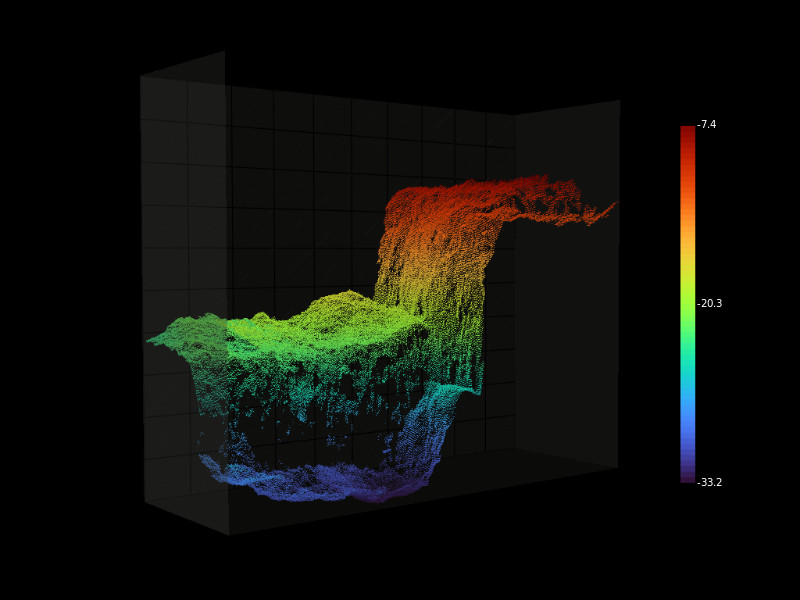

In addition to regulatory compliance and operational efficiency, LiDAR-based volume monitoring also enhances safety—particularly in waste bunkers, where unstable material formations can pose serious risks. At MVV Industriepark Gersthofen, a refuse-derived fuel (RDF) cogeneration facility in Germany, operators faced challenges caused by irregular waste accumulations along bunker walls. These so-called “cornices” were difficult to detect manually and repeatedly damaged crane systems, disrupting operations.

To mitigate these risks, MVV implemented a LiDAR-based monitoring solution using multiple sensors to cover the entire bunker space. The system continuously calculates the fill level in defined zones and automatically alerts operators when critical thresholds are exceeded. This enables timely intervention before safety or operational issues arise.

Since its introduction, the solution has significantly reduced manual inspections and wear on equipment, while improving planning accuracy and real-time awareness of bunker conditions.

A Future-Proof Technology for a Digital Waste Management

As the waste and recycling industry embraces the opportunities of digitalization alongside increasing regulation and sustainability demands, LiDAR is proving to be far more than a niche technology. It is gaining traction in waste management, delivering significant benefits that help future-proof operations. From real-time inventory monitoring and optimized plant operation to regulatory compliance and improved workplace safety, LiDAR delivers tangible value across the entire waste management value chain. Its ability to provide high-resolution, reliable data—even under harsh environmental conditions—makes it a cornerstone of digital waste management. For operators seeking greater efficiency, transparency, and resilience in their processes, LiDAR is not just a technological upgrade—it is a strategic enabler for the future.