On a daily basis, trucks deliver a constant supply of new material for the shredder, which is fed by the SENNEBOGEN 17-ton material handler. The fact that the machine can handle materials in quick cycles contributes to just-in-time processing and to the materials being moved on again, meaning the storage areas do not stay full for unnecessarily long periods of time.

BTU Hartmeier in Unterschleißheim, near Munich, Germany, has perfected its on site processes, it is almost like watching a well organized ant colony. In a matter of minutes waste management vehicles and transport containers pull up, their contents are unloaded, sorted, shredded, and prepared for their onward journey. What are the advantages of doing this? Less storage space is required, and the available resources are processed more quickly and efficiently. At the heart of the site, under the rainbow created by the water spray from the dust reduction system, the SENNEBOGEN 817 E series can be found, sorting the delivered material and loading it into the shredder to be crushed.

Powerful and Maneuverable, Ideal Characteristics for Narrow Sorting Locations

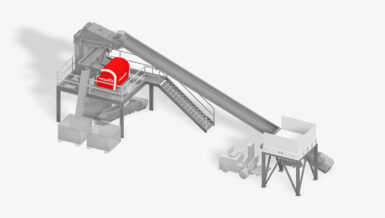

Being just 2.54 m by 4.61 m, the 817 E series is SENNEBOGEN’s most compact material handler and it can really show off with its efficient 97 kW new generation, stage V emission standard conforming engine. At BTU Hartmeier the agile machine with its 9 m long equipment is not just used to feed the shredders, but also helps to sort cardboard packaging and load trucks. The narrow front radius of the material handler is crucial in carrying out the latter task. As the operator can maneuver very close to the loading area and can easily get the cab into an elevated working position, it is more convenient to look inside the container of the truck, which also makes the positioning of materials safer and faster. Thanks to the particularly sensitive joystick controls of the 817 E series, heavy loads, such as construction waste, can be transported to their destination quickly. The original SENNEBOGEN sorting grab is perfectly matched to the machine’s hydraulic circuit and is always supplies with exactly the amount of hydraulic oil that is actually required for the grab task, thereby saving energy.

Designed for Demanding Applications

As the saying goes, “you cannot make an omelette without breaking eggs.” The same is true of recycling activities. It is often very gruelling work, but the ultimate goal is always to make a positive contribution to improving the environment by recycling materials. BTU Hartmeier’s recyling specialists are ideally equipped for the conditions on site: The dust reduction system on the roof of the half-open storage facility reduces the amount of fine particles in the air, as the particles combine with water vapor in the air and fall to the ground at the facility, instead of spreading out into the surrounding environment.

Likewise, those responsible for the fleet take care to ensure that the machines being used are environmentally friendly, efficient and suitable to the site’s conditions. SENNEBOGEN’s 817 E series offers just such a range of features that support people and machines in challenging recycling applications. Both the engine compartment and the cab interior are protected from dust particles by SENNEBOGEN’s diverse range of protection packages. A reversible fan to discharge dust is fitted as standard across the series, protecting engine components and increasing their service life. An optional cyclone pre-separator is also available, as well as an active carbon filter for the Multicab ventilation system.

The series standard elevating Multicab also provides the operator with an ideal overview of the work area from a height of around five meters and, with the 9 m equipment, they are able to carry out precision sorting tasks at ground level or load the shredder with centimeter accuracy. The more precisely the material is loaded and sorted, the more efficiently and safely daily processes on site can be organized. In addition, the two side windows and the continuous windscreen, which is equipped with safety glass as standard, provide an unrestricted all-round view across the whole area – ideal for quick yet safe loading cycles.