This comprehensive system addresses four major challenges: heterogeneous waste, contaminants, variable moisture, and operational cost. By leveraging AI algorithms trained on thousands of material samples, the platform can identify over 20 waste categories—down to black plastics and composite packaging—at line speeds exceeding 2 m/s.

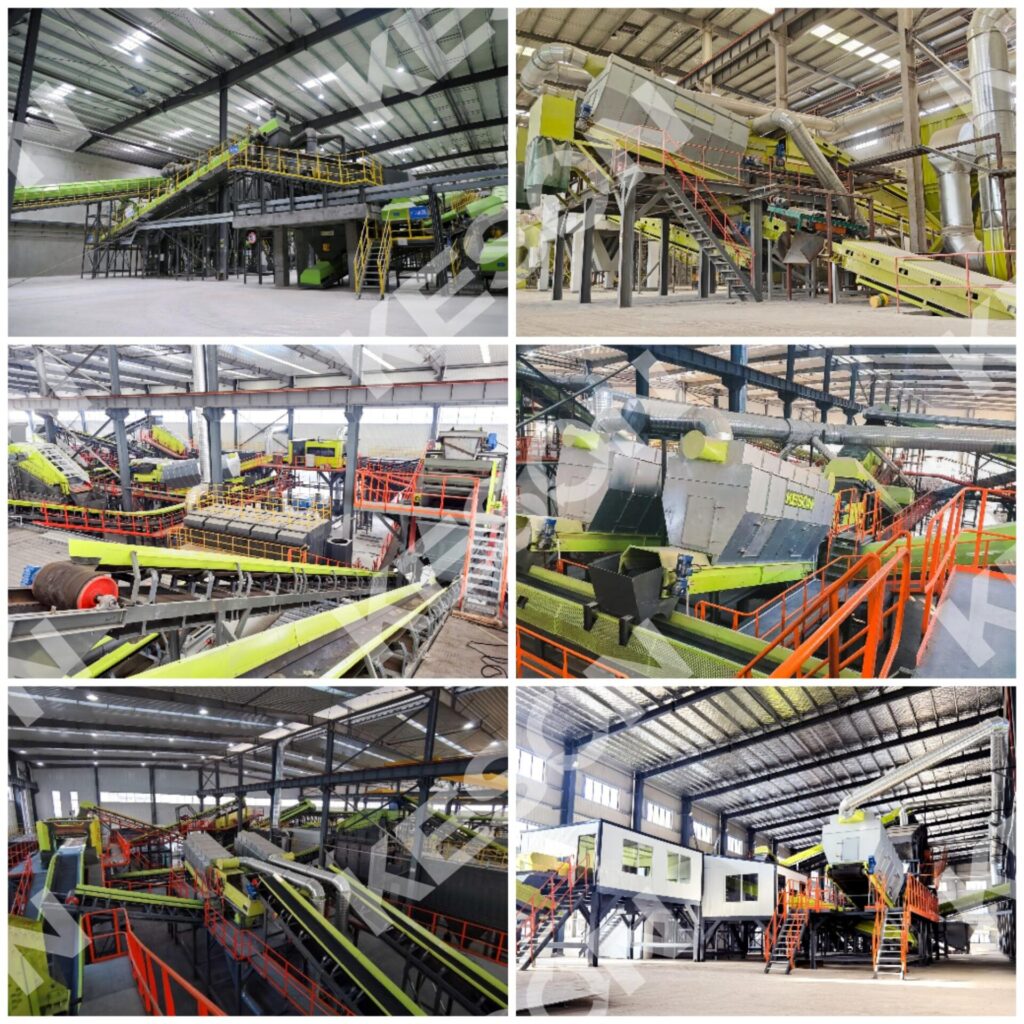

System workflow:

- Pre-treatment & Bag Opening: Automated bag splitters and trommel screens prepare a uniform feed.

- Coarse Separation: Over-sized items, ferrous & non-ferrous metals are removed.

- Density-Based Sorting: Air-density classifiers separate light from heavy fractions.

- AI Fine Sorting: High-speed cameras capture real-time images; the AI engine recognizes material types by shape, color, texture, and reflectivity; precision air nozzles then eject targeted objects.

- Baling & Packaging: Each sorted fraction is mechanically baled for downstream processing.

The process

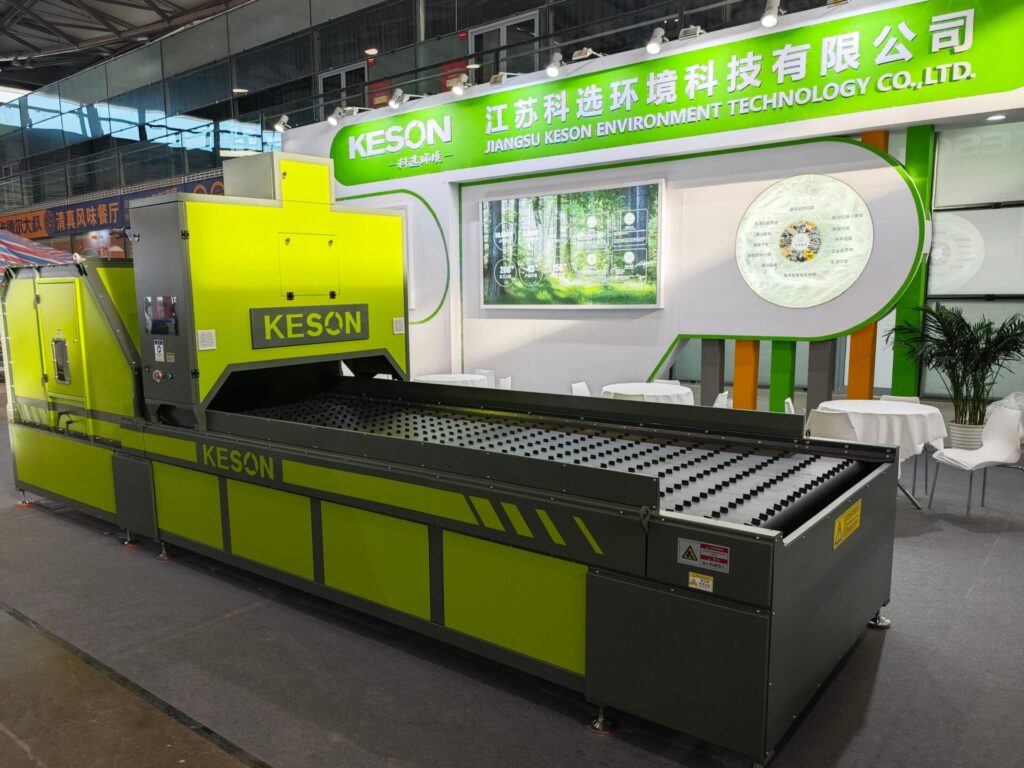

Keson’s equipment is specifically engineered to handle wet, sticky, and entangled materials commonly found in household waste. Screens and conveyors are designed with anti-clogging, anti-wrapping, and moisture-tolerant features, ensuring stable operation even under harsh conditions. Key components such as shaft screens, anti-winding rotating sieves, and wear-resistant shredders prevent downtime due to jamming or residue buildup.

The AI module enhances identification precision by targeting difficult materials like black films, multilayer laminates, and food-contaminated plastics—materials that often escape traditional NIR sorting. The deep learning model continuously evolves, adapting to new waste types and improving over time.

The entire system is modular, allowing it to adapt to various waste streams—not just MSW, but also construction and demolition waste, bulky waste, industrial residuals, and more. It’s scalable, easy to deploy, and can be customized to local site conditions.

In tests, Keson’s AI-driven line achieved a 95% purity rate for plastics and a 90% recovery rate for paper—benchmarks 15–20% higher than conventional setups. By raising material quality, end-users benefit from higher commodity prices and reduced contamination penalties.

Currently, Keson has deployed pilot projects in multiple locations. In most cases, during the first quarter of operation, residual waste was reduced by 30% and the recycling rate increased by 25%.