High sorting efficiency thanks to sensor fusion and HSI camera

“Our new BRT HARTNER AS Automatic Sorter follows the combination of acceleration belt, optical sensors and compressed air sorting that is already firmly established on the market,” explains Andre Berlage, Executive Manager of BRT HARTNER. “However, while many suppliers still rely on near-infrared for sorting, our BRT HARTNER AS is equipped with the latest generation of hyperspectral imaging [HSI].” This state-of-the-art camera system not only generates images with excellent resolution but can also provide important information about the material properties.

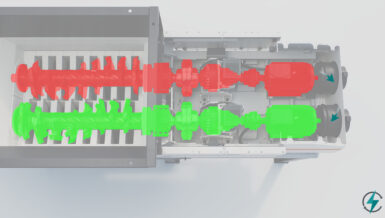

In addition, the use of a sensor fusion base concept sets the BRT HARTNER AS apart from other solutions on the market. Thanks to sensor fusion, the measured values of all installed sensors (NIR / colour / 3D / metal) are evaluated directly as raw data and there are no further interfaces. Thus, the data from all sensors is forwarded for analysis without loss. The detection algorithm has been trained on extensive data material and therefore proves to be extremely precise. The user can recognise the material assignment of the input material live on the intuitive display. In the case of lightweight packaging, for example, not only is the material assignment shown in colour, but the type of packaging is also recorded and noted. “Another advantage of sensor fusion technology is the high degree of flexibility,” emphasises Hendrik Beel – Managing Director at RTT System GmbH. “This means that new sensors can be integrated into the system at any time at raw data level. This applies, for example, to the retrofitting of 3D sensors, metal sensors or future marker technologies.”

If required, the standard spectral AI can also be expanded to include object AI (a colour camera must be installed in this case), which recognises and separates out precisely predefined objects. Beel emphasises: “This makes the new Automatic Sorter an investment with future potential that can be adapted to changing requirements or stricter specifications and the latest sensor technology at any time.”

Versatile and easy to maintain

The BRT HARTNER AS is designed for sorting precisely those materials that cannot be processed using conventional separation methods. The AI can not only process all of the recorded data without loss and thus not only reliably identify the material but also differentiate objects into predefined object classes. This allows precise statements to be made about the material, ensuring that different types of plastic can be precisely differentiated. “The Automatic Sorter is, among other things, our answer to the higher requirements in plastics recycling. After all, the increasing practice of chemical recycling means that there is a growing demand for precise separation of the different plastic fractions,” states Berlage. “It is therefore also perfectly suited for separating the high-calorific fraction in substitute fuel production. In principle the Automatic Sorter can also be used for removing impurities in general.”

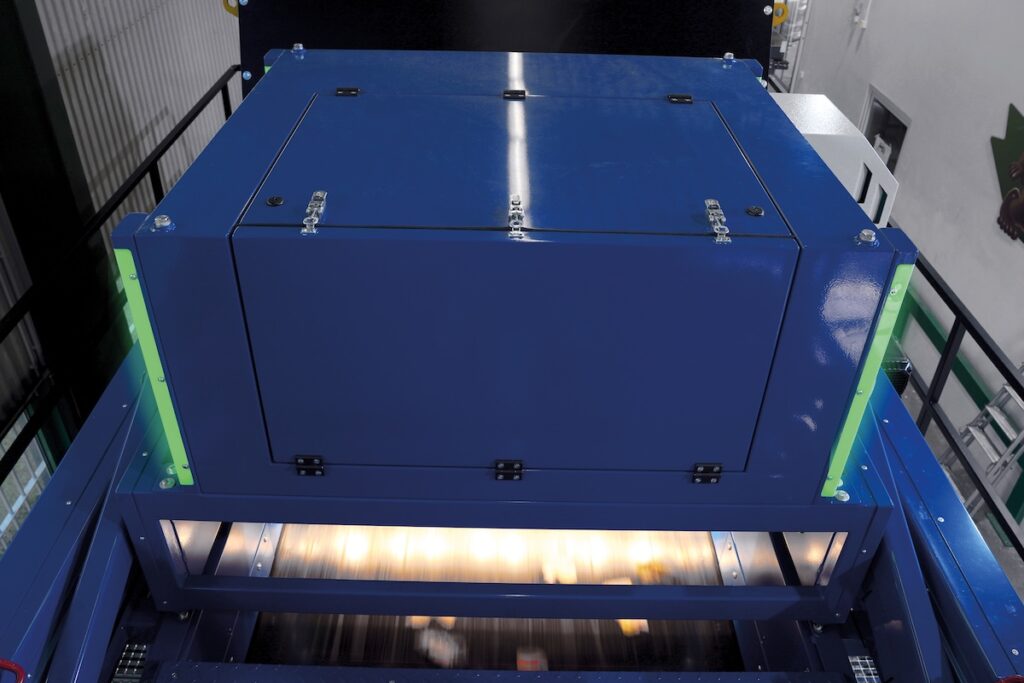

Another advantage of the BRT HARTNER AS is the choice of light sources. The use of special light sources has been deliberately avoided and they can all be purchased freely from retailers or online. Consequently, they are also very cost-effective. “Compared to the usual solutions on the market with HSI systems, the Automatic Sorter furthermore requires around 50 % fewer light sources,” elaborates Beel.

The BRT HARTNER AS is also designed for maximum ease of maintenance. For example, a platform can be extended inside, which simplifies servicing activities in the separating unit. The sensor unit can be optionally equipped so that maintenance or cleaning can be carried out conveniently from a maintenance walkway.

Cooperation between two recycling experts

BRT HARTNER developed the Automatic Sorter in cooperation with RTT System GmbH. “The collaboration between our companies brings clear advantages for both sides,” explains Berlage. “We have an extensive global sales network with many valuable contacts and more than 30 years of experience in machine as well as plant engineering, while we benefit not only from RTT System GmbH in-depth expertise, but also from the high level of development of sensor-based systems. We are therefore very pleased about this strategic partnership.” BRT HARTNER is an established player on the international market in the field of stationary recycling and plant technology. In addition to the BRT HARTNER BO Bag Opener as its traditional flagship, the company is also known for its mechanical separation systems. These include ballistic separators, trommel screens, star screens and even complex air separators. RTT System GmbH, on the other hand, is a recognised specialist in precise analysis systems for optical quality and purity control. The company also offers the Picksort, for example, a combined solution of optical detection and robot technology for separation.