In modern recycling plants, efficient material classification is a decisive factor for profitability and operational reliability. Vibrating screens are essential to this task – operating almost continuously to sort and separate materials. Yet, despite their critical role, most of these machines are not systematically monitored. This leads to inefficiencies, unplanned downtime, and reactive maintenance practices.

The few existing condition monitoring systems in recycling plants are not designed with vibrating screens in mind. They may track bearing vibrations, power consumption, or oil quality – but these are indirect indicators, and often fail to detect early-stage mechanical issues.

Maintenance is still largely based on gut feeling, manual inspection, or worse – waiting for failure. The result: inefficient performance, shorter machine lifespans, and avoidable production losses.

Smart Vibration Sensors and Advanced Measurement Technology

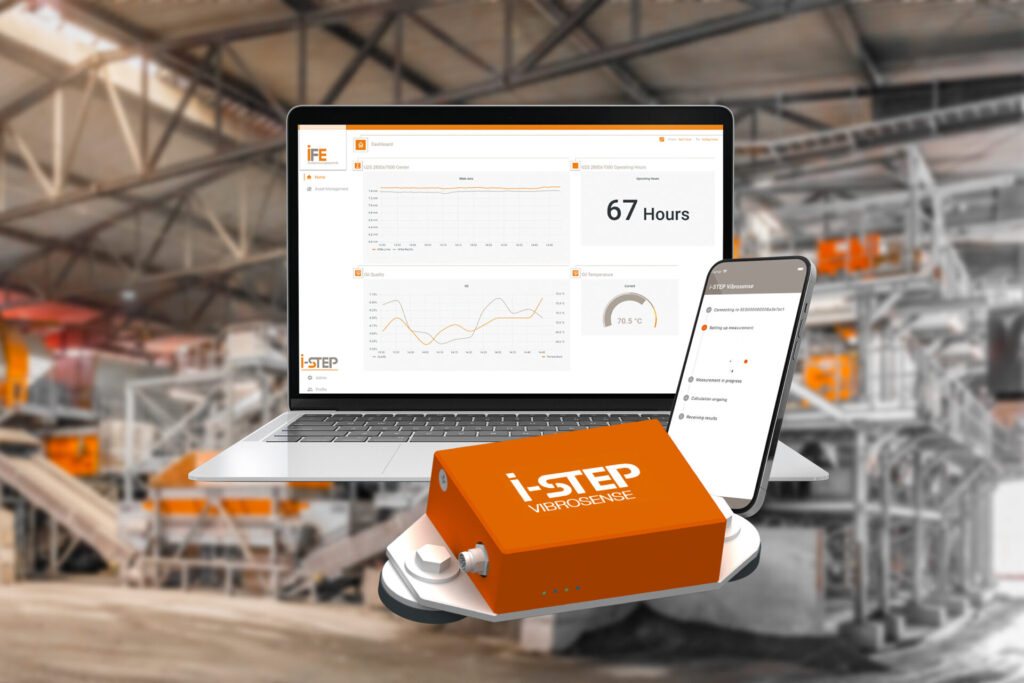

IFE Material Handling – a manufacturer of tailored vibroconveyor, screening, and magnetic technology solutions – has developed a breakthrough digital optimization system: i-STEP. With i-STEP, operators can monitor and optimize their material processing machinery and more using intelligent vibration analysis tools. At the heart of this new product line are i-STEP Vibrosense sensors and a powerful cloud-based platform – the next evolutionary step in digital plant monitoring and control.

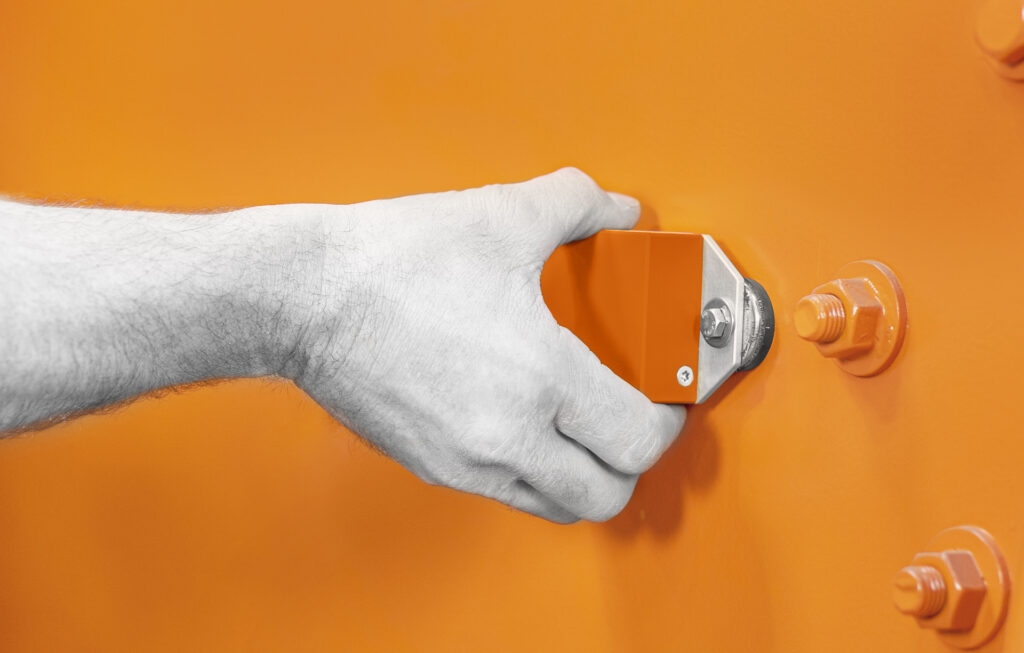

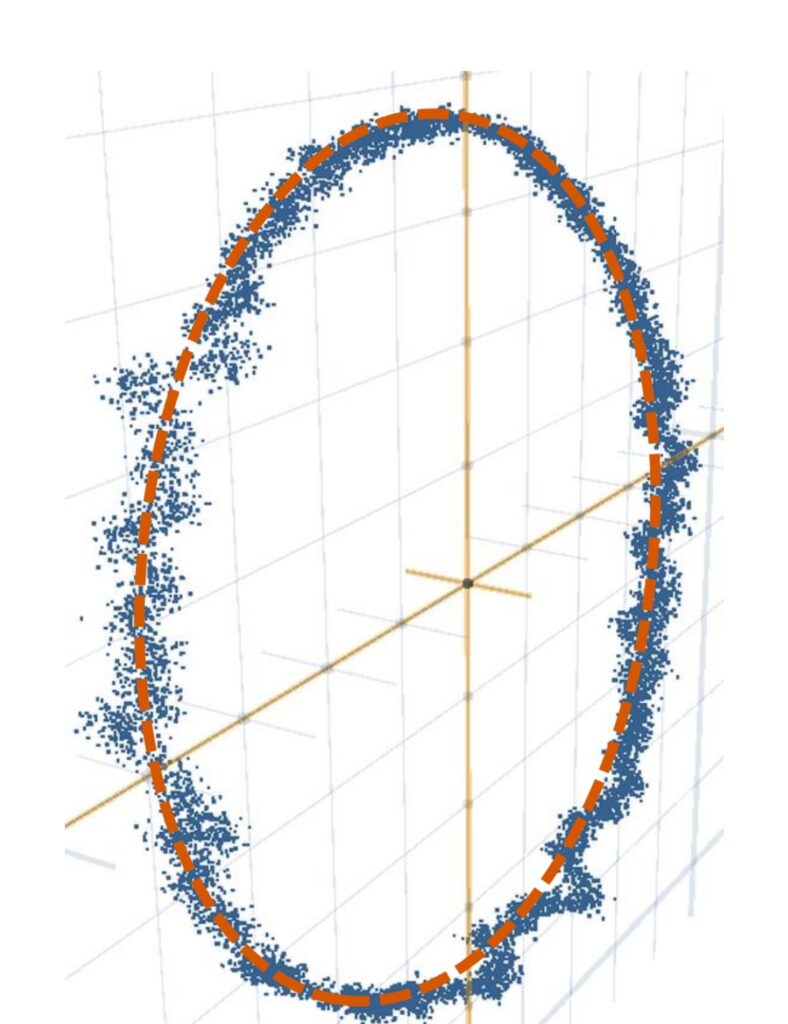

i-STEP Vibrosense sensors are engineered to capture three-dimensional vibration data directly from vibrating screens and conveyors. Available in battery-powered and wired versions, these sensors are magnetically attached to machines or permanently installed for continuous monitoring. Using accelerometers similar to those in smartphones but optimized for industrial use, the sensor collects thousands of data points per second, capturing vibration behavior along all spatial axes. It then generates a 3D point cloud that is mathematically fitted with an ellipse, reducing the data to core indicators such as main/minor axes, vibration angle, frequency, and cross-vibration. Using the i-STEP Vibrosense app on smartphone or tablet the system allows to generate substantiated vibration analysis which can then be shared as PDF file.

The next evolution is waiting

Building on the foundation of the i-STEP Workbench, IFE is preparing to launch the next evolutionary step: the i-STEP Operator. This new platform will enable seamless integration of various sensors and machines – including third-party equipment – into a unified system. With user-friendly tools and customizable analytics, the i-STEP Operator will serve as a central hub for machine monitoring, maintenance planning, and documentation management. In doing so, IFE continues to deliver smart, scalable solutions tailored to the needs of modern material processing operations.