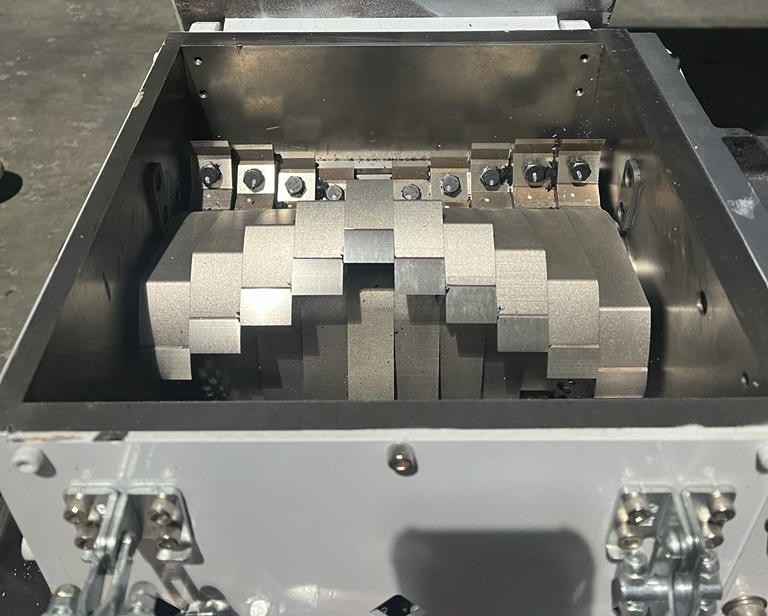

At a leading European textile research center, a new ITS laboratory grinder is helping scientists tackle that very challenge. Designed by ITS – Shredding & Grinding Solutions, the compact yet powerful system enables precise reduction of textile fibers for testing, analysis, and reuse — from coarse shredding to fine micronization.

While it may look like a small-scale machine, the grinder is playing a big role in advancing research on fiber recovery, material circularity, and sustainable production methods. It allows researchers to simulate real-world processing conditions at laboratory scale, a critical step in understanding how fibers behave during recycling and how material properties evolve when reused.

From textile waste to new material opportunities

Today’s textile waste streams — a mix of natural, synthetic, and blended fibers — are notoriously difficult to recycle efficiently. To address this, laboratories across Europe are studying not only how to separate and classify fibers, but also how to trace them through production cycles and quantify the environmental impact of reuse.

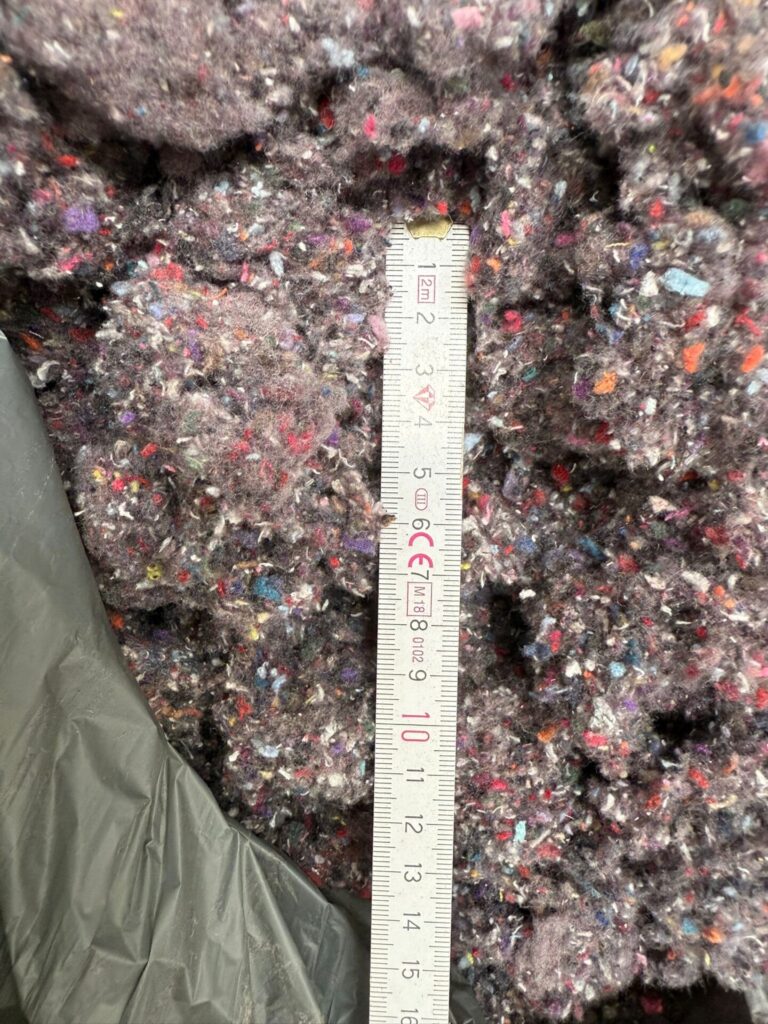

The ITS grinder contributes directly to this mission by allowing controlled grinding and reproducible testing conditions. “The flexibility of the system lets us process everything from cotton and wool to technical synthetics,” says one researcher involved in the project. “That precision makes it possible to analyze fiber degradation, contamination, and mechanical properties after recycling.”

One of the most intriguing applications under study is the micronization of synthetic textiles into fine powders — a process that could give worn-out garments a second life in 3D printing and additive manufacturing. This interdisciplinary approach bridges textiles and advanced materials engineering, showing how yesterday’s fabrics might become tomorrow’s high-performance components.

Technology and sustainability go hand in hand

For ITS – Shredding & Grinding Solutions, headquartered near Milan and active internationally, the collaboration reflects a broader commitment to innovation in material recovery. With over 25 years of experience designing industrial shredders, granulators, and complete recycling systems, ITS brings the same engineering rigor to laboratory-scale solutions.

“Our goal is to make precision and sustainability compatible,” says an ITS representative. “By adapting industrial know-how to the research environment, we’re helping scientists and companies explore new recycling pathways and validate circular economy models in real conditions.”

Enabling the future of circular textile

As textile manufacturers face increasing pressure to reduce waste and carbon impact, partnerships between technology providers and research institutions are becoming essential. The ITS laboratory grinder is more than just a machine — it’s a bridge between engineering and sustainability, between research and industrial practice.

By empowering laboratories to explore the full potential of fiber reuse, ITS is helping the textile sector move closer to a truly circular model — where every thread, every fabric, and every innovation counts.