Defined grain sizes for stable extrusion

Every detail counts in the recycling process: from pre-sorting to particle size. WURSI first processes sorted plastic waste manually and feeds it into the two WEIMA shredders via a conveyor belt. There, the material is shredded to between 30 and 100 millimeters, depending on the screen configuration. The resulting flakes form the basis for a homogeneous melt in the extrusion process. “We have been very satisfied since we purchased the first machine. We quickly bought the second one and hope to integrate the third one next year,” reports Managing Director Javier Perez.

Process control with integrated safety

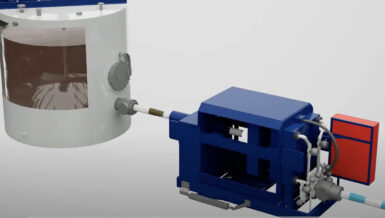

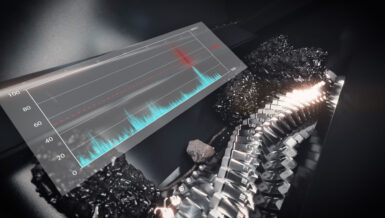

The material is fed directly into the extruder either via a conveyor belt or a suction system. A metal detector between the shredding and extrusion stages reliably protects the system from foreign objects. WURSI tests each batch for melt index, density, and color stability in its in-house laboratory. This is an integral part of quality assurance in order to detect process fluctuations at an early stage.

Machine design for continuous operation

The WEIMA W5.14 shredder is designed for demanding plastic applications. The V-rotor with a diameter of 500 mm and a length of 1,400 mm ensures uniform shredding even with tough materials. The Siemens PLC control system with touch panel allows precise adjustment of the operating parameters. The hydraulically opening screen basket and the generous inspection flap significantly reduce downtime during maintenance or screen changes. WURSI 1 / 5 uses interchangeable screen segments to be able to react flexibly to material differences – an advantage with changing polyolefin streams.

Cooperation with clear communication

WURSI and WEIMA are linked by a pragmatic partnership. “From setup to after- sales service, we have great confidence in WEIMA and hope to continue working together for many years to come. WEIMA gave us a good feeling right from the start and enabled us to develop a close, family-like relationship. We really appreciate that,“ emphasizes Perez. ”Whether it’s problems, adjustments, or new ideas – there’s always a quick response and good cooperation. That’s why we chose WEIMA.”

Communication is direct and straightforward: a factor that is just as important in ongoing operations as machine performance or energy consumption.

Recycling as an industrial process

WURSI does not regard plastic recycling as an ecological flagship, but as a technically demanding value-added process. The combination of mechanical precision and quality-oriented process control results in a regranulate that meets the requirements of modern plastics processing and thus enables a genuine material cycle.