Modern briquetting remains straightforward, but this simplicity is due to the know-how that briquetting press manufacturers have developed over time. Today, most briquetting presses are produced using technically advanced and highly automated technology. At C.F Nielsen and RUF Briquetting Systems (mother company of C.F. Nielsen) we manufacturer mechanical, hydraulic and screw extruder briquetting lines.

In a historical context, commercial briquetting is relatively new, with the first industrial plants dating back to the latter part of the 19th century. With our 135 years of existence, C.F. Nielsen, have been involved in most facets of the briquetting industry. Whenever an exciting new inquiry reaches us, we approach it with curiosity and innovation. In the following sections, we will explore various applications of briquetting, highlighting its potential to promote sustainability in numerous industries.

Briquettes for CHP and District Heating Plants

The first place to mention is where it all began: the Nordic countries. C.F. Nielsen briquetting presses have long been used by sawmills and wood processing companies across Scandinavia. Supplying briquetting lines for the wood industry in Sweden, Norway, Denmark, and Finland created the base for C.F. Nielsen, and these markets remain important today.

The sawmills in Scandinavia typically produce briquettes and sell them to district heating plants or Combined Heat and Power (CHP) systems. Briquettes have similar burning capabilities to pellets and often come with lower operational expenses due to reduced electricity, labor, and maintenance costs. This makes them a flexible and cost-effective alternative. Compared to other biomass options such as wood chips, wood briquettes generally offer higher energy efficiency, better combustion characteristics, easier handling, and lower environmental impact. These factors make wood briquettes a preferred choice for many applications where efficiency, reliability, and environmental considerations are crucial.

Briquetting presses can handle various raw materials, and the briquette size can be adjusted to fit different industrial boiler systems. As a result, many CHP systems and district heating plants use briquettes for their affordability and adaptability. At C.F. Nielsen, we manufacture briquetting presses in different sizes suitable for sawmills and wood processors with 500 to 100,000 tons of byproducts available per year.

Briquetting: A Growing Trend for Domestic Fuel

C.F. Nielsen began developing consumer briquetting solutions at the beginning of the 21st century, as consumers started to demand efficient and environmentally friendly solutions for heat generation. Since then, we have worked hard to become the leading manufacturer of mechanical briquetting machines for the consumer segment and now we have a lot of inquiries also for hydraulic briquetting.

In most cases, the raw material used for consumer briquetting comes from wood residue because it has low ash content, thereby providing a better and longer burn in the briquettes. However, it is also possible to use raw materials such as wheat straw and miscanthus residue for this purpose. This is often the case for industries based in countries where other materials are more readily accessible than wood, or where agriculture is a primary industry.

In recent years, as the focus on renewable energy has grown, the applications for briquettes have expanded concurrently. Consumers require green energy that is economically competitive and convenient. On both attributes, briquettes prevail over traditional domestic fuel sources. Today, briquetting is therefore gaining renewed attention and is becoming a real alternative to conventional firewood and coal. Briquettes simply burn hotter and cleaner, are cheaper to buy, and are much easier to store and handle. Consumers all over Europe have, over the years, slowly but consistently discovered these advantages, and over the last two years, interest has been growing rapidly. Consequently, prices and demand over the last 4-5 years have been higher, and suppliers have been struggling to keep up with the progressive market.

There is a long tradition of using consumer briquettes in regions such as the United Kingdom, France, Germany, the Balkans, and Scandinavia. Other countries are also increasing their usage, and in North America, there is a significant rise in demand, particularly in the colder regions of the northeast and northwest. In Italy, many restaurants and pizzerias use briquettes because they burn for a long time and at high temperatures, ideal for stone ovens. Consequently, the focus in this segment lies in selecting and preparing the highest quality hardwood before it reaches the briquetting presses.

Briquetting: A Flexible Choice in Gasification

Gasification technology has been around for many years, with coal traditionally being the primary raw material. However, advancements in technology during the late 20th century, coupled with a growing interest in alternative energy sources, expanded the use of gasification to a wider range of feedstocks, including biomass and waste materials. Consequently, it is only in recent years that gasification has become a focus area for C.F. Nielsen and briquetting.

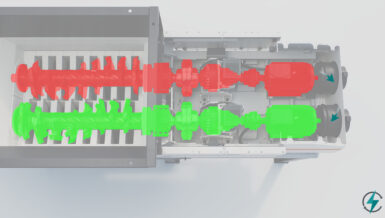

Many biomass by-products, such as dust and smaller particles, including various types of agricultural raw materials, cannot be used directly in a gasifier. However, by processing these raw materials into high-density briquettes, they can be transformed into valuable fuel for the gasification process. The C.F. Nielsen mechanical press is an ideal and proven solution for gasification due to its ability to produce high-density briquettes in a variety of shapes and forms. Typically, Ø40, Ø50, or Ø60 mm short briquettes (pucks) are used, which have proven to be an ideal size for some gasifier technologies. These mechanical presses are flexible in handling difficult raw materials, capable of briquetting materials with a moisture content of up to 20% and particle sizes up to 25 mm. This means less preparation of the biomass is required compared to alternative methods. RDF, MDF, wood, and agricultural by-products are all used as raw materials.

Torrefied Briquettes: An Alternative to Fossil Fuels

Torrefied briquettes are called “the new coal” because they are basically a clean copy of coal. This is why power stations can go green by only switching the fuel instead of making costly modifications to the power stations. Torrefied briquettes have similar storage, shipping, and combustion properties to coal. At C.F. Nielsen, we have a specialized briquetting solution developed for torrefied biomass, which can replace coal in power plants. To replace coal, our machines can produce briquettes in diameters from Ø50 mm to Ø75 mm. The briquettes can be shipped in bulk and shredded or downsized.

At C.F. Nielsen, we have tested torrefied raw materials from many different production plants all over the world, as well as sold plants for testing and production. This has enabled us to develop a unique application for torrefied wood that can downsize the raw materials through our precompression and die system. The machines can handle raw materials above 100°C, and they have a considerably lower power consumption per produced ton than any alternative on the market.

Conclusion

Briquetting is affecting the way industries manage and utilize biomass and waste materials. By converting what was once considered waste into valuable energy resources, briquetting is not only promoting sustainability but also offering economic benefits across various sectors. At C.F. Nielsen, we are proud to be at the forefront of this innovative field, providing solutions that address the world’s growing energy needs while preserving the environment. As we continue to explore new applications and improve our technologies, we remain committed to advancing briquetting as a cornerstone of a sustainable future.