This requires recycling materials flows that have as high and as consistent a quality as possible. It is only with efficient sorting technology that resources can be continually recycled. The STEINERT XSS T uses X-ray transmission (or XRT for short) to reliably achieve extremely high purity levels when recycling aluminium. EVO 5.0 is the latest evolutionary stage. Several customers explain here why they are so impressed with the equipment.

More and more companies are looking to save resources and expand their use of secondary raw materials. This approach can deliver a significantly lower carbon footprint and improve the security of supply.

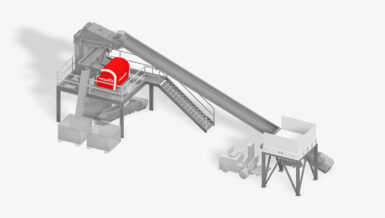

STEINERT has long been an important partner to metal recycling firms. Its technology for dry density separation has been successfully established for a number of years now. The systems are based on x-ray transmission and are designed especially for separating heavy and light metals in metal processing. The STEINERT XSS T produces extremely pure aluminum. The sorting equipment’s detection rates are so precise that it can achieve an aluminum purity of 99.8 %.

EVO 5.0, the latest version, has been available since 2021. Since then, noteworthy developments include automatic x-ray monitoring and automatic calibration of the x-ray sensors, as these ensure a consistently high detection and sorting quality without any fluctuations.

Alongside heavy/light metal separation, separating out wrought and cast aluminum is another essential application. This application is particularly important for marketing the secondary raw material.

The enrichment of solid magnesium is also key to the quality of secondary aluminum. Since EVO 5.0 and using what is known as multilayer data evaluation, the system has provided more distinguishing criteria for particularly challenging sorting tasks, such as detecting magnesium.

By separating free magnesium, the recycled aluminum produced can be used much more flexibly for recipes in the smelting furnace.

Numerous stories of success demonstrate the efficiency of the STEINERT XSS T EVO 5.0.

Sorting from incinerator bottom ash residue

The Scanmetals group of companies has three sites in Europe where it produces non-ferrous metals out of incinerator bottom ash (IBA) from waste incineration plants. The cleaned and separated metal fractions are sold around the globe to primary and secondary smelters, refineries, foundries and mills.

The Danish company gets all its sorting solutions for non-ferrous metals from STEINERT. The owner, Ejvind Pedersen, likes the fact that this centralized method of procurement saves time, allowing him to concentrate on developing innovative recycling ideas. Pedersen compares the efficiency and reliability of STEINERT with that of German automotive manufacturers. He stresses the confidence that his production staff has in the equipment and how easy the technical components are to operate.

Pedersen explains: “We produce four truckloads of aluminum a day. What makes this so significant is that industry doesn’t then have to be supplied directly from primary mining and improves its environmental footprint by using high-quality secondary raw materials. This translates into CO2 savings of 90 %.”

Pedersen focuses on the production of high-grade aluminum. The process starts with the non-ferrous metals separator for recovering Zorba from the ash. The next step is separating the stainless steel using an induction sorting system. Thanks to x-ray transmission, the STEINERT XSS T EVO 5.0 produces very pure aluminum by sorting out heavy metals. The sorting equipment’s detection rates are so precise that it produces an aluminum purity of up to 99.8%; material that is always highly sought after on the market. This also allows the metal to be kept in circulation for long periods. Secondary raw materials with high levels of purity are needed for high-grade applications.

It’s about more than price alone

The Stena Recycling group of companies has a network of 178 recycling plants in Europe and employs more than 3500 people. Every year, Stena recycles over 6 million tons of complex waste materials. The Stena Nordic Recycling Center handles 500,000 tons of complex materials annually, saving 870,000 tons of emissions.

Jesper Fournaise, Outbound Sales Manager at Stena Recycling S/A, is responsible for the production and sale of aluminium. “We’re the green gods,” is how Fournaise describes his team. By this, he means that scrap is converted into recyclable material that’s fed back into the production cycle. When asked what has changed the most over the last few years, he says: “We used to ship our scrap to the Far East, where it was sorted by hand and we didn’t know what happened to the material. Advancements in technological sorting represent one of the greatest differences. Now, here in our own country, we’re able to use x-ray technology to meet maximum quality standards and to put the metal back into commercial use.”

According to Fournaise, for a long while it’s not just been about the sales price of a metal: “Our customers, the smelters, save CO2 by using secondary raw materials and sorting is one of the most important primary stages. Because we strive for qualities similar to those of primary aluminium, we opted for sorting technology from Steinert. Steinert simply delivers the exact values we need for copper, zinc, manganese and magnesium. We’ve conducted continuous tests and now we’ve found the right level of quality.”

High levels of reliability and availability

Stemin S.p.A., a specialist in aluminum recycling located close to Bergamo in northern Italy, has decided to use STEINERT sorting technology, especially for dry density separation by means of x-ray transmission (XRT) to ensure the maximum purity of its aluminum production. Every year, Stemin produces up to 70,000 tons of high-quality secondary aluminum. The sorted aluminum is ready for the furnace and is passed to the company’s own foundry for further processing.

Board member Olivo Foglieni has been using STEINERT equipment for years and was one of the first to deploy the latest evolutionary stage 5.0 STEINERT XSS T. He is full of praise when it comes to the reliability of the technology and team: “I’m sure I don’t have to explain how important absolute reliability of the x-ray unit and sorting quality is for us. Both are indispensable to ensuring a smooth process between sorting and further use of the aluminum product. Downtimes put the entire supply chain at risk. But our long-standing experience with Steinert proves that this is something we don’t need to worry about.”

Stemin has replaced a total of four machines from competitors with STEINERT x-ray sorting technology in recent years. “Compared with the others, the biggest difference is how reliable the machines are. We have opted for Steinert because of their ongoing research and development in the field of metal recycling, the fact that the quality of their sorting is improving all the time, and because their more capable sorting systems help us to produce the quality levels we need. Each type of scrap that we work with has its own requirements and it is important for us to separate by input material, magnesium or heavy metals like copper. This is the challenge we face – and always with the goal of increasing the value of the metal,” adds Foglieni.

LIBS for even greater purity

As an extra stage, some of STEINERT’s customers use downstream LIBS sorting. Laser Induced Breakdown Spectroscopy (LIBS) can analyze, in real-time, the aluminum content and components, such as copper, magnesium or silicon, which determine the type of aluminum alloy. This process allows various alloys to be classified effectively, enabling the product to be used directly in producing industry. Recovery of targeted alloy compositions reduces downcycling.

STEINERT LIBS sorting systems have been widely distributed on the market for a number of years and more will be deployed in 2023. AMAG Austria Metall AG is a pioneer in sorting aluminum alloys and has been using one such system to sort into various aluminum alloy qualities since 2019. AMAG produces high-grade primary, cast and rolled products out of aluminum.

Demand for recycled aluminum is growing all the time. Separating into alloys is both an opportunity and a challenge. By producing pure aluminum alloy qualities from recycled aluminum, the specific reuse can be significantly improved. This is the route to closed material recycling.

AMAG has opted for LIBS technology from Steinert for this very purpose. An STEINERT LSS line sorting system produces up to 6 products in one cycle.