The Masotina S.p.A. plant in Milan, Italy, is a household waste plastic recovery and sorting facility with a total capacity of 355.000 tons per year. The facility has been retrofitted in recent years to include the most sophisticated recycling automation technologies to separate out recyclable waste plastics.

Italian waste management company Masotina’s S.p.A. facility is one of the largest material recovery facilities (MRF) in Europe that receives, sorts, separates, and prepares recyclable household waste plastics. Masotina has made substantial investments in recent years into advanced automation and recycling technologies to gain a leadership position in the plastic waste recovery and recycling market. By partnering with ZenRobotics, Masotina expands its technology leadership to include AI-based waste sorting robotics at its flagship facility.

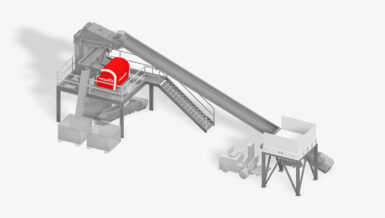

The robustly automated Masotina S.p.A. household waste plastic sorting facility is located near Milan and has a yearly capacity of 250.000 tons. The facility has been retrofitted in recent years to feature automated sorting and selection lines that make use of the highest recycling technology to separate out recyclable waste plastics through a combination of optical, mechanical, and manual sorting. One of the latest additions is the ZenRobotics Fast Picker sorting station that performs quality control at the facility, improving efficiency and reducing the need for manual sorting.

The facility separates household waste plastics coming mostly from the municipal collection. Plastic waste is first sorted from other valuable recyclable materials like paper, cardboard, aluminum, tinfoil, polylaminates, and inert. Then it is separated by polymer and color to maximize the recycle-reuse value of plastic. The job of the ZenRobotics Fast Picker is to ensure high output purity for clear PET by removing contaminants and taking out other valuable recyclable polymers such as HDPE that are returned back to the recycling loop. Thanks to its compact size, the ZenRobotics Fast Picker has been integrated into the existing sorting line despite very tight spaces at the facility.

ZenRobotics is excited to partner with Masotina, one of Italy’s strongest waste management companies. We were pleased to see that our robotics technology matches the rigorous sorting ambitions of Masotina. We strongly believe that smart robotics has enormous potential to recover more and more recyclable materials. The Masotina S.p.A facility is a perfect example of how existing MRFs can make use of the latest technology to improve their efficiency and economics in waste sorting, says ZenRobotics CEO Jarmo Ruohonen.

Italy is at the top of the major European economies in many sectors of the circular economy. The country has a strong plastic sector for both virgin and recycled plastic.