This more efficient management is a real need for Europe, since, according to Eurostat, in 2020 each European produced 505 kilos of waste, 38 more than in 1995. For this reason, European countries have been working for some time to increase waste recycling and improve the sustainability of the sector. A transformation of waste management that involves a greater use of digital technologies.

IOT for waste collection

The first of these phases, the collection, has a great technological ally: the Internet of Things (IoT). The combination of sensors, software and other technologies allows monitoring, collecting and analyzing data in real time and help, in this way, to optimize waste collection, significantly reducing its inefficiencies, is what is known as Green IoT. Among the solutions enabled by the IoT are, for example, the autonomous collection of waste or the existence of intelligent containers, while the latest innovations can be found within the technological field of drones or robots for underwater cleaning.

Two examples of the most innovative projects that add Deep Tech or drone technology to a first layer of IoT to enhance the sustainable solution would be: SeaClear, a European project that aims to automate the process of searching, identifying and collecting marine litter through autonomous robots that work collaboratively; or the Spanish project with drones Oriented to the control of illegal dumping and garbage deposits outside the indicated places.

Artificial vision, artificial intelligence and robotics for waste sorting

Artificial vision and artificial intelligence, often supported by robotic classifiers, are capable of generating information about the selected materials. These technologies are rapidly spreading across Europe with the aim of speeding up waste sorting and dramatically improving the accuracy with which waste is selected for further treatment and recovery. These technologies aim to make the second phase of the waste management process, sorting, automatable easier, faster and safer, for example by reducing human exposure to potentially hazardous waste streams and working with waste from all sectors, from food to pharmaceuticals.

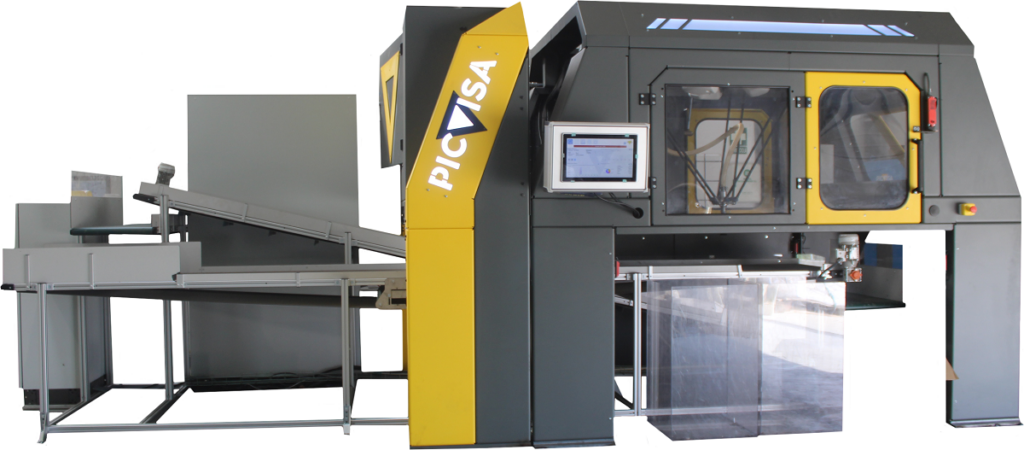

Responding to the needs of multiple sectors, PICVISA develops technological solutions based on artificial intelligence, artificial vision and machine learning, such as optical separators ECOSORT (textile), ECOPACK (polymers, paper, cardboard and textiles) and ECOGLASS (glass). These optical separators make it possible to classify and recover different types of waste. The combination of these optical separators with robotic solutions such as ECOPICK, which incorporates artificial intelligence, increases sorting speed, minimizes errors and improves process efficiency.

A good example of this is the project presented last October and that connects PICVISA with the Generalitat Valenciana and the multinational Nestlé. The collaboration agreement includes the installation of an ECOPICK artificial intelligence robot from PICVISA in the Picassent light packaging selection plant near Valencia. The objective of this initiative is to separate and classify small plastics as coffee capsules, plastic caps and yogurt containers that otherwise would have ended in the landfills.

Big data and blockchain for waste treatment

Efficient management is key to reducing the number of landfills, minimizing CO2 emissions, saving water and energy, reducing the extraction of raw materials, and creating sustainable employment, among other benefits.

At this point the data is key. The digitalization of the sector will also allow waste management to be 100% monitored and integrated with industry 4.0 and use Big Data to have solutions that increase control, efficiency and profits, optimizing all stages of the process. If we add to this the incorporation of cutting-edge technologies such as Blockchain, the result is an almost total monitoring of the waste treatment process along with the traceability of the waste itself.

This is where PICVISA adds its ECOFLOW and DATA+ technologies, a flow analyzer that allows image collection, data processing and visualization to analyze the flow of the recycling plant (ECOFLOW) while providing the platform that shows the information of the plant activity. In this way, all the information can be displayed remotely accurately and in real time.

As we can see, innovation within the three stages of waste management are the short and medium term future of the sector and is the only way to achieve the ambitious objectives the EU has set for reducing waste and increase the circularity of materials. PICVISA’s technology is in a mission to achieve that.