AIK Technik – the specialist for the optimization of waste incineration plants

When it comes to process optimization in the field of fly ash treatment, mercury and dioxin separation in flue gas purification or wastewater treatment of waste incineration plants and the development of plants, components and processes, AIK Technik AG from Sursee, Switzerland is regarded as a proven partner for authorities, special-purpose associations and various branches of industry in the private sector. The innovative company services 26 of 30 waste incineration plants in Switzerland and many more abroad.

As an experienced plant constructor and specialist for sustainable resource utilization, AIK Technik AG supports its customers in using innovative processes to close interrupted material cycles again and to achieve long-term and sustainable added value for the economy, energy and the environment with its plants. In doing so, AIK Technik preferably uses the following processes:

Recovery of recyclable materials after slag processing

The incineration process produces slag, which contains solid rock-like material as well as ferrous and non-ferrous metals. The slag is processed – iron scrap as well as elemental aluminum, copper and brass are separated and collected. After recovery of these valuable materials, the remaining residual slag can be stably landfilled.

Removing mercury from wastewater

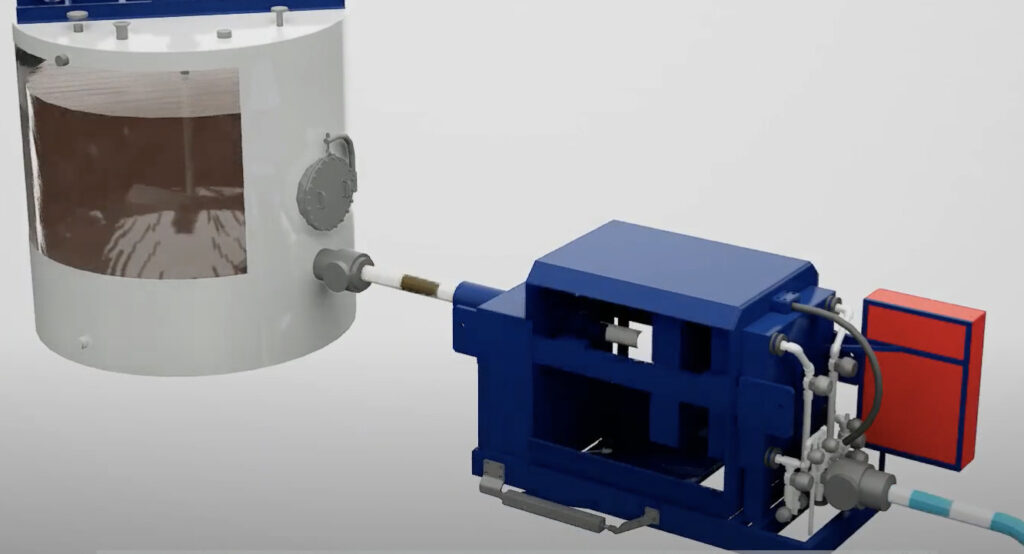

The process water to be treated from flue gas cleaning contains mercury, which is removed from the system in the first process stage. The process is based on two stages: prefiltration of the scrubber wastewater and mercury removal via selective ion exchange columns. The process removes approx. 98% of the mercury introduced into the wastewater incinerator, thus falling well below the limit values in the wastewater – an environmentally sound process that is widely used in various industries.

Heavy metal recovery/recycling with filter and fly ash washing (FLUWA by AIK®)

Acidic filter and fly ash washing (FLUWA by AIK®) forms the core of AIK systems. Zinc, copper, cadmium, lead and other metals are efficiently removed from the filter and fly ash in the extraction process after mercury separation in the acidic wash effluent or liquid waste discharge. Currently, this FLUWA process treats more than 50% of the filter ash load generated throughout Switzerland. According to the motto “recovery before landfill”, the FLUWA process enables recycling of heavy metals and transforms the fly ash from hazardous waste to be compulsorily exported to residual material to be disposed of normally. The FLUREC process co-developed by AIK Technik in Sursee, Switzerland, is also available to efficiently recover heavy metals.

Heavy metal-free wastewater thanks to wastewater treatment (ABA)

The incineration of waste produces flue gases that must be cleaned. Wet flue gas cleaning, which has the best cleaning effect, produces wastewater that must be cleaned. Afterwards, the wastewater can be returned directly to the environment or sent to a public wastewater treatment plant. One of the goals of cleaning wastewater from waste incineration plants is to separate the heavy metals it contains and return them to the circular economy. This is done in the wastewater treatment plant of AIK Technik AG. The residual separation of the heavy metals is carried out by downstream selective ion exchangers. All requirements of the Swiss Water Protection Ordinance are met.

Phosphorus recovery with Leachphos© process

With the Leachphos© process, phosphorus can be recovered from municipal sewage sludge ash according to the principle of closed-loop recycling. The phosphorus recovered in the recycling process is processed into fertilizer or phosphoric acid in a further stage. Both substances comply with the environmental requirements of the Fertilizer Act.