As rising numbers of people switch to reusable containers, such as drinks flasks for hot and cold drinks and as others make the move from plastic bottles to metal cans. People started to realize that recycling more metal can make a real difference.

For example: aluminium drinks cans are part of a closed loop recycling system. As long as they are placed in the recycling, they can be back in the shops as a new can in as little as 60 days.

As a 100% recyclable material, the recycling of metal has always been a top research and development priority for Keson and has been listed as one of its 12 categories.

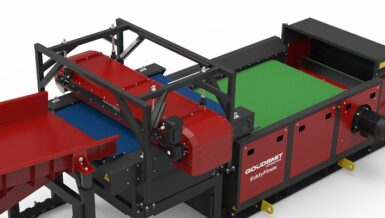

Keson’s self-developed scrap metal intelligent treatment system can efficiently sort ferrous metals, non-ferrous metals, waste plastics and other recyclable materials through dismantling, shredding, screening, air separation, magnetic separation, AI separation, optical separation and color separation technologies. After remelting in the furnace, scrap aluminum can be cast into recycled aluminum ingots, scrap iron can be cast into iron ingots, and waste plastics can be made into plastic alloy products, which greatly reduces environmental pollution and enhances resource recovery.

In many areas of circular economy, Keson has outstanding R&D strength and ranks among the best in the industry. Contact Keson to see how we can help you address the gap between solution supply and the fast-rising demand for solid waste with the latest technology.