The line has an initial capacity of 1.5 metric tons/hour (3,300 lbs/hr) output of flakes. It incorporates a modular design where the output can be increased to 2.5 metric tons/hour (5,500 lbs/hr) in the future.

In addition to PET, HDPE and PP are also recovered to be sold into the recycled material markets.

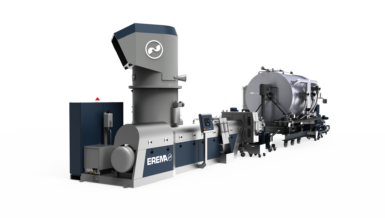

The line consists of machinery and equipment manufactured by STF Group in Germany. The sorting line includes Material Feeding and Conveying Systems, Bale Braker, Dosing Screws, Magnetic Over-Belt Metal Separator, Manual Sorting Station, Label Scraper, and Star Screen. The line also features wide Tomra AutoSort optical bottle sorters with two parallel streams.

The washing equipment includes STF Wet Grinder with Friction Cleaner and Circulation System, Air Stream Separation, Hot-Washers, Sink/Float Separation Stage with Stirring and Separating Containers, Post-Washers, Tomra Flake Sorting, Filling Stations for PET, PO and Labels as well as a Water Treatment System with Decanter, Neutralization Tank and Dosing Station.

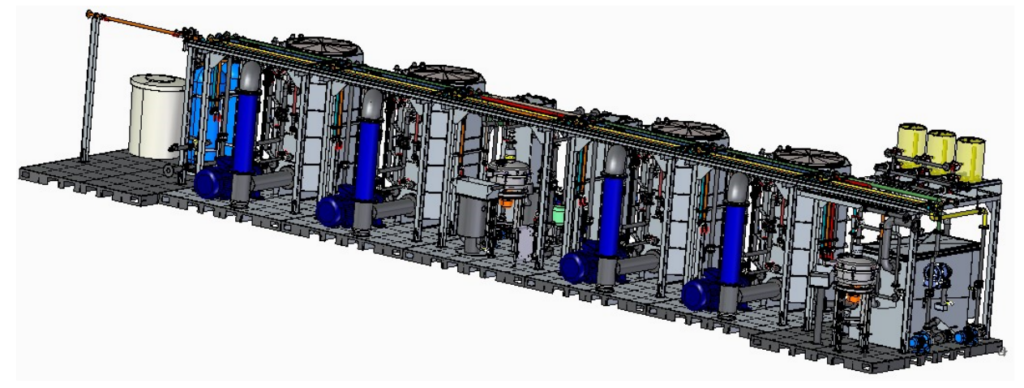

Along with the Recycling Plant, a Zero Liquid Discharge System (ZLD) will be installed. The system offers complete circular Waste Water Recycling with 100% of the water recirculating back into the wash line after filtering out all impurities.

Absolutely no waste water will be discharged into the sewer system. All waste water will be cleaned, re-circulated and re-used. The ZLD allows for minimal fresh water usage, only about 1% of conventional plastic wash lines. The ZLD creates substantial savings for the operation and underlines the company’s commitment to sustainability.

Installation of the line will begin in the second quarter of 2024