With a better understanding of waste management, municipalities and state governments are establishing local processing centers for community and commercial drop-offs, instead of directing the public and garbage pickup contractors to offload at a landfill. These smaller facilities are closer to residential neighborhoods and need a detailed dust and odor management plan. Environmental engineers designing these plans are increasingly using atomized mist technology to cut airborne particulates and effectively spread odor-neutralizing chemicals.

Causes of Dust in Indoor Waste and Recycling Facilities

Whether it is a garbage truck with MSW, C&D drop-off, or a private citizen emptying their pickup truck, off-loading can emit excessive dust. Other dust-generating activities at waste terminals include disruption from front loaders as they sort material on the tipping floor, backdraft from dropping material through subfloors, or emissions from loading waste onto other transport vehicles.

Indoor recycling dust can affect workers during their shifts. Separating small materials often requires vibration screening, which can produce plumes of particles. However, that process is automated. At some point, workers need to stand at a conveyor and manually separate materials. Although PPE helps protect them, worker morale and workplace conditions are significantly improved when dust is controlled with atomized mist technology.

Indoor Dust Regulations

Although the air can look clean, regulated dust emissions are invisible to the naked eye, and the smaller they are, the more dangerous they become. Regulations aim to protect not only workers but also the general public. Fitting workers with proper personal protective equipment (PPE) can be effective but does not fully cover contractors and private citizens who also use the facility.

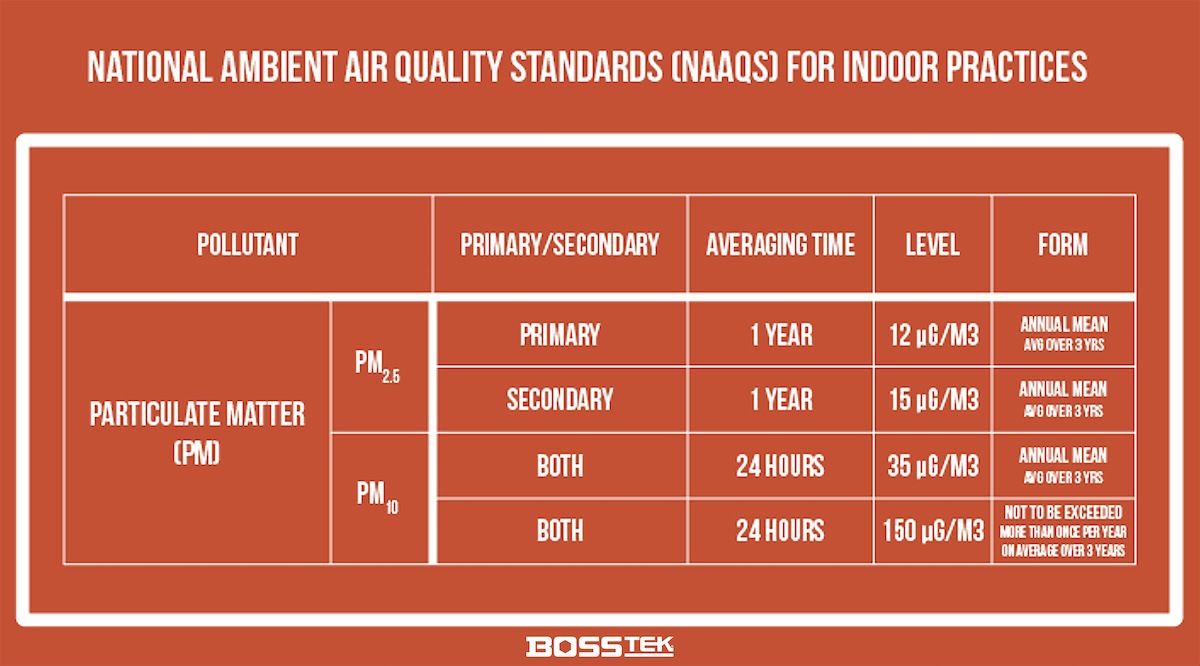

Complaints about dust and odor can prompt an OSHA or EPA inspection (or both). Investigators measure dust size by microns (µm) and volume in micrograms (µg) using personal detection devices worn by workers throughout a shift. Lightweight particulate matter (PM) as large as 200 µm – roughly the size of a small grain of sand — can remain airborne on normal ambient air currents. Particulates are no longer visible to the naked eye under 100 µm. At the size of <PM10 (the indoor air quality IAQ regulated size threshold for most airborne particles), the tiny particles avoid the body’s natural defenses and penetrate deep into the lungs. [1] The human health effects of excessive PM exposure are well-established and are used to set the National Ambient Air Quality Standards (NAAQS).[2]

a general benchmark for workplaces in the U.S.

How Do Mist Cannons Work?

An automated indoor misting cannon has a high-powered fan at the back of a cone-shaped barrel. Mounted on the front (exit side) of the barrel is a ring manifold with multiple nozzles that fracture pressurized water into microdroplets roughly the same size as the airborne dust. The fan creates a powerful air stream that is concentrated in the barrel, directing the air at a high velocity out the front. The forced air carries millions of microdroplets and distributes them in a dust suppressive plume wherever the cannon is pointed.

The standard indoor unit features 30 brass nozzles, which can also be specified in stainless steel or nylon. The high-efficiency, three-phase direct-drive fan motor delivers 9,200 CFM of air flow (260.5 CMM), while the optional single-phase motor provides 8,000 CFM (226.5 CMM).

With a coverage area of more than 6,100 square feet (566 square meters), the standard cannon configuration produces a throw of more than 100 feet (30 meters) while using only 4.9 – 9.8 GPM (18.5 – 37.1 LPM) of water. Although most terminals are designed to control wastewater runoff, unlike hoses and sprinklers which use more than 75 GPM to operate, the atomized mist spreads out to minimize pooling and runoff.

Indoor misting cannons can be placed in specific locations throughout the operation and controlled remotely. The units are automated, so after being turned on, workers can leave to perform other tasks. This helps cut labor costs by reducing the need to hold hoses and decreasing worker exposure to hazardous IAQ at the emission point.

How is Atomized Mist Effective?

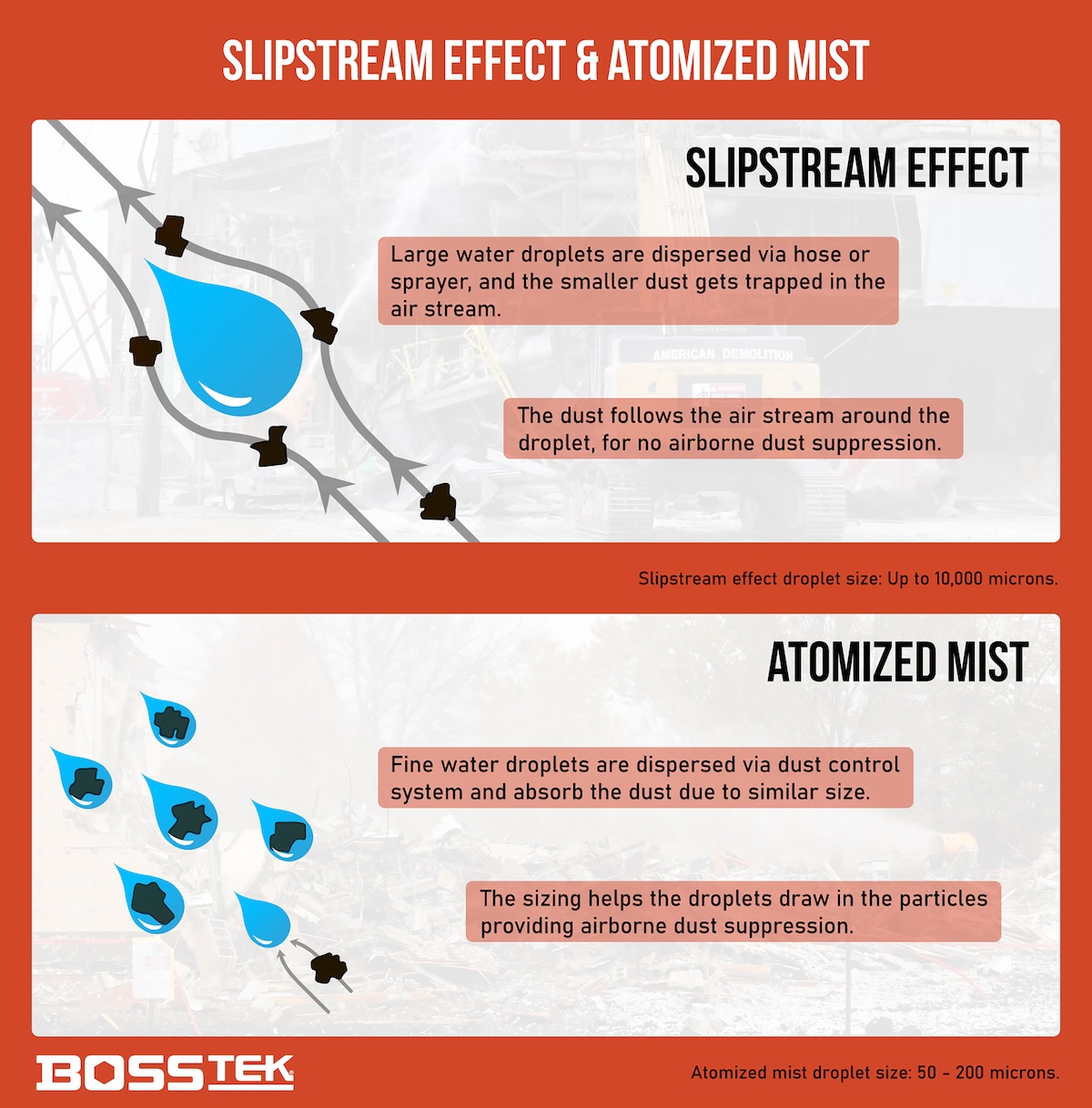

To be effective, droplet sizes need to be roughly the same size as the airborne particulates. Hoses and sprinklers are not appropriate for indoor applications, since they create droplets between 200µm and 1000µm. These would saturate the area, creating pooling, which introduces slip and fall hazards, another common OSHA violation.

Droplet sizes greater than 200µm don’t offer airborne dust suppression due to the slipstream effect. Atomized mist, on the other hand, produces droplets in the range of 15µm to 200µm, small enough to collide with airborne particulates and pull them to the ground. There is little to no pooling and with proper indoor ventilation, the droplets follow the dust and absorb the particulates before they spread.

Controlling Odor

To control odor, the misting cannon can be fitted with a dosing pump for chemical additives. The pump can deliver a range of volumes from a minimum of .003 GPH (.009 LPH) to a maximum of 2.5 GPH (9.5 LPH).

Deodorizers have been found to be an effective control for the majority of industrial odor emissions, treating the smell on a molecular level. These chemicals work by replacing the odor-causing element in the structure of the odor molecule with an inert element. This makes the mist delivery system effective because the miniscule droplets have a great chance of interacting with the molecules in the air, especially if they’re attached to a particulate.

When Workplace Safety is Public Safety

Whether the facility is open to the public or not, dust and odor emissions impact the community in various ways. Workers exposed to poor air quality may be prone to illnesses, including respiratory problems and bacterial infections. Although research on the adverse health effects of living and working near waste management sites is still in the early stages, large-scale studies conducted by the National Institutes of Health in recent years have shown that local communities and workers can experience illness, lower birth rates, and higher mortality.[3] Researchers have called for further studies to better understand these initial findings and to guide future regulatory policies.

Negative public perceptions of a local facility can seriously affect operations. Aside from complaints to government agencies like OSHA and the local EPA, there may be political consequences impacting permits and funding. Effective and visible dust and odor control can greatly influence how the operations are viewed and can significantly improve the workplace environment. The return on investment for a dust and odor management plan that includes atomized dust technology is fairly quick once you consider reduced labor for dust control, improved morale, and fewer sick days.

Resources

[1] U.S. Occupational Safety and Health Administration; Indoor Air Quality. U.S. Department of Labor, Indoor Air Quality in Commercial and Institutional Buildings. OSHA Publication 3430, (2011)https://www.osha.gov/sites/default/files/publications/3430indoor-air-quality-sm.pdf

[2] U.S. Environmental Protection Agency; NAAQS Table. National Ambient Air Quality Standards (40 CFR part 50)https://www.epa.gov/criteria-air-pollutants/naaqs-table

[3] Vinti, Giovanni; Bauza, Valerie, et al; Municipal Solid Waste Management and Adverse Health Outcomes: A Systematic Review. National Institutes of Health, Int J Environ Res Public Health. 2021 Apr; 18(8): 4331. Published online 2021 Apr 19. doi: 10.3390/ijerph18084331