The majority of aluminium scrap processed by INTALS originates from across Europe, primarily from Germany, Austria and Switzerland, but also from the Middle East, America and Australia. INTALS covers the entire spectrum of aluminium products: Profiles, turnings, castings and more complex materials such as Zorba and mixed scrap. ‘Our entire production process is based on the use of aluminium scrap, which is not only more sustainable, but also ensures that we minimise the environmental footprint of our products,’ says Alessandro Colla.

Clean secondary resources for the mobility of the future

INTALS primarily supplies the automotive industry, where demand for ingots made from recycled aluminium is high. With the increasing demand for electric and hybrid vehicles, the requirements for raw materials are also changing. The challenge is to produce aluminium with fewer impurities and a lower copper and zinc content,’ explains Colla. ‘Thanks to STEINERT’s state-of-the-art sorting technologies, we are in a position to meet these requirements.’

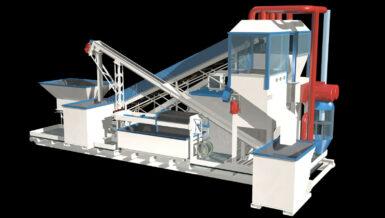

As part of its ongoing development, INTALS has installed four state-of-the-art STEINERT XSS T sorting systems with X-ray transmission technology. These machines separate metals based on their density. ‘The XSS T systems from STEINERT have proven to be a fundamental part of our production,’ reports Colla. ‘They enable us to separate aluminium scrap precisely and consistently and allow us to manufacture products that are practically free of impurities. This has not only opened up new markets for us, but also increased our competitiveness on a global level.’

In addition to technological innovation, INTALS is also heavily involved in the industry’s sustainability efforts. ‘Sustainability plays a key role in the aluminium industry,’ emphasises Colla. ‘Without recycling, sustainable production would not be possible. Our entire production is based on producing aluminium with minimal CO₂ emissions.’ This is particularly important for the automotive industry, as manufacturers are increasingly demanding environmentally friendly materials in order to reduce their own CO₂ emissions.

The future demands even deeper sorting

Future-oriented is also the introduction of the new LIBS technology (Laser Induced Breakdown Spectroscopy). After initial reports on the brand new STEINERT PLASMAX | LIBS, Colla was impressed by its potential. ‘LIBS will enable us to sort aluminium alloys from the 1000 to 8000 series even more precisely and thus meet the requirements of car manufacturers,’ he says. Tests have shown that even the smallest amounts of impurities can be recognised and eliminated, which makes the production of high-purity alloys much easier. Alessandro Colla was impressed not only by the capabilities of the STEINERT systems, but also by the expertise of the STEINERT technicians. He said, ‘Before purchasing the STEINERT XSS T systems, we conducted extensive tests with a highly qualified team that demonstrated the full potential of the machines. In collaboration with the STEINERT technicians, we developed effective solutions to successfully overcome the challenges we were facing. ‘

A sustainable collaboration for sustainable products

To summarise, the partnership between INTALS and STEINERT is a prime example of the successful combination of recycling, cutting-edge technology and market requirements. Colla sums up: ‘Without STEINERT’s reliable sorting systems, we would not be able to produce the quality from scrap that the automotive industry demands. These machines are a crucial part of our strategy for the future.’