This law amongst other issues, addresses postconsumer textile as a residue that has to be collected selectively from household. This new situation will mark a before and after for this industry that, since 2017, surpasses plastic in weight in tons of produced waste.

Today the practise of burning clothes has become increasingly common for some of the world’s biggest clothing manufacturers. Why? They argue it is the most cost-effective way of maintaining their brand’s exclusivity.

With this new regulation, manufacturers will not be able to destroy unsold garments and will have to pay to recycle their waste. A process that will be very similar to what is done today with packaging containers. These restrictions will require the creation of a circuit of collection and selection of materials for subsequent recycling and it is here that the possibilities offered by technology to help in the recycling schemes of textile material can arouse an increasing interest.

Recyclability

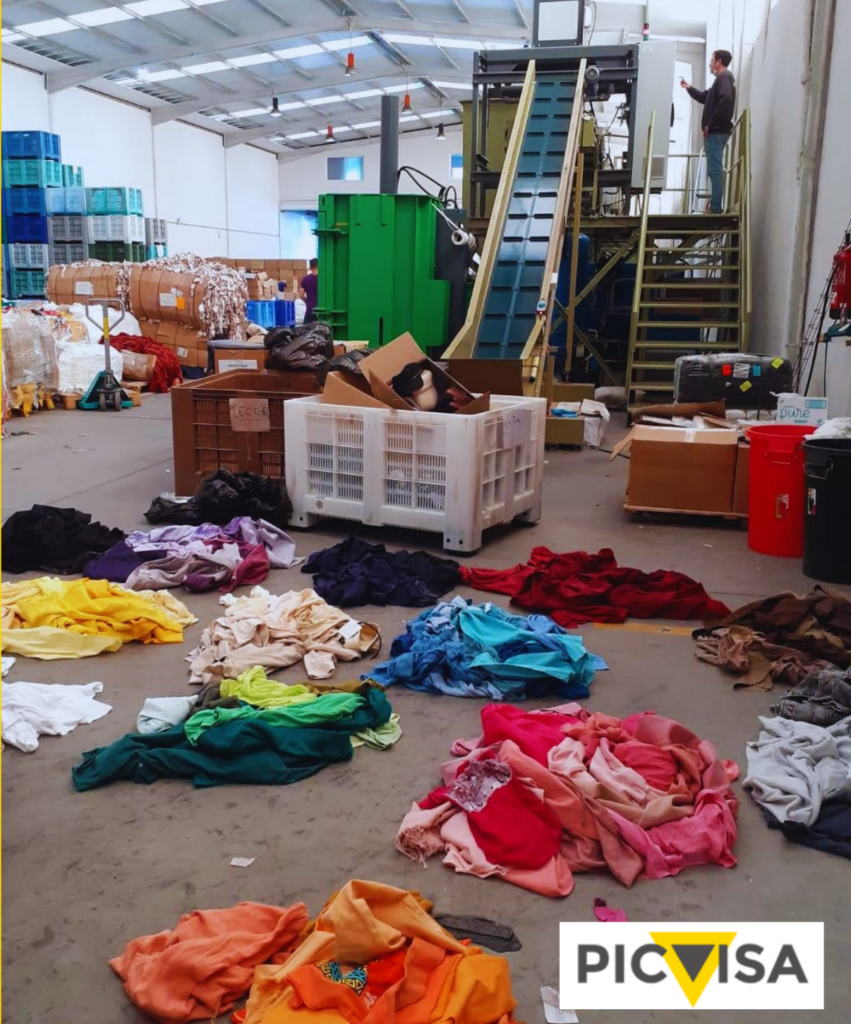

The recyclability of textile materials presents a great complexity, comparable to that of plastics. The great variety of materials, confections and colors that are used for its manufacture make it difficult to subsequently recycle.

In addition, being articles linked to fashion, they present multiple shapes and elements that are constantly changing and contain a wide variety of accessories that hinder their recyclability in an automated way.

The first step towards recyclability is inevitably to optimize the processes of classification and separation of the different textile waste by composition and color, as is already done with plastics. And is here where technologies like the ones we develop at PICVISA can arouse a growing interest to the field.

Where does the textile waste come from?

Let’s take for example the figures of textile waste in a country as Spain.

Even though data is uncertain because of lack of rigorous information, it is estimated that each year about 1,050,000 tons of textile waste are generated, of which 50,000 would be pre-consumer (generated by textile manufacturers), 900,000 tons of post-consumption that would end up in landfills and about 90,000 tons per year would end up in containers for subsequent recycling and reuse.

As we see in these figures a large part of the textile is domestic waste. Currently this material is collected in a very small part via associations and companies that have a container in certain locations (Caritas, Humana, Solidanca etc) but the vast majority of this material ends up in the container of MSW of our cities.

Closing the loop

Textiles entering Europe’s MSW plants largely end up in a landfill or incinerated and they are also a big operational problem in waste plants since they generate many problems in the maintenance of equipment.

PICVISA presents two solutions for this material in MSW plants:

– ECOPICK: Robotic solution for the extraction of textile materials from the MSW flow. This solution is designed to be installed in primary sorting cabins, thus avoiding the large maintenance costs caused by textile.

– ECOPACK: Conventional optical separator equipped with NIR and AI for the identification and separation of textiles.

In the case of pre-consumer textiles and post-consumer collected selectively, the material is in relatively good condition and already separated from other waste. These flows end up in triage plants where textile garments must be classified by type of material and color.

PICVISA equipment integrates NIR and AI technologies which allows the classification by material and color of up to 24 different types of combinations. The 24 outputs can be configured at the customer’s need depending on their input product. PICVISA’s sorting solutions are designed to be integrated into the current lines that still require a rework of the material, either before the optical classification or after, it also allows to work with the garments without having to pre-crush the material previously.

Clothing consumption is expected to increase globally by 63% by 2030, from 62 million tons today to 102 million tons by 2030, which will put unprecedented pressure on the planet. Currently, 73% of garments globally end up in landfills.

In this scheme, our technology can play a key role in making the goal of reducing textile waste set by the European Union for 2025 a reality and, in this way, significantly reduce the environmental impact of the textile industry.

Visit us at IFAT Munich 2022, May 30th-June 2nd: Hall B6 Booth 301