Then the MopaLIBS system from SECOPTA analytics GmbH is the right choice for you. It classifies scrap into any number of material classes quickly and with maximum precision in accordance with the alloy composition.

What is LIBS?

Laser-induced breakdown spectroscopy (LIBS) is an atomic emission spectroscopic method, where a short-pulsed laser is focused on the sample surface. The high-power density of the laser interacts with a small amount of the sample surface and leads to material removal and plasma formation. The plasma emits characteristic light depending on the elemental composition of the sample. LIBS is a contact-free method and provides a multi-element analysis in milliseconds with no sample preparation.

How does the MopaLIBS work?

By using a distance sensor based on the laser triangulation, the surface of the scrap is continuously scanned and a height profile of the scraps is created. With the known sample height profile an optimal laser alignment on the sample surface is assured which provides good spectral data and allows to quantify of even minor components. The range of the dynamic focusing is about 140 mm and allows a precise analysis of a wide variety of sizes and shapes of scraps. The combination of a pre-ablation laser and a LIBS laser allows even the analysis of lacquered, oxidized, or otherwise contaminated material with high precision. Therefore, the pre-ablation laser digs a trail of a few micrometers in the material, and afterward, the LIBS laser is used for the material analysis. Depending on the determined elemental concentrations the scraps a sorted into different classes. The sorting criteria are customized and can be easily adjusted by the customer. The MopaLIBS works at conveyer belt speeds up to 3 m/s and provides high throughput. Regardless of whether you want to sort aluminum, stainless steel, or other materials according to type, with the MopaLIBS system you have a powerful tool at your side.

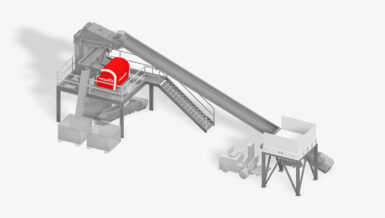

High-speed LIBS-based sorting of aluminum scraps on a conveyer belt in e.g. 1.xxx–7.xxx fractions with the MopaLIBS system. The distance sensor allows a dynamic focusing of the lasers in respect of the sample height and shape. Before analyzing the material with the LIBS laser, a cleaning step with the pre-ablation laser is applied.

Cleaning step of the sample surface with a pre-ablation laser and the analysis of the clean material with a LIBS laser.

All in all the Mopa-LIBS system provides:

- Qualitative and quantitative analysis

- Customized material class assignment

- Industrial-suited enclosure (IP65) and customized communication interface