Why should plastic recycling include segregating and recycling of moisture?

First of all, less moisture equals less weight and thus less additional heating and transportation and gate fee costs. Secondly, moisture is a valuable resource. It, therefore, can be sustainably reused in your production process or be turned into clean water.

Optimized value of dry plastics

That is not all. Through the extraction of the liquids, the solid material gains more value too. In the case of paper pulp rejects, the calorific value of the remaining dry fraction optimizes, and less additional heating is required while turning the rejects into alternative fuel.

Unique high-pressure waste separation technology

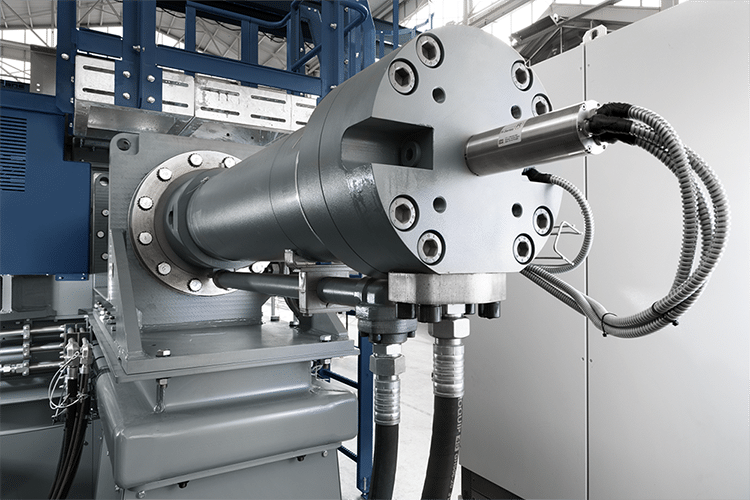

Commonly used dewatering technologies, such as screw presses, generally show moderate drying results. Often, 40 to 60% of the moisture remains after pressing. The Royal Dutch Kusters Engineering Organic Liquefying Press (OLP) separates moisture from solid waste fractions in a smart and energy-efficient way. It can reach a 25 to 80% weight reduction in moisture.

To extract the liquid fraction, the material is pressed through a sieve using hydraulic pressure. By reaching a higher pressure per cm2 then conventional technologies, the OLP can deliver a more constant quality of purity for both the dry solid and liquid fraction. Which, in turn, can be recycled or turned into energy more sustainable and efficient.

For more details on e.g. footprint, please download our brochure.

Royal Dutch Kusters Engineering is a family-owned company with a proven history of innovation and entrepreneurship. In the past 109 years, we build extensive knowledge about separating, reducing, pressing and transporting all types of waste.

If you want to know more about our way of working and how we can add value to your business, please do not hesitate to contact us.