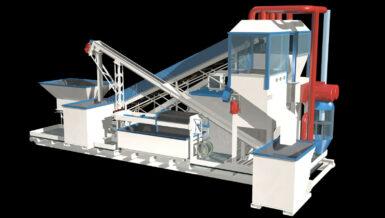

The two new Starlinger recoSTAR PET 165 HC iV+ recycling lines are set up at the recycling facility of Ganesha Ecopet Private Ltd. in Warangal, Telangana State. The company, a subsidiary of Indian PET recycling pioneer Ganesha Ecosphere Ltd., already produces recycled PET flakes and pellets for food-grade packaging as well as for filament yarns and fibres on two Starlinger lines installed in 2022. The new recycling lines are in operation since mid-2024 and triple Ganesha Ecopet’s annual production of bottle-grade rPET, raising it from 14,000 tons to a total of 42,000 tons.

EPR and consumers drive demand for sustainable products

The increasing demand for food-safe recycled PET in India has two main reasons. On the one hand, the Indian government has introduced Extended Producer Responsibility (EPR) for importers, brand owners and plastic waste processors as part of its Plastic Waste Management (Amendment) Rules in 2022 to ensure systematic collection of plastic waste. In addition, the rules stipulate that brand owners and producers must include a 30 % share of post-consumer recycled content in PET bottles by 2025, with the share being gradually increased each year to reach 60 % by 2029.

On the other hand, consumer preferences in India are changing, with sustainability being one of the top five factors for purchasing a product. Especially the large number of young consumers —i.e. millennials and generation Z— are increasingly demanding products and packaging that do not harm our planet. Brands respond to that by creating supply chains and packaging that are circular and sustainable. Recycled PET is one of the most convincing options for plastic packaging, given its continuous recyclability and lower carbon footprint compared to other alternatives, while not compromising on production scale, durability or quality.

“Our goal is not only to recycle plastics, but to create premium-quality, sustainable and viable circular solutions for brands,” said Sharad Sharma, Managing Director at Ganesha Ecosphere. “Recycling is not just an environmentally responsible choice; it is a powerful way to reduce CO2 emissions and mitigate the effects of climate change. Starlinger’s superior food-grade PET recycling technology, combined with the operational expertise we have built up over the last 30 years on the Indian waste recycling market, enables us to push the boundaries of what is possible in PET recycling. Today, we proudly provide the best quality of recycled PET: like-to-like in properties with virgin PET, but with huge environmental savings in carbon emissions and energy. Various global FMCG brands like Coca-Cola have placed their trust in us to make their packaging circular while ensuring utmost safety and quality for the consumers.”

“Ganesha Ecosphere is one of the trailblazers for a circular plastics economy in India,” said Paul Niedl, Commercial Head of Starlinger recycling technology. “With their vast experience in the Indian plastics recycling sector and their willingness to invest in state-of-the-art technology they are able to transform post-consumer scrap into a high-quality secondary raw material for plastic packaging producers. As a technology developer and supplier, we are proud to support Ganesha Ecosphere on their way to ensure a clean, healthy and liveable future for our children.”

Focusing on sustainable production, Ganesha Ecopet also minimized the process-related carbon emissions by recycling and reusing 95 % of the consumed water as well as increasing the use of renewables in plant operations. With a total production capacity of 42,000 tons of food-grade recycled post-consumer PET per year the PET recycling company caters to Indian, US, and European markets. “We are grateful for the partnership with Starlinger and especially applaud their highly advanced, food-safe bottle-to-bottle recycling technology as well as their continuous support that has made this feat possible and circular economy a reality,” Sharad Sharma concluded.

Incentives for improving the Indian waste management sector

Ganesha Ecopet sources post-consumer PET bottles from every possible channel: online, offline, and through more than 300 suppliers and aggregators across India. The Indian government has set a focus on improving the waste management sector. Due to the size and efficiency of the already existing informal waste collection network, through which around 95 % of PET waste —one of the highest rates worldwide— in India is collected and recycled, the main goal is to optimize the current systems. There are various start-ups that are tackling multiple aspects, from piloting deposit return/refund schemes to online scrap marketplaces. The government also plays an important role by setting incentives for better Environmental, Social and Governance (ESG) practices and taxing unsustainable practices.

A pioneer in PET recycling

Ganesha Ecosphere looks back on more than 30 years of experience in the PET recycling business. Founded in 1987, the company started out as a yarn production facility. In 1994, it was among the first companies in India to reprocess PET waste to manufacture recycled polyester staple fibre (RPSF) and recycled polyester spun yarns (RPSY). By today, the group operates six production sites located in the Indian states of Uttar Pradesh, Uttarakhand and Telangana, and one in Nepal. In addition to bottle-grade rPET pellets and flakes, Ganesha Ecosphere produces rPET staple fibre for yarns, nonwovens, flame retardant fabrics, and fibre fillings. Its highest quality rPET products are produced by its subsidiary Ganesha Ecopet and marketed under the brand name “Go Rewise”. With over 2700 employees and exports to more than 18 countries, Ganesha Ecosphere ranks among the largest rpet producers in India, recycling 9.4 billion PET bottles per year.