Starlinger and its customers already received a total of 120 “Positive Opinions” under the previous Regulation EU 282/2008—more than any other manufacturer of PET recycling technologies. The positive assessment of the PET bottle-to-bottle recycling process on the “recoSTAR PET art” system is the first positive Scientific Opinion under Regulation EU 2022/1616 for Starlinger.

Under the new regulation, modified and stricter assessment criteria are applied: The permissible limits after decontamination for substances such as toluene, chlorobenzene and methyl salicylate, for example, have been reduced by up to 50 %. The corresponding challenge test showed that the recoSTAR PET art process clearly exceeded the required cleaning efficiencies.

As soon as the European Commission authorizes the decontamination process based on the positive Scientific Opinion (by allocating the officially registered Recycling Process Authorization Number RAN to the respective process), the process developer can license it directly to recyclers. This makes the authorisation procedure a lot easier and faster compared to before because once the process has been approved, no further tests are required.

Higher throughput, lower energy consumption

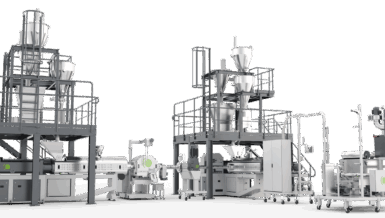

Starlinger presented the recoSTAR PET art PET bottle-to-bottle recycling system for the first time in 2022 at the “K” plastics trade fair in Düsseldorf as the successor to the well-known recoSTAR PET iV+ systems. The new machine model reduces energy consumption per kg by around 25 % while increasing throughput by 15 % and more. The machine range covers throughputs from 1,000 kg/h to 3,200 kg/h.

Starlinger customers worldwide supply around 2.5 million tons of food-grade PET regranulate for beverage bottle production per year. Almost 300,000 tons of this are already produced on 18 recoSTAR PET art systems which are in operation in Europe, America, Africa, India and Southeast Asia.