Getting to know the mine

This natural treasure of the European Union is located more than 4 kilometres deep in the highlands. The Gemerska Poloma mine has a deposit of 1.6 million tonnes of talc to date; however, experts estimate that there are still 15 million tonnes of the mineral lying deeper within the mountain. The modern technology employed in the mine and during the subsequent material processing makes it possible to produce more than 60,000 tons of high-purity white talc annually.

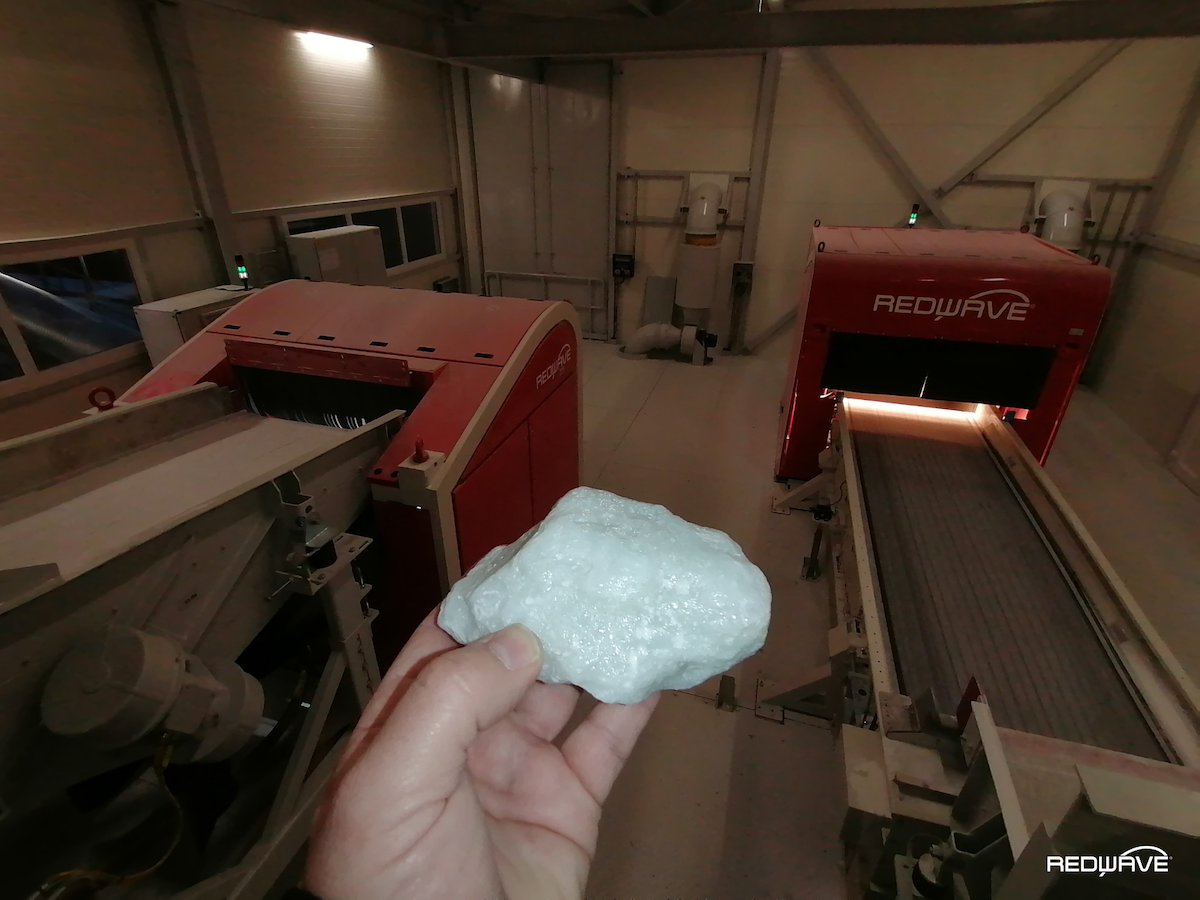

The talc in this deposit represents a part of a sizeable lenticular carbonate body with the main magnesite composition. This talc raw material deposit is considered one of the most modern mines. Expectedly, the quality and quantitative parameters are high, as the talc produced here reaches a degree of whiteness of over 90% and a purity of more than 97%.

State-of-the-art sorting technology

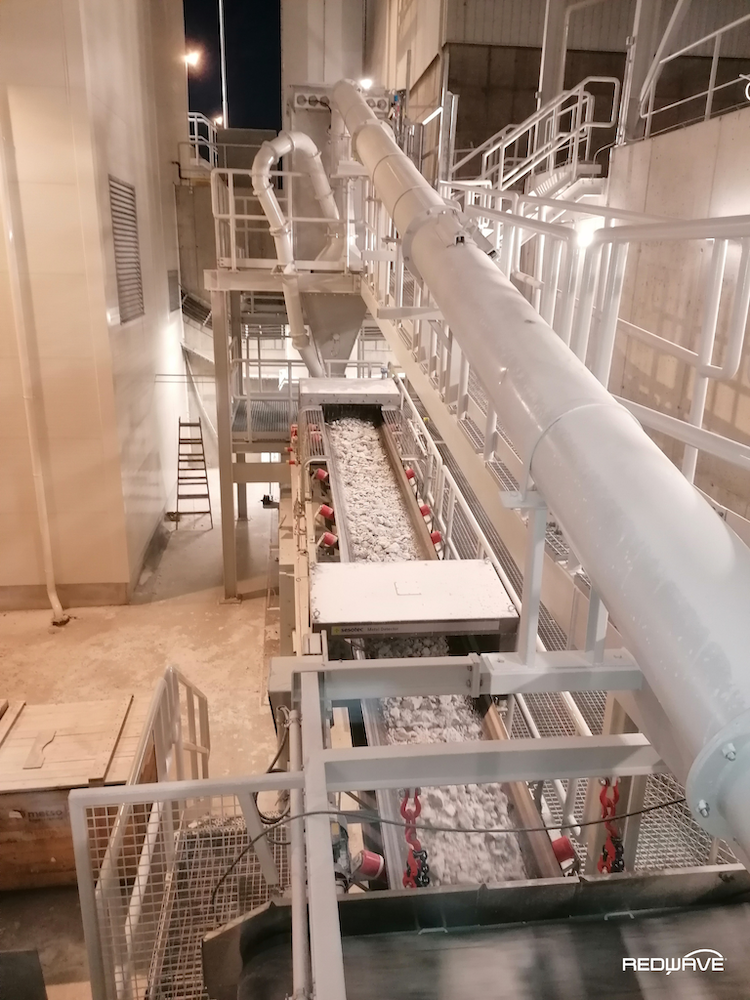

Professional processing is crucial to obtain minerals of the highest quality. In 2021, euroTalc started up successfully a new sorting plant built by REDWAVE / BTW Plant Solutions to further meet the increased demand for its already well-known top-quality talc.

REDWAVE was involved in the whole process, from the design, development, delivery and installation to the commissioning of the complete talc sorting plant. The entire system consists of crushing, screening, conveying, storage, washing and the sorting stages. The sorting is based on NIR-SSI and colour detection. Two REDWAVE machines were installed: REDWAVE ROX Belt sorter for the fine material and REDWAVE ROX Chute Sorter for the coarse material.

“The test with samples of our material at REDWAVE gave a good prospect for the project. The sorting results in operation of the new plant are topping that tests which is more than satisfactory. Due to Covid-19 restrictions during the erection of the plant we have to thank REDWAVE that we could keep the original time schedule and the plant was taken into production on time.”.

says Florian Schoiswohl, Project Manager at euroTalc

Green Mining

The concept of “green mining” has gained momentum in recent years as it seeks to improve the environmental performance of the mining sector. euroTalc has followed these principles as a mining business with a focus on ecological angles and a long-term understanding. Decisions regarding research, investment, and advanced technology acquisition are related to this interest.

The relationship between REDWAVE and euroTalc is based from the beginning on balancing these premises and achieving the objectives without compromising the required performance.

Improving practices and processes within the mines is indispensable on our way to more sustainable use of resources.

Mine Tour

We invite you to take a virtual journey together inside the Elisabeth Mine in Slovakia. State-of-the-art sorting technologies and an impressive mine operated by our customer, euroTalc – for the extraction and production of high-quality, pure talc – are waiting for you.