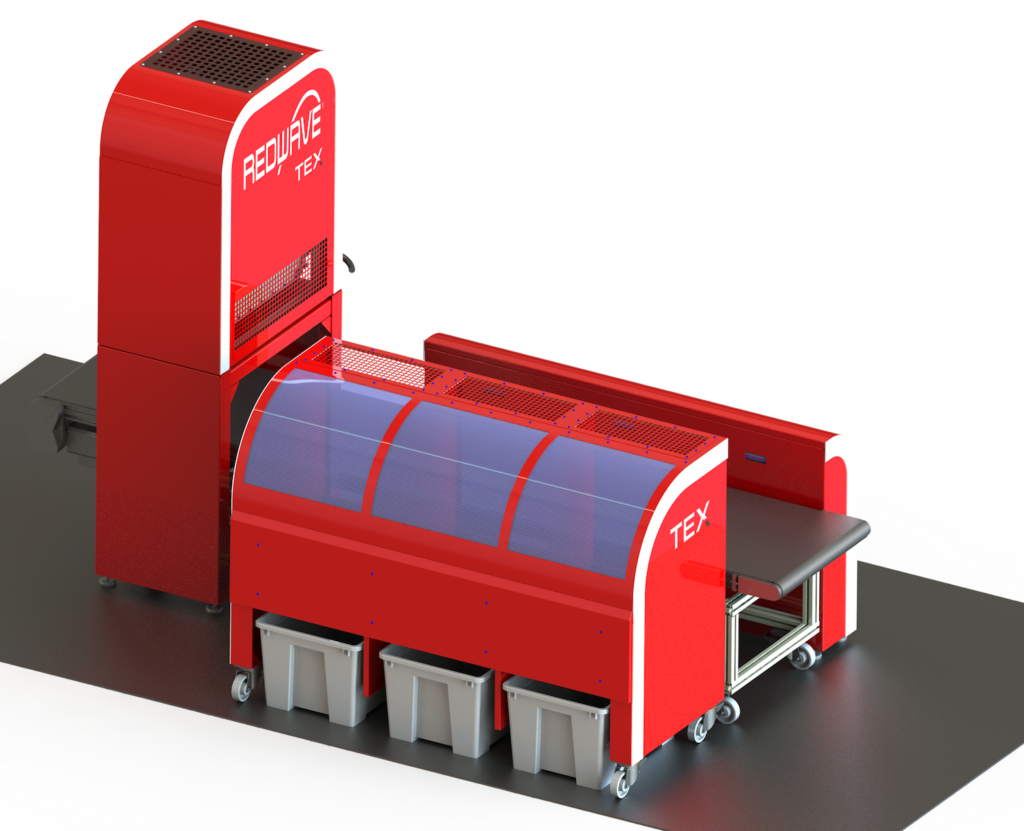

From G-string to jackets, REDWAVE TEX sorts materials according to predefined parameters and can handle two primary tasks: sorting whole garments for reuse and sorting shredded textiles for industrial processing.

What makes REDWAVE TEX stand out?

Precision: REDWAVE TEX’s sensor technology enables highly accurate identification and sorting of textiles according to predefined criteria.

Efficiency: REDWAVE TEX can process large volumes of textiles quickly and efficiently. The machine sorts textiles in record time, increasing productivity.

Customization: REDWAVE TEX can be customized to meet specific customer requirements. Whether it’s size, color, material composition or other parameters, REDWAVE TEX can be programmed accordingly.

Labor savings: By automating the sorting process, REDWAVE TEX significantly reduces the need for manual intervention, resulting in cost savings.

Flexibility: REDWAVE TEX allows customers to quickly adapt to changing market demands. Sorting criteria can be easily and quickly adjusted.

“We believe that REDWAVE TEX sets new standards in textile recycling. Our technology not only makes a significant contribution to resource conservation and environmental protection but also offers economic benefits to our customers,” says the REDWAVE R&D team.