Over the past 70 years, the company has grown up significantly with new innovative products and solutions to better meet the customers’ needs. Today, LEFORT is recognized as a leader in the design and the manufacturing of hydraulic shears, balers, and shredders for the scrap metal recycling industry. Over 70 years, LEFORT has built and delivered over 4000 machines worldwide.

Monoblock hydraulic shears and balers

Today our the LEFORT product range can be split into 2 categories :

Firstly, the small(er) machines, built in 1 piece and called Monoblock and secondly, the large machines called Multiblocks with a separate power pack. The monoblock hydraulic shears and balers have a cutting force ranging from 600 T to 1000 Ton. They have an operating weight between 45 an 100 Tons. They all have wrap around box (TS) which is very fast and efficient to process light scrap material. The monoblock machines are available either with a diesel engine or with an electric motor.

We have 4 versions available for sale:

- Stationary.

- Portable. This is a stationary machine with 4 hydraulic legs. So you can easily lift the machine and put it down on a trailer to move to another location.

- Mobile on wheels. Very popular machines during the past 40 years.

- Last but not least, the TRAX. New LEFORT innovation launched in 2016. Today this is the most popular hydraulic shear in Europe.

The monoblock product range is today very complete and is well meeting our customer needs.

Multiblocks hydraulic shears and balers – KOLOSS

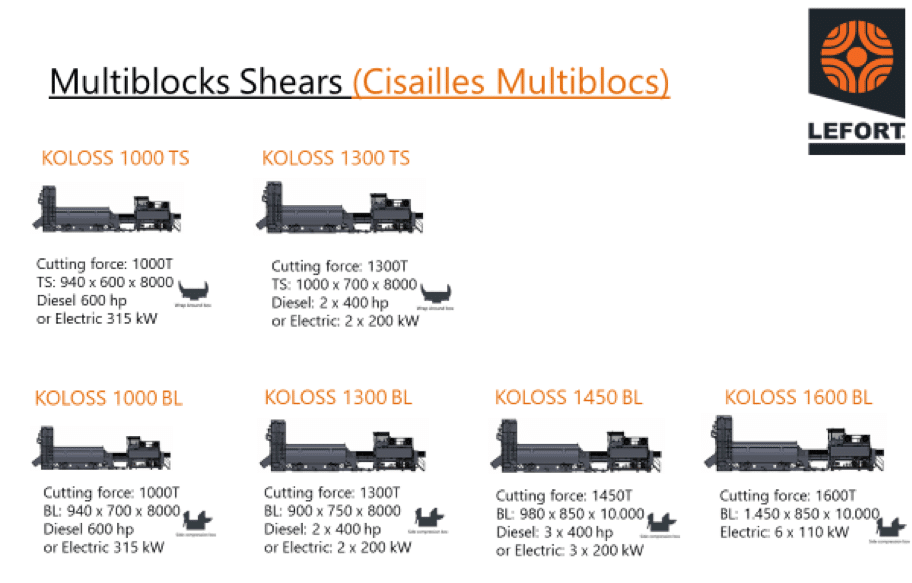

During the past 3 years, the Research & Development has been focused on the big machines with the objective to increase performance and productivity. Today, LEFORT is really proud to introduce its new KOLOSS product range consisting of 2 families: KOLOSS TS with a wrap around the box and KOLOSS BL with a side compression box.

- 6 models, all stationary machines with a cutting force from 1000 T to 1600 Tons.

- Operating weight from 115 Tons up to 500 Tons.

- We have developed a new box design: 10 meters long and 2.6 m wide for the 1450BL and 1600BL.

- Introduction of a new and additional model: the 1300 BL with a new box and new shear head.

You will have the opportunity to see the first Koloss 1300 BL in action today. During the factory tour, you will see the first Koloss 1450 BL under-construction. Those 2 new models have been sold and will be delivered to customer sites in June / July 2019 time frame.

KOLOSS 1300 BL

The KOLOSS 1300 BL is a new and additional model positioned between the KOLOSS 1000 BL and KOLOSS 1450 BL. This new model has been introduced to better meet customer demand in the growing segment of the 1300 cutting force.

The modular design of the KOLOSS 1300 BL does provide flexibility regarding machine configuration. The base machine can be easily equipped with hydraulic hopper, sorting table, shield extensions and/or shield extensions with the cross member.

The KOLOSS 1300 BL is also equipped with a Hold Down with combs/groove. The small grooves in the Hold Down as well in the shear head do prevent that small pieces of metal can come between the hold down and the shear head and block/jam the hold down when it is moving up. This feature is a unique LEFORT feature (Patented) and is already standard equipment on the smaller shears & balers.

- The guides (nylon made) of the Koloss 1300 BL have been significantly increased (2.6 meters long) to increase the durability of the crosshead.

- The new box design provides very good accessibility for easy and safe service from ground level.

- Box dimension : 8000 mm x 2350 mm (open).

- A new design (bolt + rod) introduced on the Koloss 1300 BL will also facilitate the blade change.

- Automatic lubrication system for the shear-head, box hinges, and hydraulic cylinders is standard equipment on the entire product range.

The Koloss 1300 BL can be powered either by 2 x 400hp diesel engines (optionally 2 x 600 hp) or by 2 x 200 kW electric motors (optionally 3 x 200 kW motors). Productivity : 35 – 50 T/hr