Effective from November 1st, 2024, REDWAVE and TOMRA Recycling will offer each other’s complementary metal sorting technologies directly to their respective customers. By facilitating access to the combined technologies in one go, both REDWAVE, a Competence Center of BT-Systems, and TOMRA Recycling aim to address the growing demand for sustainable and efficient Zorba sorting processes, enhancing scrap metal recovery and delivering the highest quality of end fractions. Customers can now source both technologies from one supplier, however REDWAVE and TOMRA will continue to operate fully independently, focusing on their individual technology expertise and directly assisting customers with after-sales service on their respective equipment.

Benefits in Zorba sorting

This non-exclusive agreement will be particularly beneficial to recyclers and plant operators in Zorba sorting, providing them with more efficient and accurate capabilities. Zorba, a mix of non-ferrous metals, requires a multi-step, precise process to maximize recovery and value. The combined technologies of REDWAVE and TOMRA are perfectly suited to meet these complex requirements.

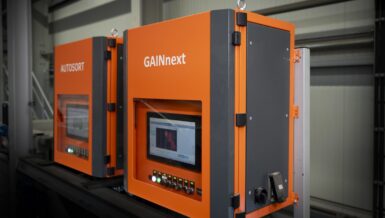

TOMRA Recycling’s industry-leading XRT sorting solutions are renowned for their ability to distinguish materials based on atomic density. Having been on the market for more than two decades, they are ideal for separating heavy metals from aluminum. REDWAVE’s XRF sorting solutions, also highly regarded globally, excel in recognizing materials according to their chemical composition, ensuring high-precision sorting of the recovered mixed heavy metals into mono-metal products such as copper, brass or zinc.

Shared vision and complementary technology

“Both TOMRA Recycling and REDWAVE – the Competence Center for Recycling & Sorting Solutions of BT-Systems GmbH – share the vision for a circular economy and net-zero emissions. While both companies remain independent and focused on their individual strengths, together we make it easier for our customers to efficiently upgrade scrap metal, achieve the highest quality standards and promote sustainability and efficiency,” says Gerald Kreiner, CEO of BT-Systems GmbH.

Tom Jansen, Segment Director Metal, Sales at TOMRA Recycling, added, “We are thrilled to offer our customers a complete solution by working with another global industry leader in metal sorting. Our complementary technologies offer customers the advantage of one turnkey solution for their needs.”

The combination of the two companies’ advanced sorting technologies and REDWAVE’s plant-building expertise is anticipated to benefit a wide range of industries, from automotive to electronics, by providing higher-quality recycled materials. This agreement underscores the commitment of REDWAVE and TOMRA Recycling to driving innovation and sustainability in the recycling sector.