Tire recycling innovations continue to be of significant importance as the need for new sustainable, circular end-use markets.

Recent tire recycling innovations include:

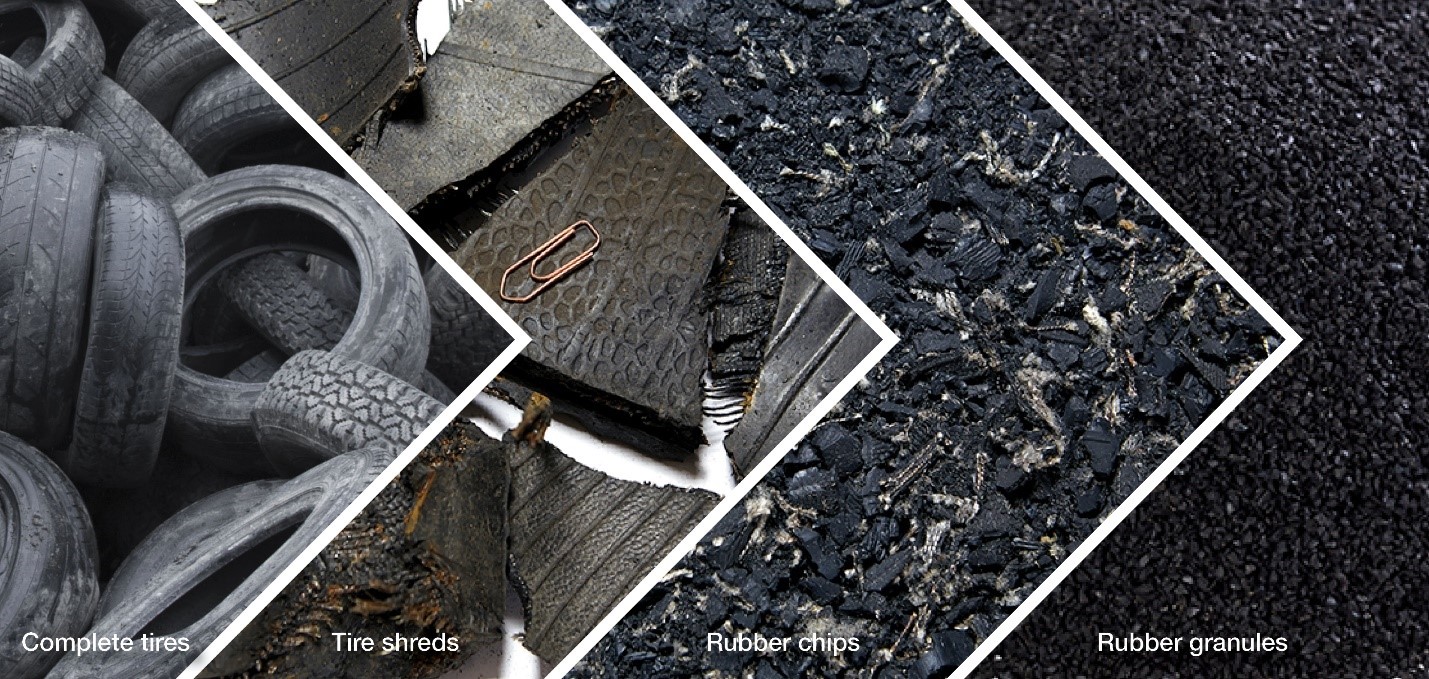

Genan takes in all types of tires – from cars, vans and trucks – and in a highly technological production process separates them into their original elements: rubber, steel and textile fibers. The output consists of 75 percent rubber powder and granulate, 15 percent steel and 10 percent textile fibers.

Australian tire recycler Green Distillation Technologies (GDT) partnered with CarbonScape, a company based in New Zealand, to turn the carbon created in its recycling process into high value graphite.

Wastefront, a rubber waste recycling company, converts disused tyres into useful commodities, including liquid hydrocarbons and carbon black, which can then be reutilised in processes such as alternative fuel manufacturing or ground rubber production.

Danish manufacturer of tyre recycling equipment, ELDAN Recycling A/S, has developed a new sensor-based system to detect foreign objects in tyre shreds and reduce the risk of breakdowns and yearly down time.

Projected to solve a big issue in the mining field, the HYPERTYM™ integrated mobile unit reduces of all OTR mining tires and all oversized tires up to 63”, allowing for easy recycling and disposal of used tires.

The unique Pyrum-Thermolysis is a thermal dismantling of organic substances respectively rubber and plastic waste under exclusion of oxygen.

RubberJet Valley is a chemical specialty company specialized in the production of engineered raw materials (Polymers) called RubberJet Powder (RJP ™) and RubberJet Granules (RJG ™) capable of replacing virgin raw materials (for example Natural Rubber) in a wide range of applications including which mixes new tires.