The Problem: Dust Emissions in Recycling

Recycling plants have long been grappling with the issue of dust emissions generated by conventional conveyor belt systems. Dust not only poses health and safety concerns for workers but also contributes to environmental pollution. Additionally, dust can hamper equipment functionality, leading to frequent maintenance and downtime, thereby reducing overall productivity.

For a Canadian recycling company, these issues were becoming increasingly troublesome. The facility processed a significant amount of plastic and paper materials daily, and the existing conveyor belt system was producing copious amounts of dust. This was not just a nuisance; it was also a costly problem that needed a sustainable solution.

Modulex’s Innovative Approach

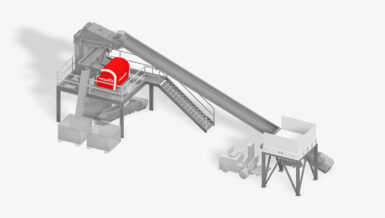

Recognizing the need for a more efficient and dust-free material handling solution, Modulex turned to the Archimedys modular auger. This innovative auger system is designed to convey and feed materials effectively while significantly reducing dust emissions.

The Archimedys modular auger consists of a helical screw that rotates within a pipe, creating a sealed environment for material transport. This enclosed design prevents dust and particles from escaping, ensuring a cleaner and safer working environment. Modulex realized that by integrating this technology into their recycling process, they could overcome the challenges posed by dust emissions.

Key Benefits of the Archimedys Modular Auger

- Dust Elimination: The most prominent advantage of the Archimedys modular auger is its ability to virtually eliminate dust emissions. The sealed pipe enclosure ensures that dust and particles stay contained, minimizing health risks to workers and reducing environmental pollution. This feature alone greatly improves the overall sustainability of the recycling process.

- Improved Efficiency: By replacing the traditional conveyor belt with the Archimedys modular auger, Modulex witnessed a remarkable increase in operational efficiency. The auger’s continuous and controlled material flow results in reduced spillage and material loss, ultimately leading to higher throughput and reduced waste.

- Reduced Maintenance: Conventional conveyor belts require regular cleaning and maintenance due to dust buildup, which can be time-consuming and costly. With the Archimedys modular auger, maintenance is significantly reduced, as there is no accumulation of dust on the equipment. This means less downtime and lower maintenance expenses for the recycling company.

- Versatility: The Archimedys modular auger is highly adaptable and can be customized to handle various materials and accommodate different angles and inclinations. This versatility allows recycling facilities to streamline their processes and handle a wide range of recyclable materials efficiently.

- Energy Efficiency: The auger’s design requires less power compared to traditional conveyor belts, contributing to energy savings and reduced operational costs. This aspect aligns with the global push for more sustainable and energy-efficient practices in recycling.

Implications for the Recycling Industry

Modulex’s successful integration of the Archimedys modular auger offers promising implications for the recycling industry as a whole. By addressing the long-standing issue of dust emissions, this innovative solution sets a new standard for environmentally responsible recycling practices. The benefits realized by Modulex in Canada demonstrate that similar recycling facilities worldwide could achieve similar results.

Furthermore, the Archimedys modular auger showcases the potential for modernizing recycling processes to make them more efficient and cost-effective. As recycling becomes an increasingly vital component of global sustainability efforts, such innovations are crucial in advancing the industry’s capabilities.

Modulex’s pioneering application of the Archimedys modular auger in their Canadian recycling facility is a testament to the transformative power of innovative technology in addressing industry challenges. By replacing a traditional conveyor belt with this state-of-the-art solution, Modulex not only eliminated dust emissions but also significantly improved efficiency, reduced maintenance costs, and enhanced sustainability.

This case study serves as an inspiring example for recycling companies worldwide, demonstrating the potential to revolutionize their operations while prioritizing safety, efficiency, and environmental responsibility. As the recycling industry continues to evolve, innovative solutions like the Archimedys modular auger are poised to play a pivotal role in shaping its future.