Based on the experience of various successfully running processing plants for metal composites, it could be shown once again that especially the long-standing SICON process know-how provides the decisive advantage to the perfect end product.

After the usual material disintegration in the vertical shredder, it is the carefully coordinated subsequent process steps that guarantee pure end products (Fe without copper impurities, copper, aluminum).

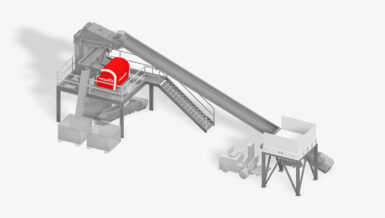

The heart of the plant is a vertical shredder, which is characterized by excellent material disintegration due to its rotor design. Shredder and conveyor technology are optimally matched to each other, so a very clean Fe fraction can be separated as the first cut. To increase efficiency, the SICON overbelt magnet has an extended cleaning zone; in addition, the Fe fraction is cleaned again on the PrimeScrap. This eliminates any loss of copper in the Fe fraction! An excellent marketable Fe fraction is produced.

In two further process steps, the non-Fe fraction is separated into pure aluminum and a copper-rich fraction for further refining in the EcoShred® Imtec. The aim here is to minimize the generation of fines. Particularly in the case of aluminum fractions, pulverization – as practiced by other suppliers – is equal to value destruction.

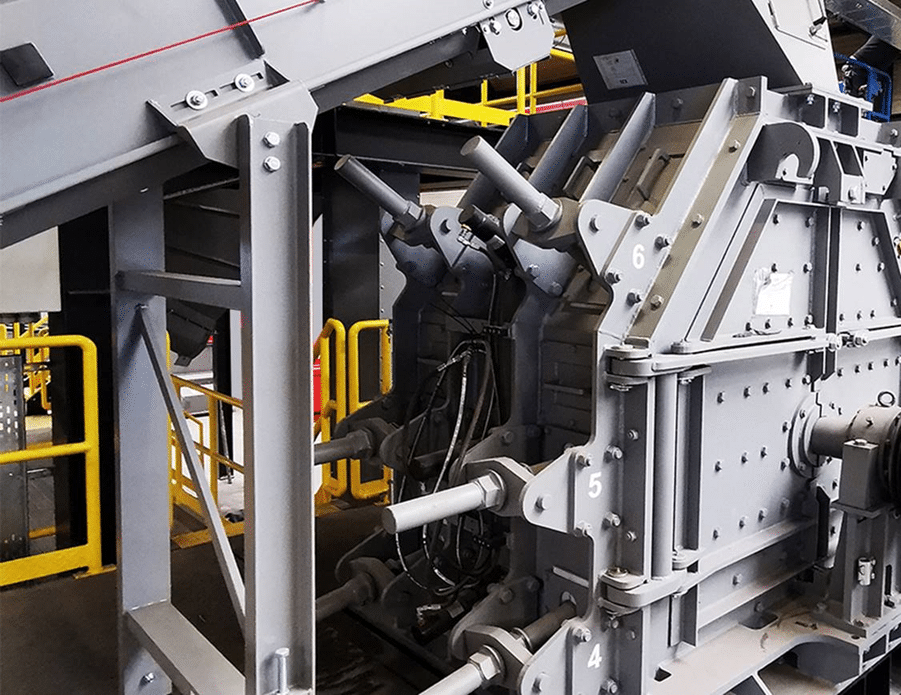

In the EcoShred® Imtec, gentle entanglement takes place. This serves to improve separation on the air separators (AirFloat). The EcoShred® Imtec is characterized in particular by the fact that it operates at a relatively low speed (700 to max. 1,000 rpm). The grinding distance of the stator tools can be very easily adjusted hydraulically and thus kept constant. Quality fluctuations are avoided and copper purities of well over 99 % can be achieved.

The SICON process for metal compound preparation is modular in design. This increases flexibility and adaptability to different feed materials and thus ensures high plant availability. In addition, individual customer requirements can be taken into account at any time.