Benefits:

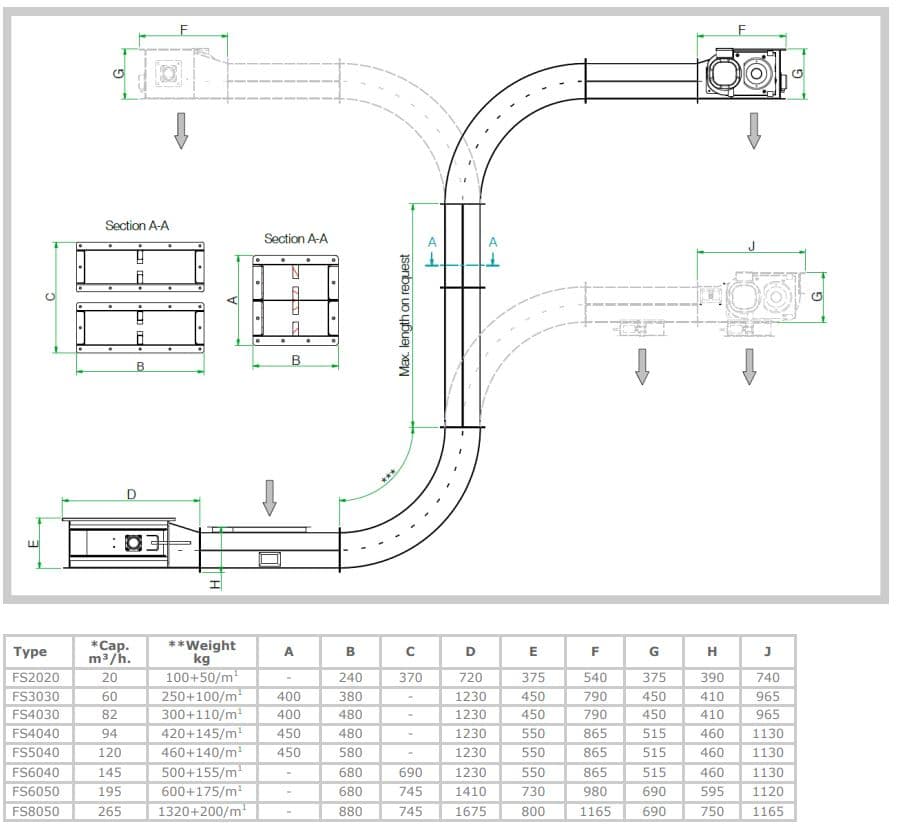

- compact design.

- minimum height required, not creating fines/dust (“angel hair”)

- very low noise emission compared to pneumatic conveying

- very low energy consumption (approx. 1.75 kW, 8 tons / hour, 6 m height, 2 horizontal

- less external costs for control / cabling/ software.

- almost zero product contamination

- low investment costs

- almost zero maintenance costs

The machine is well suited for use in circular processes and is also suitable for powders even for very fine products such as Carbon Black, or very aqueous milk powders. In terms of Atex, no additional provisions are necessary, due to a low speed (v < 0.5 m/s)

- food recycling (bread, potato chips, carrot granulate, etc)

- circuit boards recycling

- metal powders from residual flows

Two test setups are ready at the Tegelen location for testing with your products.