With the application and development of magnetic separation technology, magnetic separation equipment is constantly updating and replacing, and dry magnetic separation has experienced remarkable technological progress over the past twenty years.

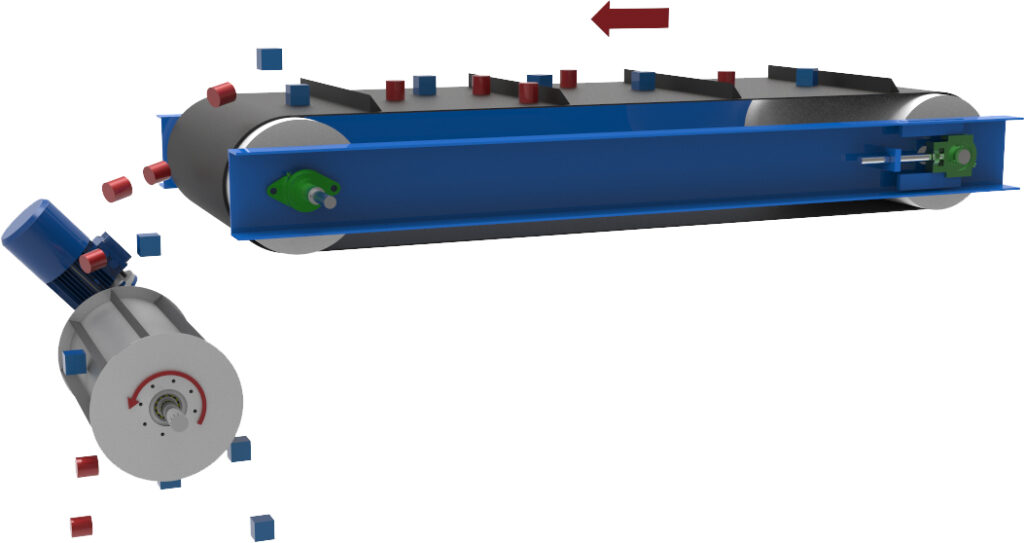

There are many new ideas and techniques applied in magnetic separators. So far, dry magnetic separators have developed many different applications for mineral and coal processing, for induction roller magnetic separators for chromite. Cross-belt magnetic separator for removing harmful magnetic particles and paramagnetic particles. The lifting roller magnetic separator is used in the heavy mineral industry to separate garnet from monazite and rutile. Rare earth drum magnetic separator for fine feed dry magnetic separation sorting process and rare earth roller magnetic separator for zircon and rutile in heavy mineral sand industry. These magnetic separators have different applications, and the dry magnetic separator is also moving toward large-scale and relatively easy-to-manufacture.

Although Dry magnetic separators are a common type of equipment for separating magnetic particles from nonmagnetic particles or relatively strong magnetic particles from relatively weak magnetic particles…, the separation efficiency is not satisfactory when fine-grained particles are processed because of their strong tendency to aggregate.

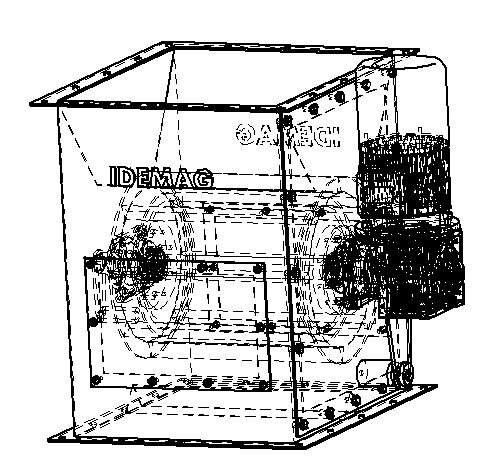

The separation efficiency of a dry magnetic separator depends on the optimization of the material characteristics and process variables, as well as the design characteristics of the equipment. However, previous studies on dry magnetic separators have neglected the influence of the separation chamber shape on the sorting efficiency.

Therefore, three dry magnetic separators with separation chambers with different shapes are investigated, and a multiphysics coupling model is developed to simulate the separation process of fine magnetic particles in these three dry magnetic separators.

The predicted results show that the wavy-shaped separation chamber (WSC) can promote the irregular movement of the airflow and then generate a large amount of vortex to promote the dispersion of particles.

Moreover, the WSC can effectively improve the recovery of magnetite and high-grade intergrowth particles and the separation efficiency of the equipment.

Recent testing of combined magnetic separators’ sorting principles have lead us to develop a new concept for improving the separation efficiency of fine multiple magnetite by means of enhanced Eddy-Current (or Foucault) magnetic separator machines.