The recycling plant sorts materials received through the WEEE circuit, which refers to recycling and disposal of electrical and electronic products at the end of their life cycle, in this case primarily from refrigerators.

The polystyrene selection process occurs in multiple stages.

Firstly, the material is homogenized in silos. Next, the critical cleaning phase begins, where the Cimbria Delta Screen Cleaner removes powder and fine elements. The Delta Screen Cleaner combines a sophisticated system of dust removal, suction, and granulometric separation, resulting in consistently efficient and precise separations.

Metal separation follows, ensuring that both magnetic and non-magnetic metals are removed from the cleaned product. Leading to the most pivotal stage of the process: the optical sorting phase.

The two Cimbria SEA.HY Optical Sorters in the plant, equipped with SWIR and Full Color RGB hyperspectral cameras, are designed for polymer selection that recognizes the chemical nature of different elements and identifies millions of color shades. With this technology, SEA.HY sorters can distinguish polymers of the same color but different materials, achieving a purity that meets the recycling market standards by separating materials into streams of identical products.

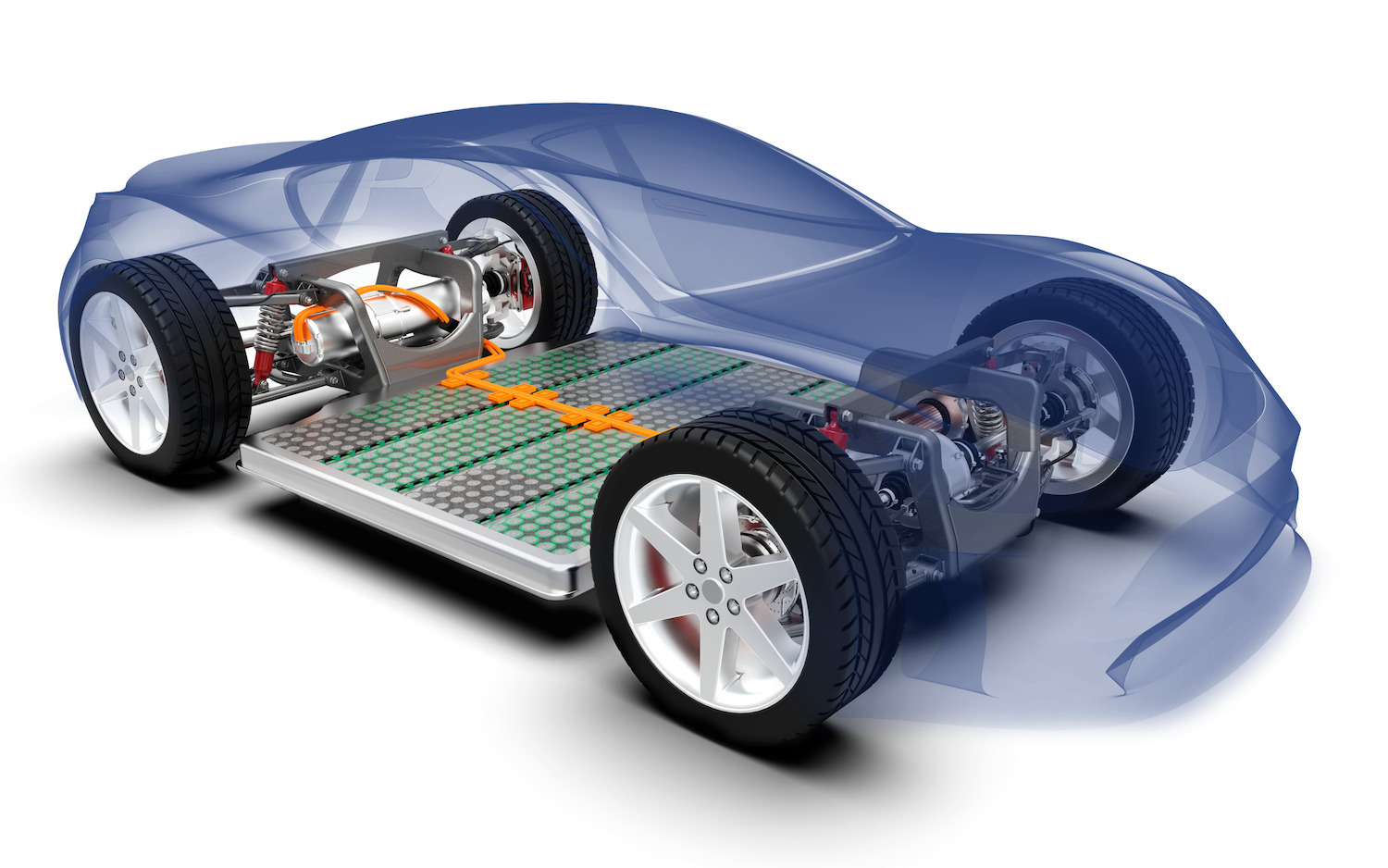

The result of the process in the Plastisavio plant in Bertinoro is coils of extruded polystyrene, produced at a rate of 2,000 kg/h of incoming product. The outlet applications are multiple, from the packaging industry to the automotive sector, to construction and horticulture.

The waste from polystyrene production is in turn recycled: the separated metals are reused, as are other polymers, which can be further divided and sold, such as PP and PVC. The polystyrene recovered in the Bertinoro plant is used in Plastisavio’s plant in Mercato Saraceno, where they also have optical sorting plants for PET equipped by Cimbria, while other selected plastic materials are used in other manufacturing industries.

The integration of Cimbria Optical Sorters in both Plastisavio plants offers several advantages to Plastisavio. On one hand, these machines are configured to perform specific tasks needed, resulting in improved production efficiency. On the other hand, by utilizing these best-of-class sorter solutions, Plastisavio has significantly reduced its reliance on external suppliers for recycled materials by producing internally, in Bertinoro, the raw material necessary to feed its plant in Mercato Saraceno, significantly optimizing their value chain.

The groundbreaking dry polystyrene recycling from WEE at the new Plastisavio plant in Bertinoro represents a remarkable leap forward. By adopting this dry treatment approach, yielding substantial benefits, the plant not only minimizes waste but also achieves significant energy savings, making it both environmentally and economically sustainable.