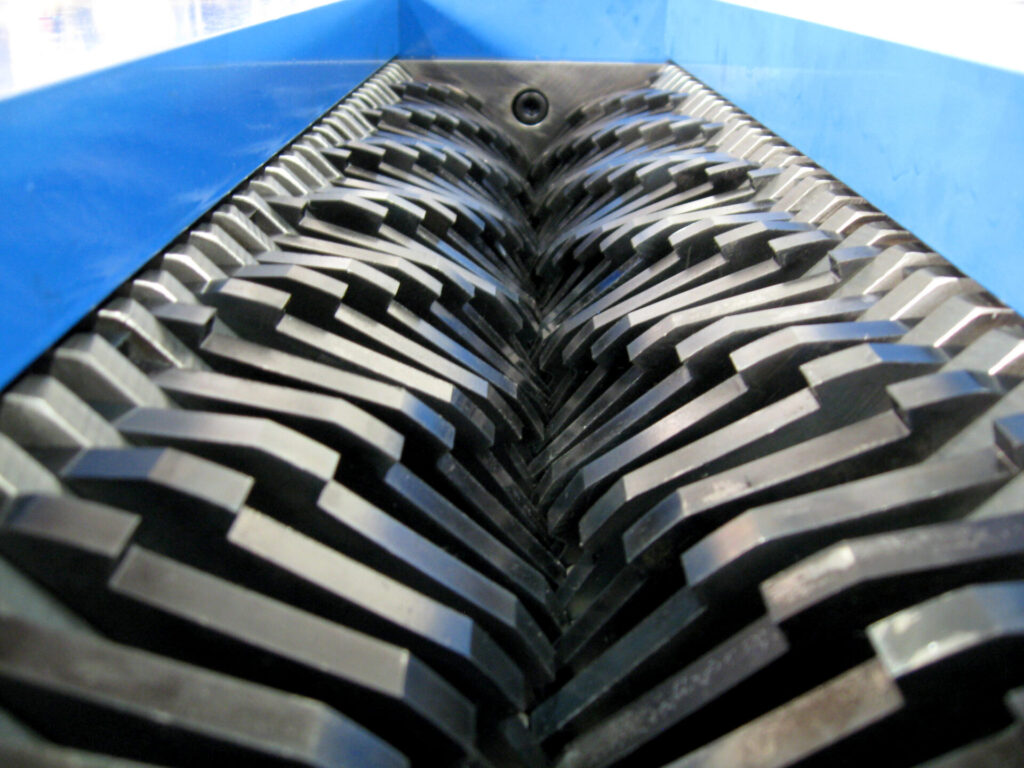

In high-output shredding operations, equipment downtime is one of the most significant threats to productivity and profitability. Nowhere is this more apparent than in the maintenance of shredder heads, the core mechanical assemblies in industrial shredders responsible for the material reduction process. These heads, composed of rotating shafts, knives, bearings, and hydraulics endure extreme mechanical loads and high-torque conditions and knife wear can cause both failures and low production.

Unfortunately, traditional methods for restoring shredder heads to full functionality typically involve extensive and costly rebuilds that result in substantial operational downtime. Rebuilding a shredder head presents a complex challenge that demands specialized expertise, precision tools, and strict adherence to tight engineering tolerances. Issues such as misalignment, incorrect knife gaps, and overlooked wear points can result in reduced performance or early failure.

Furthermore, internal rebuilds often fall short due to a lack of specialized equipment or training, increasing the likelihood of operational issues post-reassembly. The resulting downtime, combined with the labor and logistical costs of a full rebuild, places a heavy burden on operators.

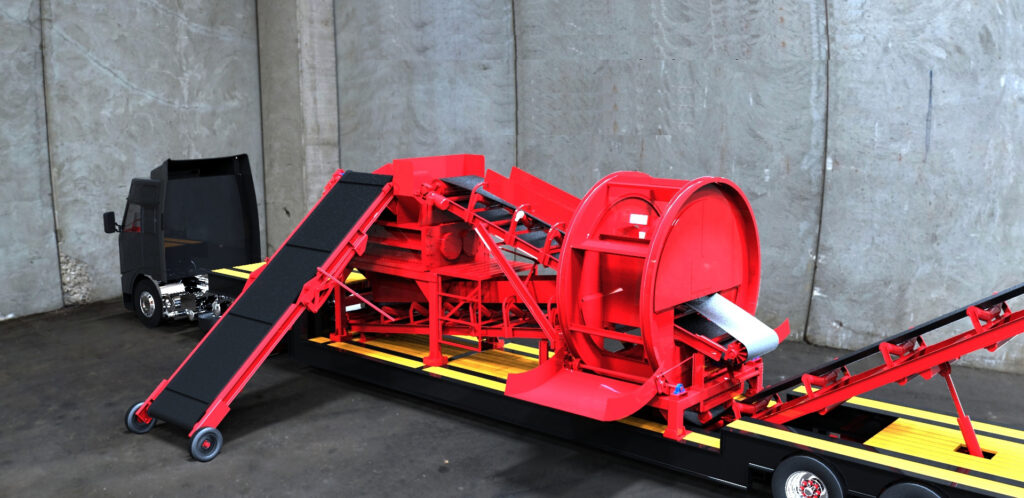

As a result, a growing number of processors are shifting their strategy away from in-house or third-party rebuilds in favor of complete shredder head swaps. This approach significantly reduces downtime—often restoring machines to full function in under an hour—and ensures that rebuilt components meet strict OEM specifications.

“Instead of navigating the challenges of disassembly and reassembly, operators can perform a quick head replacement and immediately resume production, maintaining uptime and minimizing disruption,” says John Neuens, Industrial Consultant at BCA Industries, a Milwaukee-based OEM specializing in custom recycling systems.

The swap-and-go methodology eliminates the need to retain specialized technicians on-site, reduces the risk of rebuild errors, and offers a more predictable maintenance cycle. Ideally, the process should include a factory warranty when factory rebuilt.

In-house or Third Party Rebuilds

Although some processors believe they can effectively disassemble and reassemble the unit themselves, the process is complex and requires specialized knowledge, custom-built jigs and fixtures to assist with disassembly and reassembly, and adherence to strict tolerances to ensure proper function and longevity.

“Despite their outwardly rugged appearance, shredders are precision-engineered machines with tightly controlled tolerances that must be maintained to achieve effective and consistent material shearing,” says Neuens. “Most of our knives are an AR500 base alloy, super abrasion resistant, with a hard-face welded edge. It can be difficult just finding a knife rebuild service to rebuild them correctly, much less a technician who has the skills needed in the shredder business.”

Disassembly introduces additional complications, as components are frequently dirty, worn, or corroded, often requiring forceful removal. Even seemingly simple tasks, such as assessing the condition of components like bearings and keyways, require experience, as factors like grease line condition play a role in the success or failure of a rebuild.

While OEMs like BCA offer instructional videos to walk customers through the head rebuilding process, Neuens says these videos typically can range from two to three hours in length given the complexity and variables involved. After viewing the video, many customers ultimately choose not to undertake the work themselves.

“Most processors do not have the in-house resources to complete this work to specification, and hiring a qualified mechanic or millwright is costly. At the same time, most independent shops are not equipped to meet the required standards,” says Neuens, adding that even when the work is performed by the OEM’s technicians, shredder head repairs and part replacements can take 16 to 40 hours to complete.

Quick Shredder Head Swap-Out

As a cost-effective alternative, BCA offers a comprehensive Shredder Head Rebuilding Program designed to minimize operational downtime and extend the lifespan of its shredding equipment, including the ES1000, PD1000, Triplus, and The Beast 2000 series.

The company’s innovative modular head design enables the replacement of a dull shredder head with a sharp one in under an hour. High-production customers frequently purchase a second head to eliminate downtime, using the quick-change capability to maintain continuous production.

Further repairs, such as knife replacement, can then be performed safely offline, or the used head can be returned to BCA for professional rebuilding. BCA manages the entire process end-to-end. At their site, customers remove the shredder head, securing it on a custom-designed stand with BCA coordinating all freight logistics, performing the complete rebuild, and returning the refurbished unit to the owner generally within 7-14 days if they have a second set of knives. If BCA rebuilds the knives that are in the dull head, it may take longer.

Once at BCA’s facility, the head rebuilding process goes beyond part replacement. Each shredder head is completely disassembled, cleaned, inspected, and reassembled with engineering adjustments based on proven field performance data.

The knives are removed from the shafts, re-sharpened, hard-faced, and re-ground. If the customer arranges for a spare set of knives as part of the program, the turnaround time is further expedited. Spacers are welded and re-machined to size, and any worn bearings or chains are replaced.

The process also includes inspection of shafts, keys, super nuts, and sprockets, resetting of journal ends, and bearing push adjustment for uniform engagement. Each unit is thoroughly cleaned and lubricated, returning the head to original factory condition.

Design adjustments and tolerance verifications are carried out methodically to ensure the rebuilt head meets or surpasses the OEM’s original performance specifications. Any component wear or alignment issue is corrected based on engineering standards and field data. If design improvements have been developed since the original build, these are applied during the rebuild.

Once the head is returned to the customer, the operator removes it with a forklift taking it off the stand, fastens four bolts, connects six hoses, and completes the installation. Each head is engineered to be light enough for standard LTL freight on a single custom BCA steel pallet.

With a rebuild program from the factory that built it, “Customers know they can send the head in, receive a professionally rebuilt unit, and have a warranty in place. If there are any problems in the future, it will be addressed by the factory technician. But if the work is done internally at his business and issues arise, the customer bears the full cost,” says Neuens.

Shredder head rebuilds continue to be one of the most persistent and costly maintenance challenges in the industry. These rebuilds are both time-consuming and expensive, often occurring at highly inconvenient times. The shredder head and knife maintenance is responsible for approximately 90% of the total lifetime maintenance cost, establishing it as the most significant wear component in the system.

For industry professionals, swapping out shredder heads instead of rebuilding them offers a smarter, more efficient path forward. Instead of sinking time and money into repeated, time-consuming rebuilds, they can minimize downtime, reduce maintenance costs, and keep production running smoothly with ready-to-go replacement heads.

For more information: call 414-353-1002; fax 414-353-1003; email john@bca-industries.com; visit http://www.bca-industries.com; or write to BCA Industries, 7036 N Teutonia Ave., Milwaukee, WI 53209.