The Challenge

For food manufacturers, handling waste from expired or non-compliant products presents both logistical and environmental challenges. Traditionally, such waste was disposed of in landfills, leading to increased environmental burdens and wasted resources. The client sought a more sustainable and cost-effective approach to recycling these products while ensuring compliance with environmental regulations.

The ITS Solution

ITS engineers collaborated closely with the company to develop a customized recycling system capable of efficiently separating food waste from its glass packaging. The process unfolds in multiple stages, each designed to maximize material recovery and minimize waste:

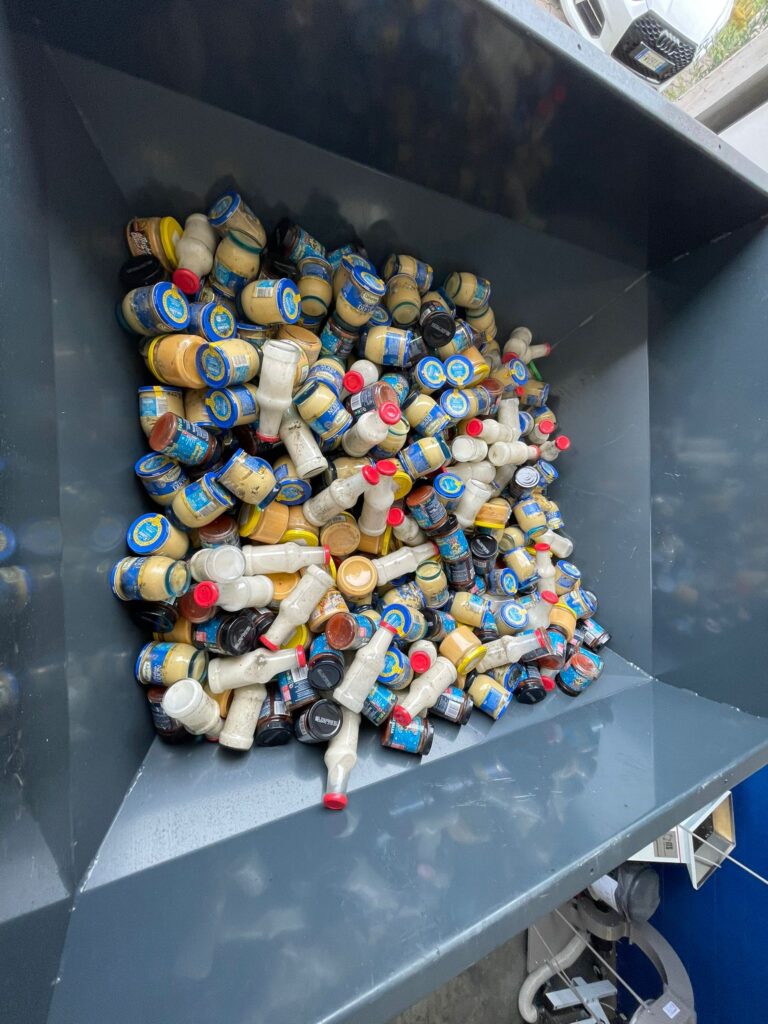

- Primary Shredding – The first step involves feeding the bottled sauces into a robust shredding unit. This shredder breaks the glass containers into large fragments, facilitating the release of their liquid or pasty contents.

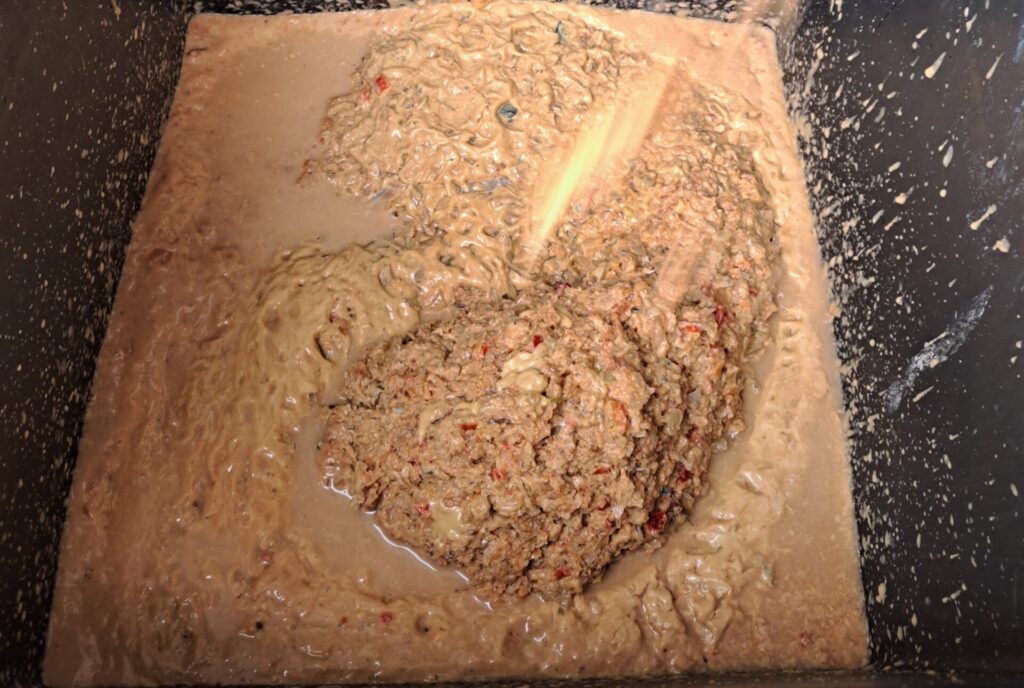

- Gravity Separation & Vibrating Screening – The shredded material is then directed onto a vibrating screen with multiple levels of separation, each one with its specific screen sizes. This step helps separate the food waste from the glass components. The screen’s design ensures that larger glass fragments remain on top, while smaller particles pass through for further processing.

- Spray Liquefaction & Food Waste Extraction – A high-efficiency spray system liquefies the food waste, washing it into holding tanks. This step ensures optimal separation of organic material, preventing contamination of the glass fraction

- Glass Washing & Separation – The larger glass pieces are subjected to a thorough washing process before being discharged into dedicated containers for further recycling. Meanwhile, the middle-size fraction, primarily composed of smaller glass particles, undergoes an additional washing cycle to ensure complete separation from food residues.

Sustainable Outcomes

This advanced recycling system not only optimizes waste disposal but also promotes a circular economy by repurposing the separated materials:

- Organic Waste to Bioenergy – The extracted liquid containing organic residues is directed to a biogeneration station, where it serves as a valuable input for renewable energy production.

- Glass Recycling & Reuse – The separated glass fractions are sent for remelting and used in the production of new glass products, reducing the demand for raw materials and lowering carbon emissions associated with glass manufacturing.

A Step Towards Greener Industry Practices

The successful implementation of this ITS-supplied system demonstrates the potential of size reduction technologies in transforming industrial waste management. By integrating shredding, screening, washing, and separation processes, the solution not only reduces landfill dependency but also creates value from what was once considered waste. This case study serves as an inspiring example for other industries seeking to adopt sustainable waste management practices.

With such innovative solutions, companies can effectively balance production efficiency with environmental responsibility, paving the way for a more sustainable and resource-efficient future.