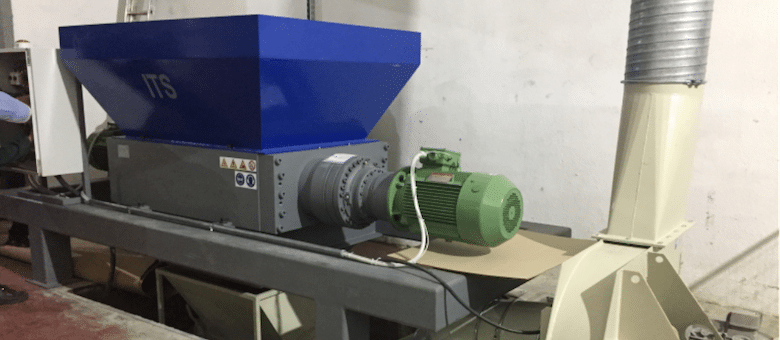

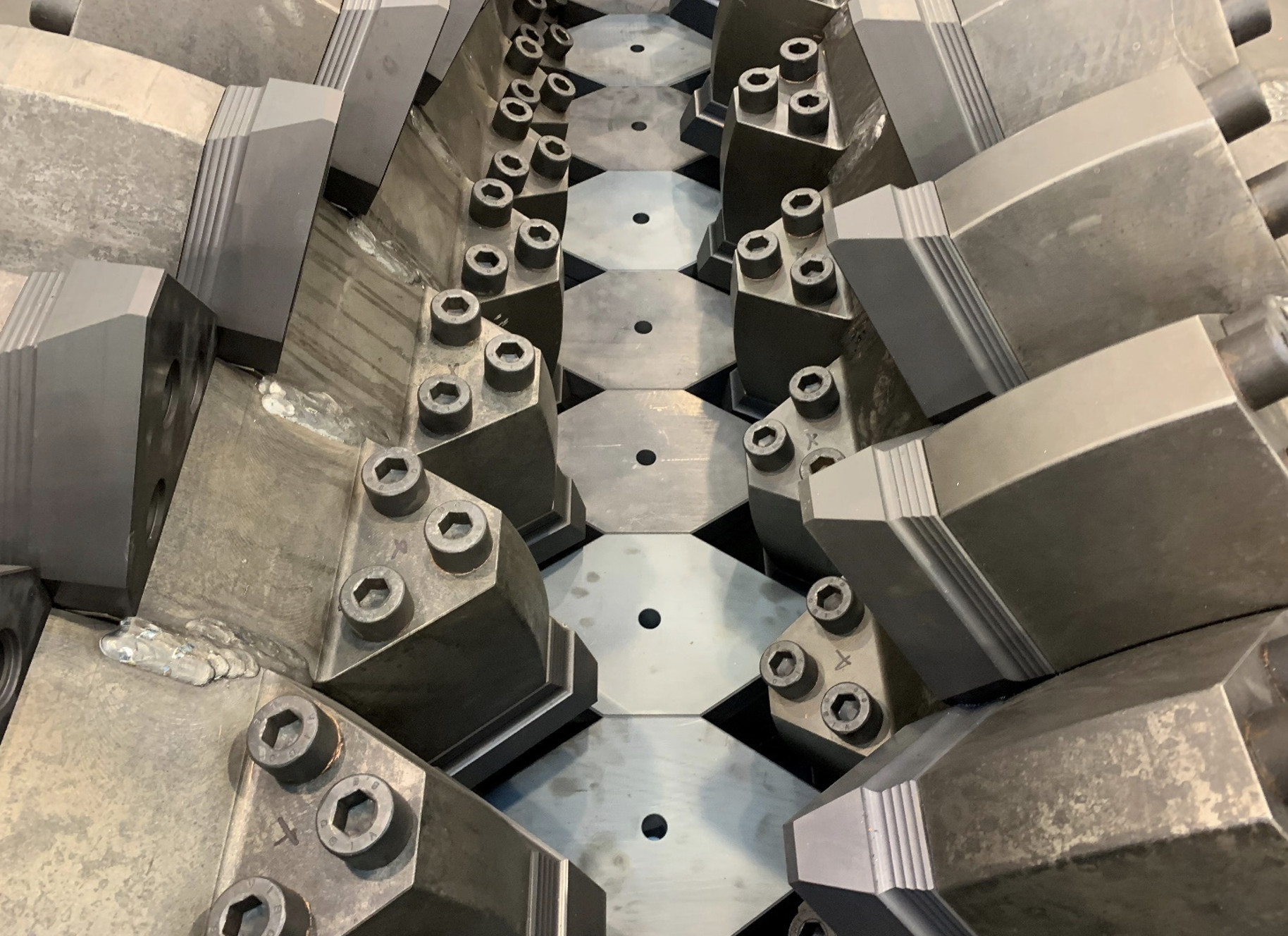

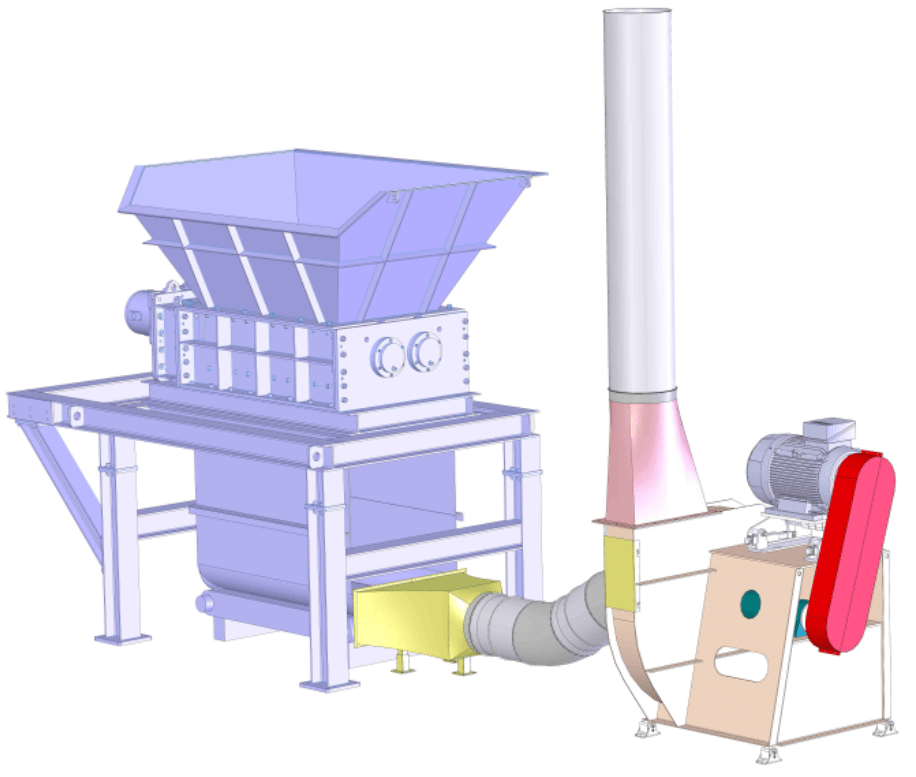

This shredder has been designed to cut cardboard trim and rejects coming directly from the production lines. Once the discarded material has been reduced to an adequate final size, a pneumatic transport system fitted underneath the shredder conveys the shredded cardboard to the bailing presses placed outside the production hall.

By implementing this solution the plant manager was able to eliminate the constant presence of a forklift circulating inside the production hall which was required in order to continuously collect the rejected material and transport it to the outside bailing presses.

Once the bales have been formed, they can be efficiently transported to the pulping facility for the production of new cardboard fibers.

A major benefit of this solution engineered jointly by ITS—Shredding & Grinding Solutions together with NEW AERODINAMICA, a leading specialist in pneumatic transport systems, was both in terms of a safer working environment and a reduction in operational costs due to the elimination of the forklift.