Video

Discover TOMRA Recycling’s New Metals Test Center | Put Our Machines to the Test!

With decades of expertise in metal recycling, TOMRA is a global leader in sensor-based sorting solutions. Our advanced technologies help recyclers recover valuable metals with high precision, ensuring maximum yield and purity. Whether it’s aluminum, e-scrap, or non-ferrous metals, TOMRA’s solutions improve material recovery rates, reduce waste, and enhance profitability.

Robot Sorting Cartons in Australia

Tetra Pak, a leading packaging company, sought to enhance the recovery of recyclables in Australia. They approached the sorting center APR (Australian Paper Recovery with a challenge to increase the tonnage and purity of sorted materials.

Salling Group turned costs into revenue with a baler from Presona

In 2023, Salling Group stopped paying an external company to handle OCC and plastic from approximately 250 of its stores in western Denmark and began collecting and baling the material themselves, which is then sold and generates profit.

PET Bottle vs PET Tray Sorting | TOMRA Success Story

Recycling PET plastic is becoming increasingly complex as regulations evolve and purity standards rise. At Amarsul, a leading waste sorting facility in Portugal, the challenge was to efficiently separate PET bottles from PET trays to comply with new Portuguese recycling requirements. With AUTOSORT™ and its advanced SHARP EYE™ technology, Amarsul has successfully optimized its plastic sorting process, achieving a 92% separation rate of PET trays from PET bottles.

Transforming Resource Recovery | Our Story | TOMRA Recycling

At TOMRA Recycling, we are committed to revolutionizing resource recovery and enabling a true circular economy. With around 10,000 systems operating in over 100 countries, our cutting-edge sorting technology is helping recyclers and metal recovery facilities maximize material value, improve efficiency, and reduce waste.

AI-Powered Sorting of Food-Grade Plastics | PET, PP, HDPE | TOMRA GAINnext™

Recycling food-grade plastics is one of the biggest challenges in achieving a truly circular economy. Until now, separating food-grade plastics such as polyethylene terephthalate (PET), polypropylene (PP), and high-density polyethylene (HDPE) from non-food-grade materials has required manual sorting. With TOMRA GAINnext™, recyclers can now achieve over 95% purity in food-grade plastics - fully automated and at scale.

Harden’s Smart Shredding: From Industrial Waste to Circular Fuel

The entire processing system is designed with a focus on modularity, integration, and automation, ensuring optimal efficiency and environmental compliance.

AI-Powered Sorting of UBC | Aluminum Can Recycling | TOMRA GAINnext™

Recovering used beverage cans (UBC) represents a massive opportunity for aluminum recyclers, but maintaining high purity levels has traditionally relied on manual quality control, leading to higher labor costs and inefficiencies.

How Robotized Sorting Lines Transformed 3Wayste’s Operations

3Wayste faced challenges in automating quality control while reducing labor-intensive tasks.

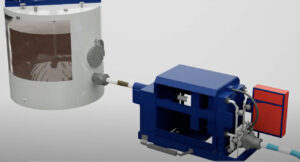

The Phosphorus Recovery Process Of AIK Technik AG

With our patented process, Leachphos, phosphorus can be extracted from the ashes of sewage sludge incineration. The result of this process is a finished product: a fertilizer powder that can be applied directly to the fields.

PET Purification with AI-powered Sorting | Bottle-to-Bottle Recycling

Recycling post-consumer PET bottles into high-quality, food-grade material for bottle-to-bottle recycling requires exceptional purification. That’s where TOMRA’s GAINnext™ comes in – an AI-powered sorting solution designed to maximize PET purity and unlock new revenue opportunities for recyclers.

Unrivaled PET Purification With AI-Powered Sorting | TOMRA GAINnext™

Recycling post-consumer PET bottles into high-quality, food-grade material for bottle-to-bottle recycling requires exceptional purification. That’s where TOMRA’s GAINnext™ comes in – an AI-powered sorting solution designed to maximize PET purity and unlock new revenue opportunities for recyclers.