The stationary breaker design allows the processing of rails of up to 120 m in length. A magazine is used for feeding the rails into the breaker.

There is also a mobile version for direct use on the rail track, fitted with a diesel power unit and loading rig. It can efficiently break rails of around 24 m into short sections measuring 300 to 1000 mm.

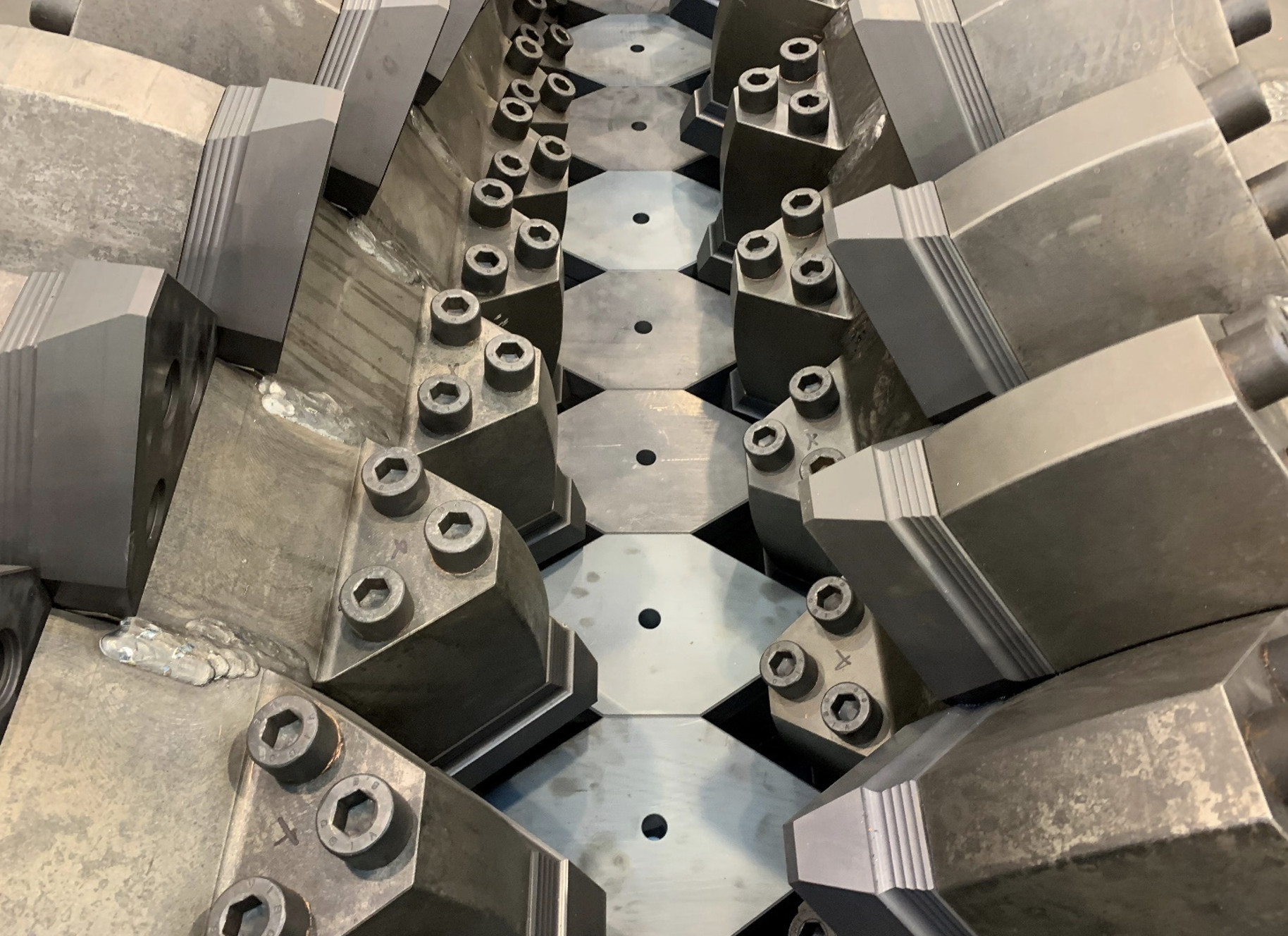

The mobile rail breaker, which is fitted on an extendable semi-trailer, can be moved to a different location very quickly. A special notching and breaking process ensures that the rails are broken with minimum tool wear.

Upon your request, Arno®Break can be delivered in combination with our digitization package for optimal data visualization and maintenance tracking.

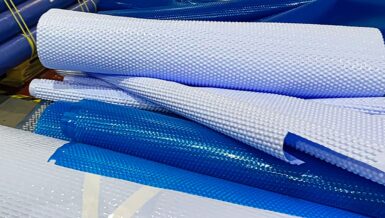

Turn your rails into profitable scrap with Arno®Break and profit from the easier handling of cut rails when it comes to transport and storage.