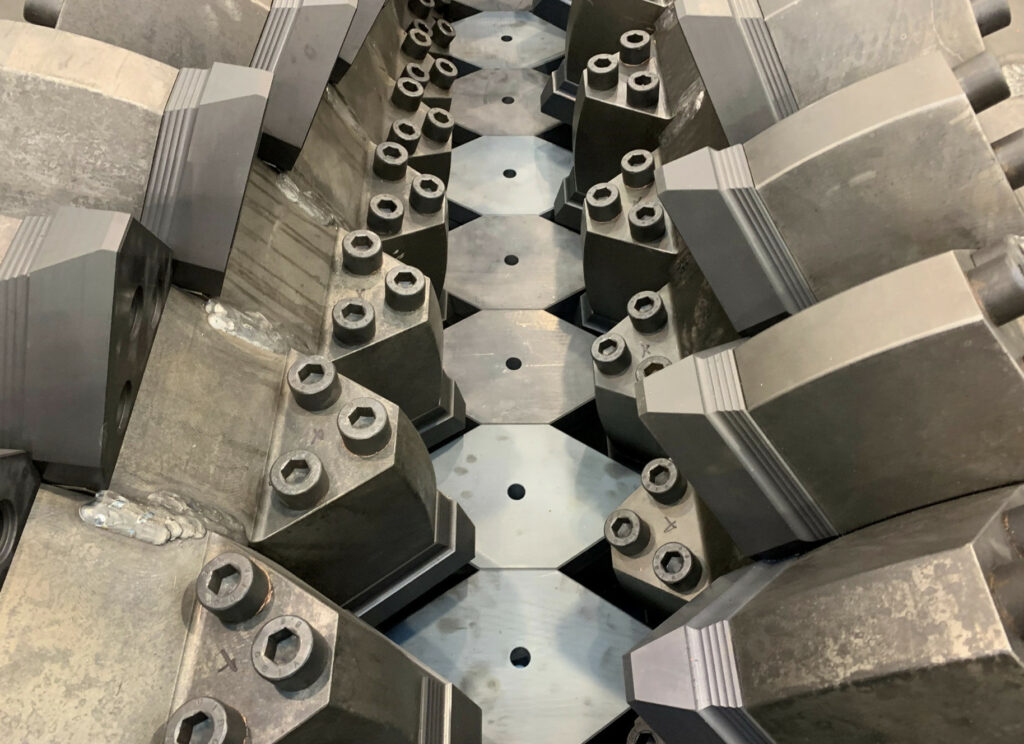

One of the most innovative features of this machine is the fact that it can adjust the distance between the fixed and rotary blades in a simple and quick way. The fixed blades are placed on an adjustable traverse positioned between the two shafts, where the rotary blades are placed. When blades start to wear, it’s possible to reduce the distance between the rotary and fixed ones by simply raising the traverse. These aspects are particularly important when combining energy saving with a clean cut, with few protrusions of steel wires.

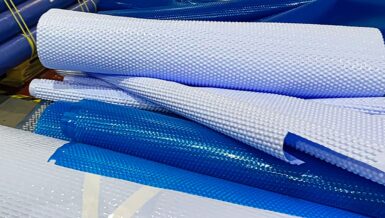

The company has decided to introduce innovations compared to traditional processing schemes. The first innovation is the position of the screen, which is installed directly on the machine, keeping the material in the shredding chamber until it is reduced to the chosen size.

The second and most important innovation is the aforementioned adjustable cutting system, which allows to recover the millimeters of wear lost during processing, maintaining productivity and energy savings constant over time.

Molinari overcame the wear problem with an innovative rotor and blade design. The blades are trapezoidal and have a thickness of 68mm. They are hardened and resharpenable for 20 mm.The robustness of the machine allows it to handle even large tires which could be the subject of interesting opportunities to tackle new market shares.