Thanks to years of experience in the processing of metal-bearing waste materials, the experts from Sonthofen found the optimal machine for processing abrasive materials. Wear costs at Jansen have significantly decreased since.

Residual materials from shredders from automobile recycling are made up of a wide variety of different materials. In addition to plastic, rubber, and textile fibers, ASR contains valuable non-ferrous metals such as aluminum, brass, and copper, as well as mineral components and glass. The latter makes efficient processing difficult, which Jansen Shredder Recycling learned the hard way.

Where it all started: a sophisticated process with a weakness

A sophisticated process should have ensured that Jansen obtains the highest possible yield of recyclable materials – especially metals. First, the heavy particles were separated at the Jansen site by means of a cross-flow separator. The remaining fraction was pre-crushed in the existing granulator. A non-ferrous fraction could then be extracted from the material using eddy current separation. The non-inductive fraction, however, always contained valuable non-ferrous metals in addition to plastics and minerals. These non-ferrous metals were copper cables and other metal composites. Up until this point, Jansen used fine-grinding mills directly after eddy current separation to recover this fraction of the remaining metals. However, this is exactly where the weakness in the otherwise sophisticated procedure stemmed from: the wear costs of the fine-grinding mills used were unexpectedly high. These machines were designed for use with abrasive components. Glass and mineral components resulted in wear costs of €35 per ton of input material. The profits from the recovered metals could not make up for these losses. This meant a new solution was required.

Implementing expertise from rock crushing in the ASR recycling process

Jansen Shredder Recycling turned to BHS-Sonthofen. The Dutch company was already familiar with the rotor impact mill (type RPMX) from BHS. In order to ensure that the mill from BHS was capable of pulverizing abrasive materials and dissolving and pelletizing non-ferrous materials, Jansen traveled to Sonthofen with the original input material and performed the corresponding tests with the recycling experts onsite.

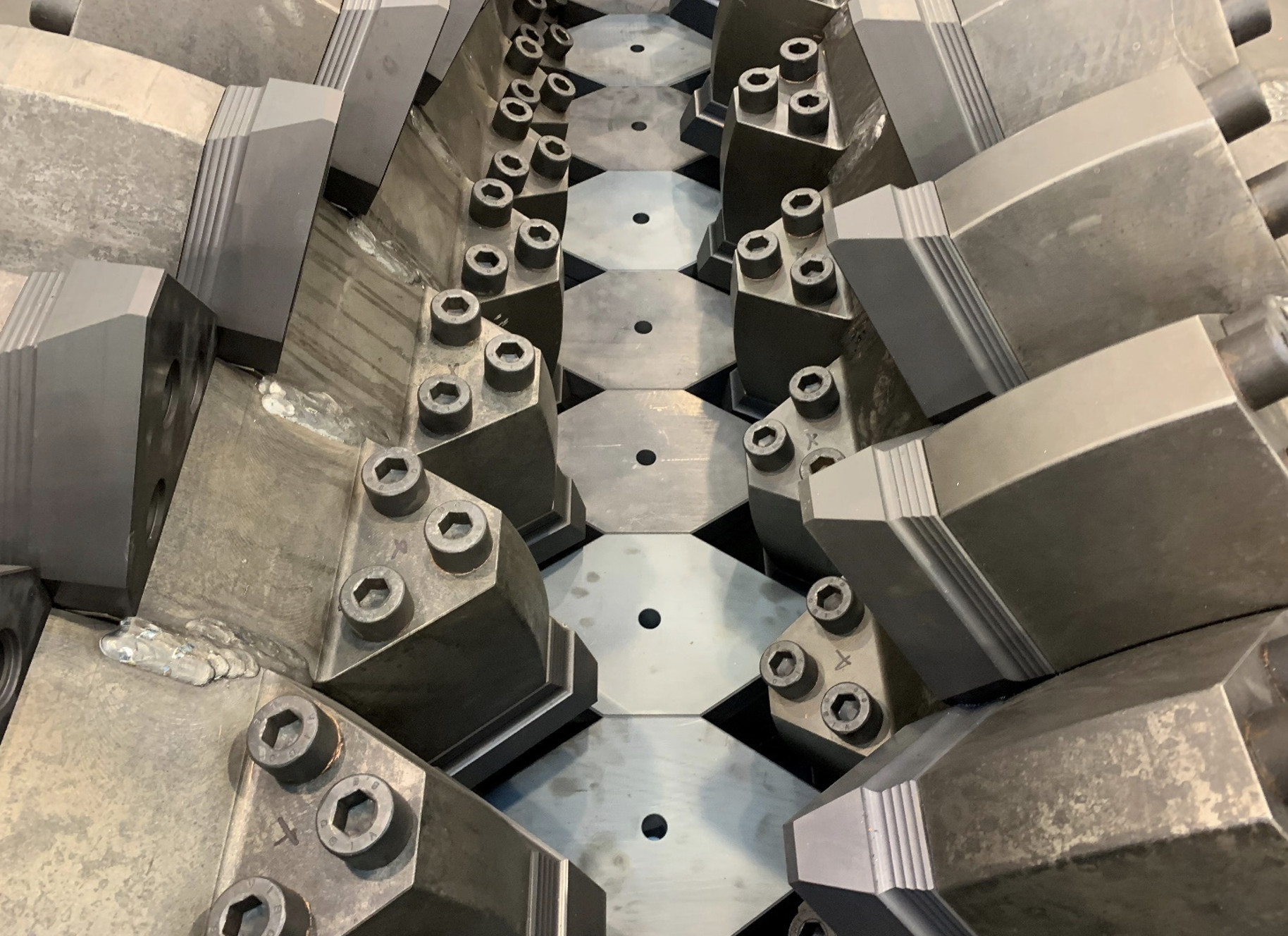

Originally, the rotor impact mill comes from the stone and earth sector: The model’s RPM und RPMF were used for the targeted shredding of abrasive materials, such as river gravel. The RPMX was specially optimized for the recycling industry. Due to its solid construction and chilled cast chrome wear parts, it is extremely resistant, and, therefore, ideal for processing ASR fractions, as is done at Jansen Shredder Recycling.

As it turned out, results were convincing. The mill reliably destroyed glass and minerals. “In many cases, the material only needs to be run through our RPMX once to achieve the desired shaping and be able to separate the material on air separation tables,” explains Nikolas Kaufeisen, Area Sales Manager in the Recycling & Environment division at BHS-Sonthofen. “If pelletizing requirements are not met after the first run-through, the material can be run through the rotor impact mill a second time.” At Jansen Shredder Recycling, the decision was made not to recycle the material and to carry out the last pelletizing step in the existing fine-grinding mill. “Adding the rotor impact mill from BHS to the process as an intermediate step resulted in a significant increase in profits,” reports Hans Brekelmanns, Managing Director at Jansen Shredder Recycling. “We were able to lower wear costs by approximately 75 percent overall.”

The rotor impact mill was integrated into ASR processing at Jansen Shredder Recycling BV in March 2019. This has increased the efficiency of the entire process. They were also very happy with the consultation provided by the experts from BHS and more joint projects have already been planned.