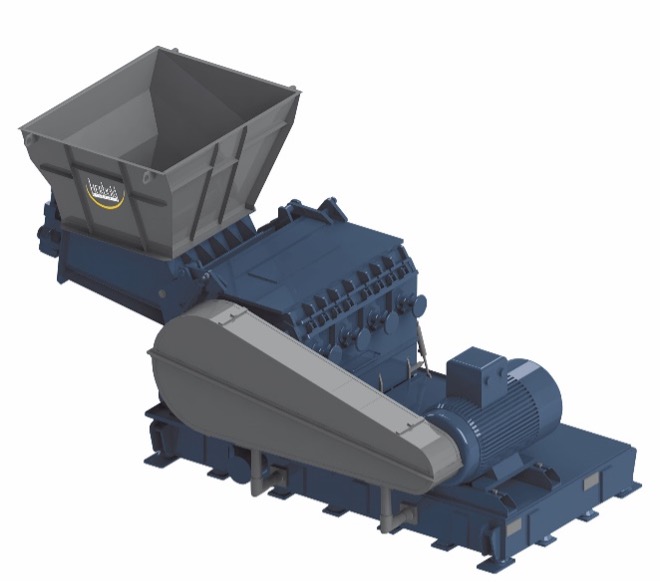

In the case of heavy-duty applications, if powerful machines are needed, only very few providers of size-reduction equipment on the market will be able to present an appropriate answer. Herbold granulators will do the job of all plastic waste. The key for the efficiency of the Herbold granulators is the rotor design and the special construction design of the granulators in addition to the cutting geometry and the real double cross-cutting action. Herbold can offer a multitude of rotor geometries, customized according to the individual application. The entire anti-wear coating of the housings and the exchangeable wear parts of special rotors have scrupulously been thought out and guarantee a long service life of the machines, easy to maintain.

Washing technology

The demand for high-performance and efficient recycling plants is currently extremely high. Projects covering investments of up to 12 million keep surging and high-end product qualities are in the focus. The use of hydrocyclones in separation technology and the hot wash have been important components of the HERBOLD plant solutions and vital criteria of Herbold technology for years. Herbold managed to almost double the business in the last 2 years.

Especially for the following applications, Herbold is able to offer tried-and-tested solutions:

- Post-industrial post-consumer film

- Post-consumer rigid plastics

- PET bottles

- PET trays

- Big-bags and other monofilaments

- Bottle crates and pulper residues

The hot wash of film has by now become an essential component in a multitude of orders to yield the wanted high qualities of post-consumer materials. In the PET realm, plant technology continues to be set on efficiency and product output. We can also showcase efficient solutions for PET trays and due to gentle treatment, only a few fines are lost in this brittle material flow.

Herbold technology can also be used as a preliminary processing step for chemical recycling. Dry cleaning solutions, wash lines as well as Herbold agglomerators tailor the input material for the chemical procedure solution.

“We are committed to a competent and comprehensive consultation of our customers,“ highlights Achim Ebel, Division Manager for Washing Lines – A ready-made washing line does not exist at Herbold, in cooperation with our customers, it is an individual process to devise a corresponding solution in response to the application.