Magnetic Separator Efficiency Criteria

Magnetic separator efficiency criteria depends on the task at hand.

- For iron separators it is important to achieve the maximum percentage of extraction of impurities of a certain size that can harm or damage crushing, grinding or other equipment. Taking into account the operating conditions (height of the product layer on the belt, conveyor speed), a separator model that can remove the required dimensions is selected.

- Separators recovering saleable magnetic fraction in the form of scrap metal, iron ore concentrates, dense medium solids, ferroalloys, etc., must ensure the required content of the valuable component in the separated product. It means that the quality of magnetic separator operation with removal of non-magnetic impurities, host rock, slag, will affect the quality and cost of the finished product.

- Another criterion for evaluating how effective this type operates is the loss of a valuable product with a nonmagnetic fraction (tailings). It is often impossible to avoid losses of magnetic material completely due to variability of conditions and material composition, but a properly selected separator will reduce this indicator to minimum values.

For example, if ERGA WetMag R wet magnetic separator for dense media recovery operates correctly, losses of dense medium solids will be only 0.5 g per liter of the processed suspension.

Properties, composition of the separated product and operating conditions

When choosing a magnetic separator, it is also necessary to take into account properties, composition of the separated product and its operating conditions:

1. Product size

The separator type of and its overall characteristics are selected considering the product size. Maximum product size can reach 400 mm, minimum size is 20-10 microns. For processing lumpy material separators with increased safety margin are selected (ERGA DrumMag C, ERGA DrumMag M).

2. Product temperature

Magnetic system alloy is selected depending on the temperature of material. Standard permanent rare earth magnets have operating temperatures up to 60° C. For separation of material from 60° C to 200° C, Nd-Fe-B alloys with dysprosium and terbium are used. Magnet alloy based on Sm-Co is used for higher temperatures up to 300° C.

3. Product moisture

For dry magnetic separation moisture content of the separated product is an important factor. This indicator for the product size less than 10 mm should not exceed 5%, for the product size less than 1 mm – 0.5%, for the product size less than 0.1 mm – 0.1%. At high moisture quality of separation decreases due to adhesion and sticking of particles to the separator surface; therefore, it is recommended to pre-dry the material.

4. Magnetic susceptibility of particles

Magnetic induction in the operating area is selected depending on magnetic susceptibility of the particles. For ferromagnets, separators with low intensity of magnetic field (up to 0.32 T) are installed, for paramagnets, depending on the task, separators with average (0.32-0.9 T) and high intensity of magnetic field (0.9-1.5 T) are installed.

5. Content of magnetic impurities

Percentage of magnetic impurities and inclusions will determine the type of separator cleaning. With low content (less than 0.5%) separators with manual cleaning can be installed. With an increased content of 0.5-5%, it is recommended to use mechanical cleaning – this will save the operator’s time on the process of preparing the equipment for separation. The content of magnetic impurities more than 5% in the product leads to rapid blockage of the operating area and requires continuous or periodic automatic cleaning.

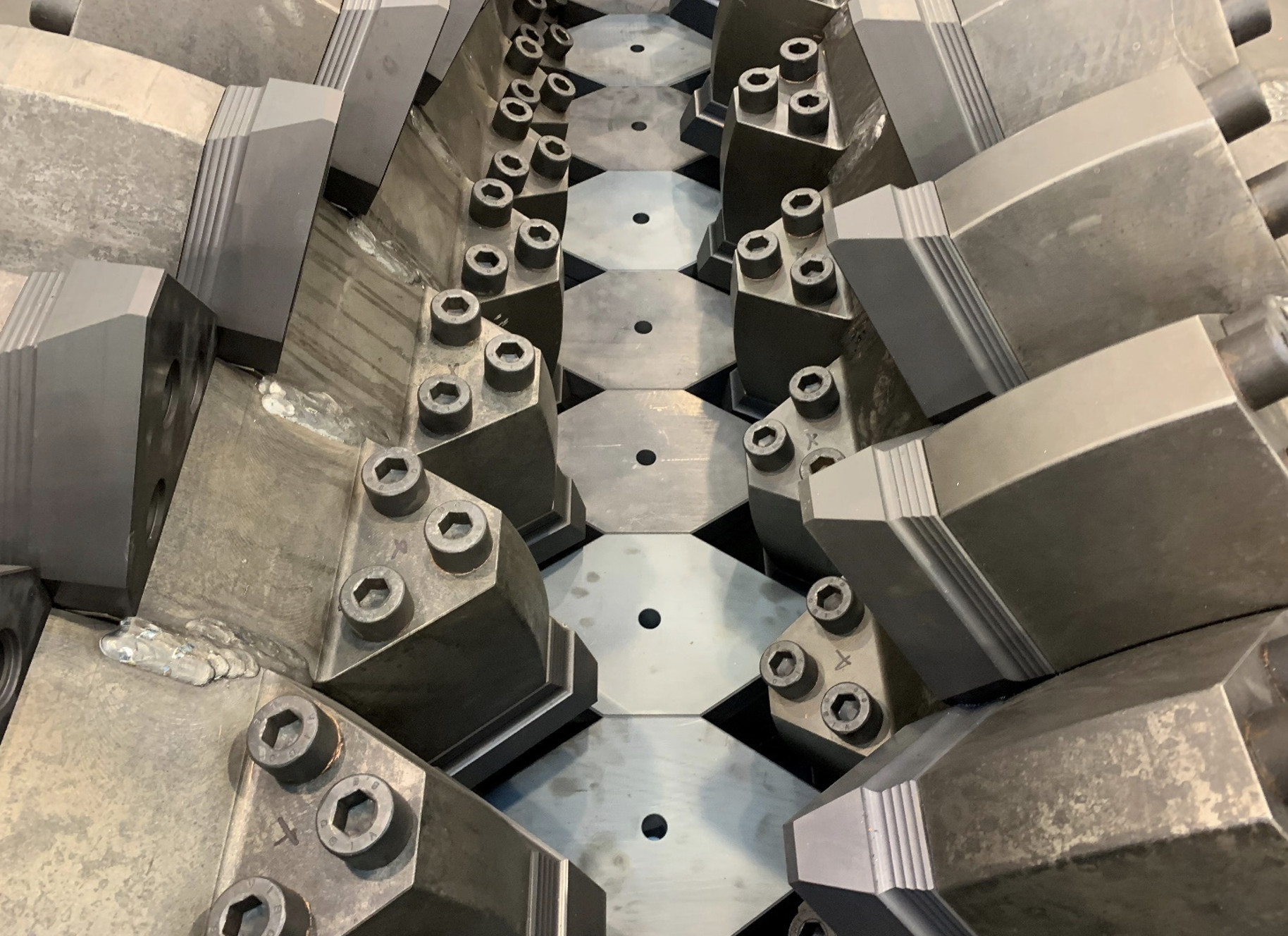

Caution! Tricks of unscrupulous manufacturers

Due to availability of Chinese magnetic materials the number of manufacturers is increasing, unfortunately, unlike the quality of the produced separators. In pursuit of superprofits manufacturers who do not have proper experience in manufacture and design of magnetic equipment often neglect such necessary conditions as control of the production process, manufactured parts, and magnetic characteristics. Below are the most common cases when such manufacturers save on the quality of equipment, and, therefore, on separation efficiency, for the sake of short lead time and low cost.