HSM develops, produces and sells products and systems for compressing materials as well as for shredding paper and electronic data media. Hermann Schwelling Maschinenbau GmbH + Co. KG was founded in 1971 in Salem and started a year later with the sale of the first baling press for cardboard. Like many other successful companies in the world, the development of the company began humbly in a small workshop.

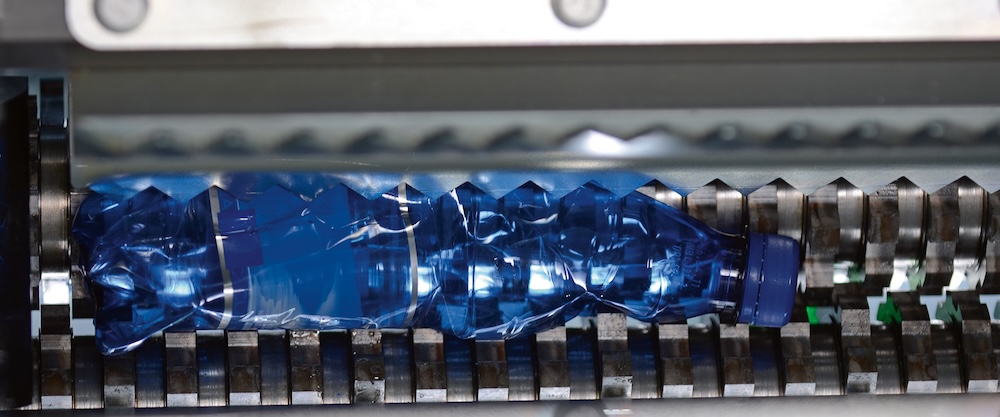

Today the office technology product range includes document shredders, digital data media shredders, shredder-baler combinations and packaging machines. In the corporate division environmental technology, the portfolio includes vertical and horizontal baling presses for retailers and manufacturers, shredder baler combination machines, PET/UBC compaction technology, fully automatic baling press systems up to a pressing power of 150 tons for professional waste disposal companies and individually projected facilities or special solutions.

The portfolio also includes configuration and implementation of system solutions for shredding and pressing various valuable products such as paper, foil, cardboard, composite materials, PET, foams, car tyres, hard plastics etc. HSM has three manufacturing plants in Germany (Salem, Frickingen, Reichenbach). There are subsidiaries in the USA, England, France, Poland and Spain. In a worldwide distribution network, HSM employees collaborate with sales and service points in more than 100 countries.