The shaking table is an old and reliable technique widely used in the mining and recycling industry.

The shaking table, also known as gravity separation, has different relative movements against gravitational forces, depending on factors such as weight, particle size, and shape by taking advantage of the density differences between mineral particles.

How does a shaking table work principle?

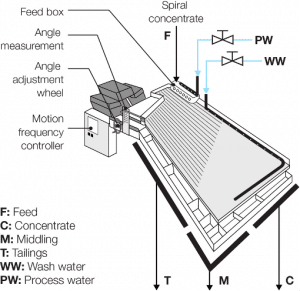

Shaking tables are rectangular-shaped tables with ribbed decks with a water film flowing on them. Water flowing along the long axis of the table slurries the fed sample. Low-density particles are transported in the fast-moving film, causing fine, high-density particles to fall into the beds behind rifles. With the rapid backward movement of the table, the particles gain a forward movement thanks to momentum, so each structure is separated from the other. Separation performance in shaking tables is directly related to particle size distribution.

Therefore, the narrower the grain size of the material, the better the separation performance. Wilfley and Gemini type shaking tables appear with different models in the recovery of precious metals, in gold mines, and in electronic waste recycling processes.

What is the importance of the shaking table in the e-waste recycling industry?

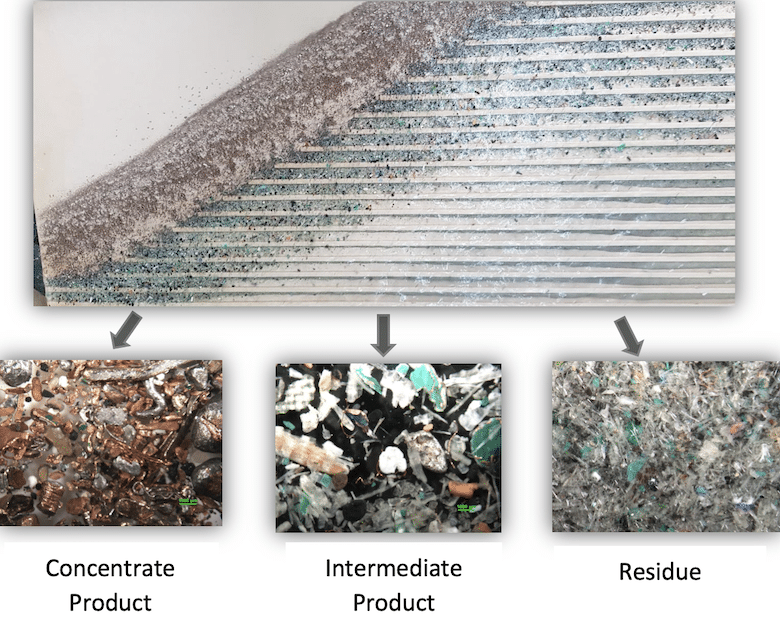

The shaking table used in the beneficiation of the mine field has the feature of separating precious and rare metals, especially in the structure of complex electronic wastes, from glass fiber and other plastic structures according to the density difference.

It is divided into three as concentrate, intermediate, and residue. In the chemical process, metals in concentrates and intermediates can be obtained more easily with high purity, while the residue, which is thought to be plastic and its derivatives, can be evaluated in another recycling process.

Proses Makina Company has minimized the leaks that may occur in the physical process with the innovations it made in the shaking table in addition to the chemical solutions it offers in mining and recycling. We continue to provide the needs of our customers in this adventure that we set out with the vision of zero loss!