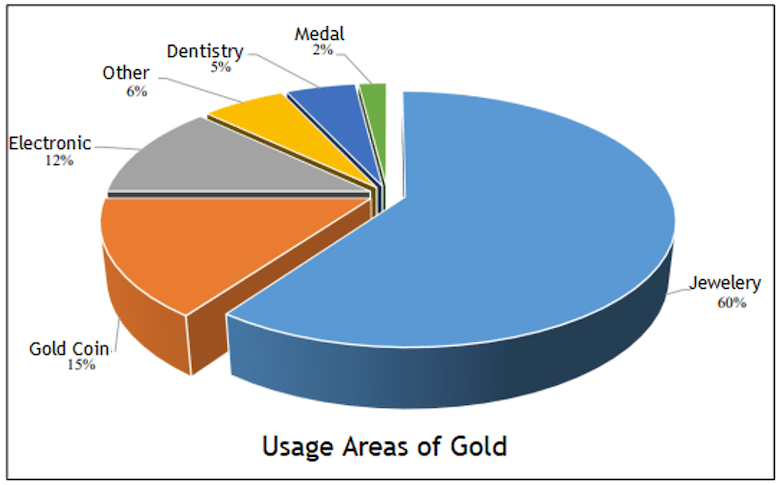

As human history progresses, it has become a symbol of power and wealth. In this instance, being a gold producer and having primary and secondary resources mean an economic factor. Today, its place in the industry is indisputable. In the figure below, it is seen that it is widely used in various fields, mostly in the jewelry sector.

Recovery is the process of removing impurities from precious metals. Through the recovery and refining systems offered by Proses Makina, you can have the right information, materials and equipment. Besides, you can easily refine precious metals with high purity such as gold, silver and more metals from mine which is a primary source and scrap jewelry which is a secondary source.

Gold Refining from the Mine

Ores are used as the primary source in the production of a gold metal, whose value is increasing day by day. Precious metal reserves are processed, enriched then refined to obtain high purity gold. As Proses Makina, our gold production system provides that you can recover precious metal with high efficiency. At the same time, through to our neutralization unit, you can smoothly carry out environmental precautions according to national and international standards, which are the most important factor.

Gold Refining from the Jewelry Scrap

As seen in the usage of the gold chart, gold is widely used for jewelry and ornaments, with its widespread use in many sectors. These scrapped products constitute an important secondary source in terms of the metals it contains. The vast majority in the jewelry industry brought recovery processes as a necessity.

In the jewelry industry, gold is generally used as silver, palladium, copper or platinum alloys. These scrap jewelry containing many precious metals need to be recycled. Through our recycling and recovery systems, it is possible to obtain all the metals contained in scrap jewelry in 100% efficiency. It is our guarantee that you can recover 99.99% purity Au and other metals with a minimum purity of 99.95%.

What is Gold Smelting?

Smelting gold is the process of extracting gold from the ore it is combined. After smelting, the gold has around 90 % purity. It still contains other metals like silver, copper, aluminum or iron hence that it is not acceptable for the market.

What is the difference of Gold Smelting and Melting?

Gold melting is simply turned the gold into a liquid form by heating. Then it is possible to make forming gold bars.

Smelting Gold is a more complex process. This process involves the removal of impurities from gold using heating, pressure and various chemicals. When the smelting process is over, the gold is poured into bars for transport to the next process.

In gold extraction, it may have to be refined before being put to use. Refining gold is simply the process of removing the impurities that the smelting process could not remove. There are many gold refining methods.

What is the aqua regia?

Aqua regia, also known as royal water includes a mixture of hydrochloric acid and nitric acid, respectively. Aqua regia can dissolve many metals that are normally very difficult to dissolve. These metals are known as noble metals.

Aqua regia is one of the strongest acids and is capable of dissolving Au and Pt. Aqua regia can rapidly attack gold. Platinum is attacked by aqua regia and mixtures of hydrochloric acid and oxidizing agents.

How to recover gold from aqua regia?

The aqua regia is one of the methods gold recovery process. It is preferred more because of the chemical is found easy and cheap. To prepare aqua regia we need to mix one part of nitric acid and three parts of hydrochloric acid. Especially the gold can recovery from e-waste, mining and scrap jewelry in this way. any precautions are taken to ensure the complete recovery of gold from the aqua regia solution, and, the correct choice of the gold reducing chemical is also a very important part of this gold recovery process.

As Proses Makina Team,

One of these solutions, we eliminate the red fume and waste problem caused by gold refining with the chemical solutions it offers. One of these machines, the scrubber unit aims to wash the acid gases that will occur during chemical leaching and make them harmless in terms of environment and human health in legal emission limits.

One of the other machines is our leach reactors made of titanium or polypropylene that can rotate around its own axis and resistant to aqua regia.

We provide physical and chemical solutions according to our customer’s demands. We are guaranteed %99,99 purity gold recovery from mining, e-waste and scrap jewelry.