Many more applications have been proven, like

Extraction of Mg Alloy from Mixed Light Fraction (Twitch/Zorba)

Sorting 6xxx from 5xxx series Al Alloy Scrap

Extracting 7xxx from Shredded Old Rolled

Extracting 6082 from Profiles Scrap

Extracting High Cu Cast Al Alloy from Low Cu Cast Al Alloy

Sorting 6082 and 7xxx series in mixed Al Wrought Scrap

Sorting 6082 from 6063 in Mixed Al Wrought Scrap

Extracting Cast Al Alloy from Shredded Old Rolled

Extracting High Fe Cast Al Alloy from Low Fe Cast Al Alloy

Extracting 1xxx series from mixed Al scrap

Sorting Zorba heavies by alloy class: Cu, Brass, SS, Zn, etc.

… and even more

Besides the significant growth of Aluminum consumption worldwide, most countries show significant efforts to increase their Aluminum recycling quotas, too. Aluminum is the most cost-efficient base metal in terms of processing for re-use. The key is to use this concept in terms of re-melting—that is, melt specifically the scrap that is the desired alloy of production—and save money and carbon footprint loads as a result.

So far, the sorting technologies used in Aluminum recycling are generally based on physical properties, just like density characterization by XRT (X-Ray Transmission). It is known that these physical characterization techniques are not able to recognize most elemental alloying differences that make up the wide variety of characteristic inter-, and intra-alloying classes.

In terms of chemistry-based sorting, XRF (X-Ray Fluorescence) as a sensor has proven inadequate for most light fraction alloys such Cast and Wrought Aluminums, Magnesium- and Titanium-based alloys.

LIBS (Laser Induced Breakdown Spectroscopy) has been developed over many years of R&D to yield key advantages in light metal sorting. It has proven the ability to sort fine differences of alloying elements of interest such as Fe, Mg, Mn, Cu, Zn, etc. Differentiation of these in the in-feed scrap metal loads has the utmost of importance when dedicated recycling processors need short furnace turns.

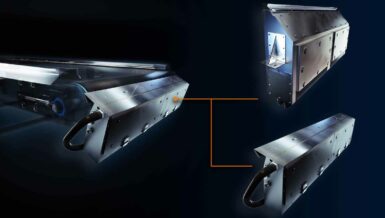

Among Austin AI’s product portfolio, you will find our flagship- the LIBS based sensor sorting technology, which is a key part of Aluminum recyclers’ sorting line. LIBS enhances the added value of sorted fractions – aiming for zero carbon emissions and circular economy. Our newest R&D plan is to design and manufacture a unique sensor sorter for black plastic sortation.

Austin AI, or Austin Automation and Instrumentation is headquartered in Austin, TX, USA. We have a wide clientele throughout the Americas, and our new sister location, Austin AI (EU), based in Budapest, Hungary, represents clientele throughout Europe, the Middle East and Africa. Austin AI was founded by Rick Comtois over 20 years ago with the goal to develop and manufacture advanced Sensor Sorters based on spectroscopy.

We are also pleased to inform you that ISRI 2022 will take place between March 21-24 at the Mandalay Bay resort & casino in Las Vegas, Nevada. Austin AI, as a committed supporter of sustainability, will be present at the exhibition and we would love to meet you. We will be located at booth 1110.

This year, all qualified visitors will be entered into a raffle for the chance to win a free flatscreen TV. The eligible winner must be able to arrange shipping or other means of taking the TV home with them. Please book a time for your visit via email (info@austinai.com) and our team will be happy to enter you into our raffle and give you more details about our Sensor Sorters, as a Best Available Technique (BAT) for metal recyclers, the foundry industry, and more. We’re looking forward to meeting you!

Create high added value from your aluminum scrap!

Please contact us to learn more:

AAI USA

Austin, Texas, USA

www.austinai.com

info@austinai.com

+1-512-837-9400

AAI EMEA

Budapest, Hungary, EU

www.austinai-eu.com

info@austinai-eu.com

+36 309 545 146