1. Introduction

The recycling of metals, particularly copper, is critical for sustainable resource management due to its widespread use in electronics, construction, and renewable energy systems. Efficient extraction and purification of copper from recycled materials require precise analytical techniques to determine composition and quality. Laser-Induced Breakdown Spectroscopy (LIBS) has emerged as a powerful tool for elemental analysis in metal recycling, offering real-time, non-destructive testing with high sensitivity. This paper examines the application of LIBS in copper extraction from recycled metal, highlighting its technical advantages, practical applications, and potential to transform the recycling industry.

The Opportunity

There is a problematic scarcity looming for copper. By 2030 global copper mines will only meet 80% of the worlds copper requirements accordingly to the International Energy Agency and as reported by the Week US and United Nations. The reasons include the difficulty and expense in mining it and the surging demand set to rise more than 40% by 2040. The element is used practically everywhere, in homes, factories, electronics, automobiles and in power generation. Off-shore wind turbines require almost three times as much copper as does coal-fired powered generation. The average EV typically requires over 132 pounds of copper vs. 52 pounds for the average gas-powered car. So, between EVs, wind turbines and other copper-powered technologies, retooling power and transportation systems to run on renewable energy will require far more copper than the companies that produce it are currently committed to deliver, according to Bloomberg.

With new mining projects facing long lead times, recycling is emerging as a vital part of the solution,according to the United Nations Trade and Development body, UNCATD.

2. Principles of LIBS Technology

Laser-Induced Breakdown Spectroscopy is an atomic emission spectroscopy technique that uses a high-energy laser pulse to create a plasma on the surface of a sample. The plasma emits light at wavelengths characteristic of the elements present, which is analyzed to determine the sample’s elemental composition.

2.1 How LIBS Works

- Laser Ablation: A laser beam is focused on the sample, vaporizing a small amount of material and forming a high-temperature plasma.

- Plasma Emission: As the plasma cools, excited atoms and ions emit light at specific wavelengths corresponding to the elements in the sample.

- Spectral Analysis: The emitted light is collected and analyzed using a spectrometer, producing a spectrum that identifies the elements and their concentrations.

The process is rapid, typically taking micro-seconds, and requires minimal sample preparation, making it suitable for high-throughput industrial applications.

2.2 Key Components of a LIBS System

- Laser Source: Provides the energy to generate the plasma.

- Optical System: Focuses the laser and collects emitted light.

- Spectrometer: Analyzes the emitted light to produce spectral data.

- Data Processing Unit: Interprets the spectra to quantify elemental composition.

3. Application in Copper Extraction

Copper is a critical material in various industries, and its recycling from scrap metal is essential for reducing environmental impact and conserving resources. LIBS facilitates copper extraction by providing rapid and accurate analysis of recycled metal samples.

3.1 Sorting and Quality Control

LIBS enables the identification and sorting of copper-containing alloys in mixed metal scrap. By analyzing the spectral signatures, LIBS can distinguish copper from other metals (e.g., aluminum, iron, or zinc) and determine alloy compositions. This capability ensures that only high-purity copper is selected for extraction, improving process efficiency.

3.2 Impurity Detection

Impurities such as lead, tin, or sulfur can compromise the quality of recycled copper. LIBS detects trace elements with high sensitivity, allowing operators to identify and remove contaminated materials before processing. This reduces the risk of producing substandard copper products.

3.3 Process Optimization

In copper extraction, LIBS can monitor the composition of molten metal in real-time, enabling adjustments to smelting and refining processes. This ensures optimal copper yield and minimizes energy consumption.

4. Advantages of LIBS in Copper Recycling

- Non-Destructive: LIBS requires minimal sample preparation and does not damage the material.

- Rapid Analysis: Results are obtained in micro-seconds, supporting high-throughput operations.

- Versatility: LIBS can analyze solids, liquids, and gases, making it adaptable to various stages of the recycling process.

- Cost-Effective: Reduced need for chemical reagents and complex sample preparation lowers operational costs.

- Multi-Element Detection: LIBS simultaneously detects multiple elements, providing comprehensive compositional data.

5. Challenges and Limitations

Despite its advantages, LIBS faces challenges in industrial applications:

- Matrix Effects: The sample’s physical and chemical properties can affect plasma formation and spectral accuracy.

- Quantitative Precision: While LIBS excels in qualitative analysis, achieving high quantitative accuracy requires calibration with reference standards.

- Equipment Costs: High-quality LIBS systems can be expensive, posing a barrier for smaller recycling facilities.

- Environmental Sensitivity: Dust, humidity, and temperature variations can impact measurement reliability in industrial settings.

6. Future Prospects

Advancements in LIBS technology are addressing current limitations and expanding its potential in copper recycling:

- Machine Learning Integration: Algorithms can enhance spectral analysis, improving accuracy and reducing matrix effects.

- Miniaturization: Portable LIBS systems are being developed for on-site analysis, increasing accessibility.

- Automation: Integration with robotic sorting systems can streamline recycling workflows.

- Hybrid Techniques: Combining LIBS with other methods (e.g., X-ray fluorescence) can improve quantitative precision.

7. Recommendations for Implementation

To maximize the benefits of LIBS in copper recycling, stakeholders should:

- Invest in robust LIBS systems with advanced data processing capabilities.

- Develop standardized calibration protocols to ensure consistent results.

- Train personnel in LIBS operation and data interpretation.

- Integrate LIBS with automated sorting and processing systems to enhance efficiency.

- Collaborate with research institutions to explore innovations in LIBS technology.

8. Conclusion

Laser-Induced Breakdown Spectroscopy offers a transformative approach to copper extraction from recycled metal, providing rapid, non-destructive, and versatile elemental analysis. Its ability to enhance sorting, detect impurities, and optimize processes makes it a valuable tool for the recycling industry. While challenges exist, by adopting LIBS, the recycling industry can achieve greater efficiency, sustainability, and profitability in copper recovery.

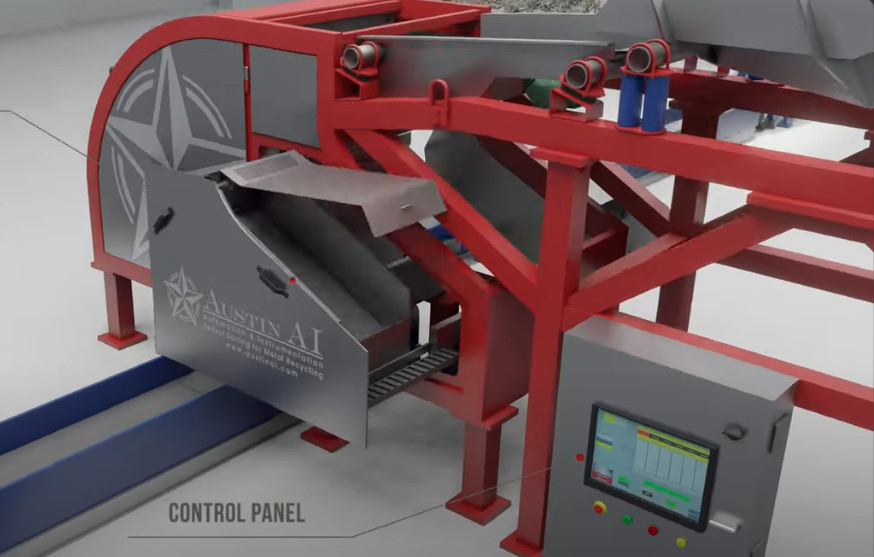

Dedicated to the Science of Recycling

As a pioneer and industry leader in the science of laser-induced breakdown spectroscopy (LIBS) technology, Austin AI, Inc., with offices and facilities in Austin Texas and Budapest Hungary, has built a reputation on systems with greater scrap sorting efficiency resulting in reduced processing times, lower energy costs, greater material purity, while promoting sustainability.

References

- Cremers, D. A., & Radziemski, L. J. (2006). Handbook of Laser-Induced Breakdown Spectroscopy. Wiley.

- Noll, R. (2012). Laser-Induced Breakdown Spectroscopy: Fundamentals and Applications. Springer.

- Singh, J. P., & Thakur, S. N. (2017). Laser-Induced Breakdown Spectroscopy. Elsevier.

- Mishra, Vibhu, Economic Development United Nations News, (9 May 2025). UN Warns Copper Shortage Risks Slowing Global Energy and Technology Shift

- Klawans, Justin, (June 12, 2024), A Massive Copper Shortage is on the Horizon, Under The Radar – TheWeek.com