Shredders and crushers are always the key equipment in a complete plant. Since the 1980’s, BMH Technology has delivered hundreds of shredders and crushers. These robust machines can process various waste streams, from municipal solid waste to industrial and commercial waste, into alternative fuels and recyclables.

“Our TYRANNOSAURUS® shredders and crushers have not been available as stand-alone equipment. Now we are changing this and have set an ambitious goal: we want that customers will recognize us as a leading middle to high-end shredder supplier. We see a high potential in delivering our equipment to locally operating companies in waste and plastic treatment, as well as to larger companies in cement industry”, says Ari Nyrökorpi, SVP of BMH Technology Oy.

The TYRANNOSAURUS® product family is designed for industrial-scale size reduction and the shredders have many advanced features such as adjustable particle size control, ensuring versatility in material output for diverse applications. Especially, the TYRANNOSAURUS® 9900 series primary shredders are world-famous for efficiently processing high volumes of waste into smaller pieces, optimizing subsequent process steps and enhancing overall system performance.

TYRANNOSAURUS® 1200A series FineShredders

Answering to the cement industry’s need to increase the use of alternative energy, BMH introduces the new TYRANNOSAURUS® 1200A series FineShredders, which are optimized to produce RDF/SRF with homogenous and consistent particle size at high capacity and high availability. The worldwide premier of the new fine shredders takes place at IFAT Munich 2024.

These fine shredders are electrically driven, high-speed, single-rotor shredders. They are specifically designed for industrial-scale refining of pre-shredded and sorted solid waste that needs to be reduced to 20–70 mm particle size.

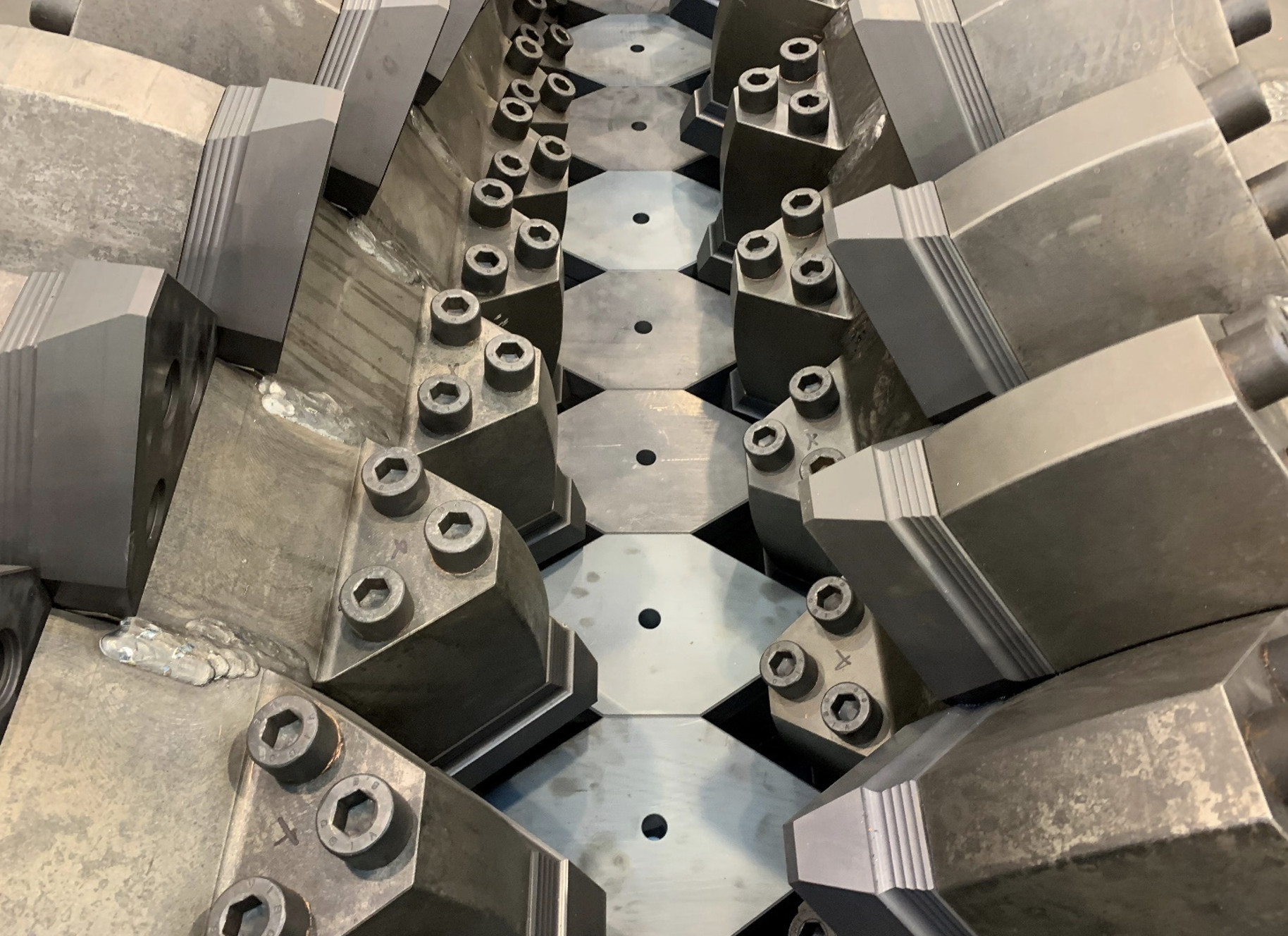

The patented Zero Gap® cutting technology ensures that the capacity, particle size and quality are preserved even when the knives start to wear. Each 800 mm section of the counter knives can be adjusted independently to maintain the cutting gap in minimum, ensuring optimal cutting.

The Impact Protection™ function is based on counter-knives that are held in position hydraulically. This allows for an easy and fast removal of unshreddable materials and effectively prevents damages to the shredder. The screening area has been enlarged by over 50% which enables easier access for the shredded material to pass through the screen.

The rotor has a diameter of 1200 mm and houses 312 knives. Combined with the spiral knife arrangement, optimized knife size and rotation speed, the shredders allocate power effectively to each cutting event and provide an optimal cutting performance. Both ends of the knife can be utilized by turning them 180° which creates a significant saving in operating costs.