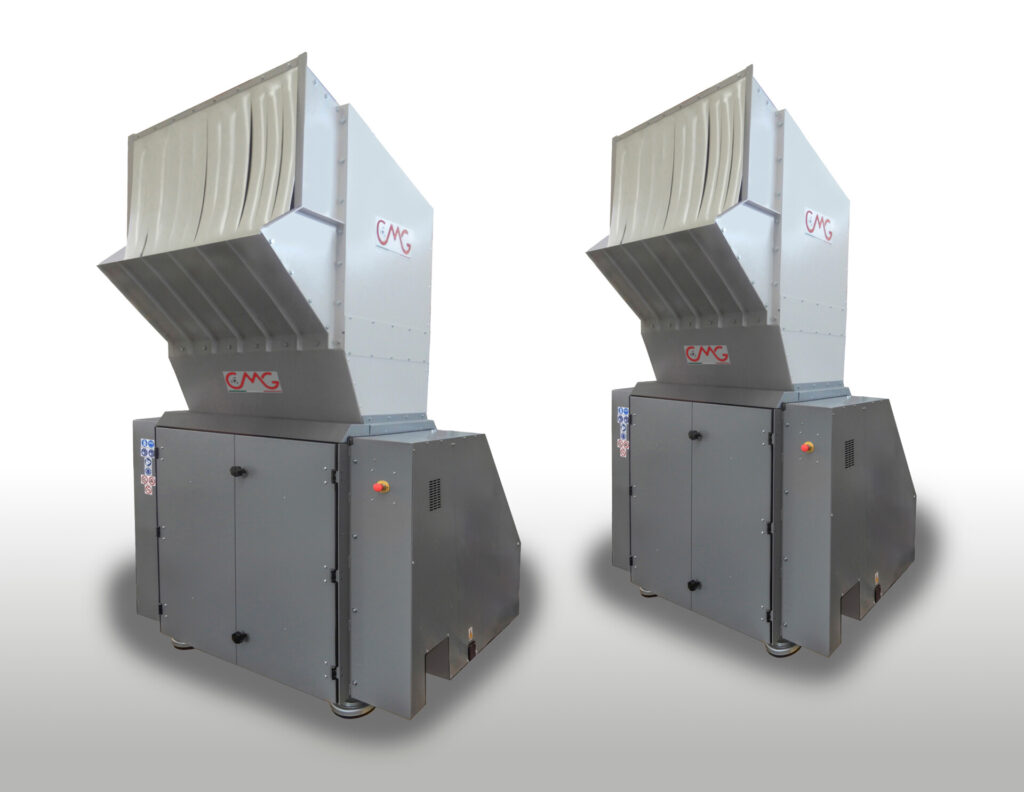

2 Models, several configurations

The new G55 Line is made of two models: G55-90 and G55-120. The line features integral sound enclosure and a very innovative feed hopper design to accommodate the widest variety of shapes and dimensions for the parts to grind. All models operate in high-efficiency conditions, are all equipped with EISA premium-efficiency motors and can have AMP controls (Adaptive Motor Power). Energy utilization is 25 Wh/kg vs the + 50 Wh/kg and more of conventional solutions.

Highly qualitative regrind

The new G55 Line is manufactured with the highest degree of materials and components. The very unique CMG cutting chamber is the signature feature of the new line. Totally assembled from CNC machined steel parts, fabricated with tolerances down to the hundredth of a millimeter, the very high degree of precision of assembly guarantees very accurate cut, dimensional homogeneity of the regrind particles and no generation of dust. Additionally, the high precision of fabrication reduces frictions and abrasions. No cooling water is necessary, irrespective of the application.