With an eye on innovation, leading environmental equipment specialist, Terex Ecotec, continues to expand its world-class range of mobile equipment with the launch of the eagerly awaited TBG 530T. A robust track-mounted high-speed shredder, the TBG 530T is ideal for medium-scale producers requiring an accurate and consistent end product.

Powered by a 493HP Scania DC13 engine, the TBG 530T has been expertly designed to give operators unrivaled performance, ease of maintenance, and superb fuel efficiency. Extremely versatile, it excels in many applications and is particularly suited to waste wood processing and green waste shredding.

Speaking about the latest innovation, Tony Devlin, Business Lines Director for Terex Ecotec said, “The TBG 530T enhances our high-speed shredder offering and allows our product range to further meet operators’ needs. Inspired by the successful TBG 630, the TBG 530T has been purposefully engineered to maintain the same key features in a smaller package. Easy to operate with excellent serviceability we are proud to have it in our portfolio and look forward to it dominating the market.”

With a rapid setup time, the TBG 530T is ready to work in a matter of minutes with no tooling required. The open-fronted feeder enables the TBG 530T to be fed quickly and easily from the rear. The intelligently controlled feed system, comprising of heavy-duty drag chains and aggressive feed wheel with unique lift/downward assist, ensure optimum material flow resulting in class-leading performance.

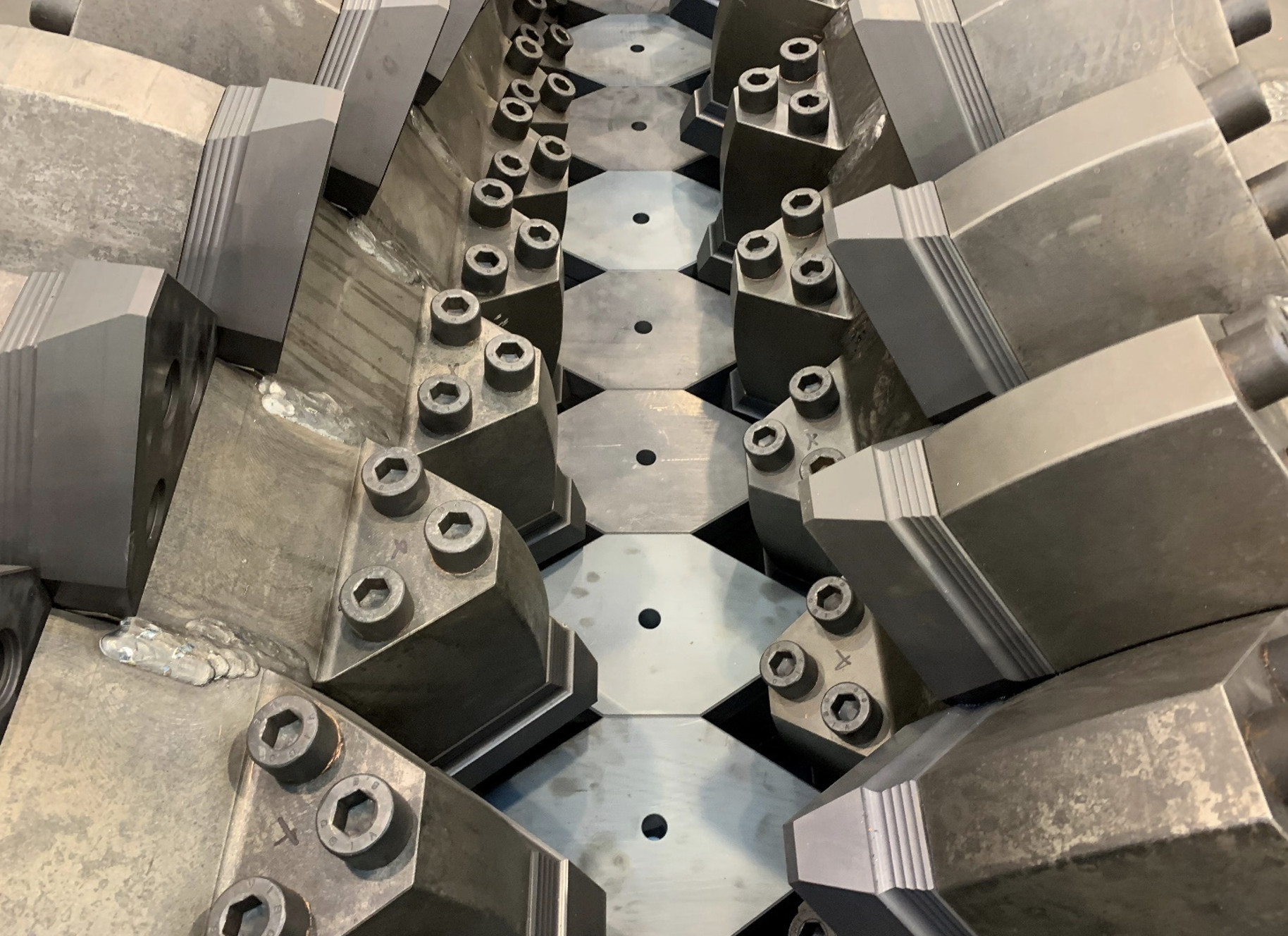

At the heart of the machine is the 1,100mm diameter x 1,490mm wide-swinging hammer rotor. This robust, direct-drive rotor rotates at 1000 RPM and incorporates 30 up-swinging hammers. A wide selection of hammer designs and interchangeable screens are available allowing the machine to be configured to suit the ever-changing product requirements. The TBG 530T also benefits from the added protection of a screen kickback system. Should an unshreddable object enter the shredding chamber the screen will release allowing the material to quickly pass through, reducing the risk of accidental damage.

The processed material is removed from the machine via a modular product conveyor with an impressive discharge height of 4.6m. This conveyor also lowers to ground level for inspection and maintenance. An optional overband magnet with hydraulic height adjustment can be fitted to remove ferrous metal from the product.

Whether performing daily checks or carrying out maintenance, the TBG 530T offers unrivaled service access to all key areas of the machine. The electric/hydraulic raise/lower of the screen and interlocked chamber access door allows the rotor and anvil to be inspected with ease. Designed with the operator in mind, the TBG 530T offers the perfect blend of performance, efficiency, and serviceability.

The TBG 530T comes fitted as standard with the industry-leading T-Link telematics solution designed to improve productivity, efficiency, and profitability for the customer.

Manufacturing of this latest high-speed shredder will take place at Terex Campsie, a dedicated state-of-the-art facility that will support the ongoing growth and development of Terex Ecotec’s ever-expanding product portfolio. The TBG 530T is available to purchase now via Terex Ecotec’s world-class dealer distribution network that provides the sales and aftermarket service demanded in the market.

The addition of the TBG 530T will further enhance an already significant portfolio of products offered by Terex Ecotec and demonstrate their continued passion and commitment for new product development and innovation, positioning them at the forefront of the recycling market.